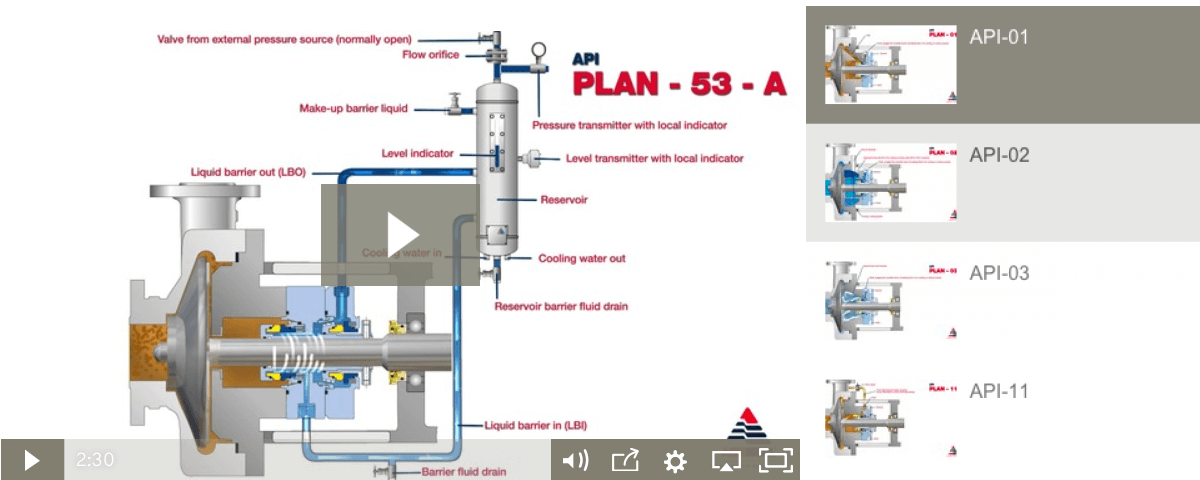

Description

Depressurised buffer fluid circulation in outboard seal of a dual seal configuration through a seal support system. Circulation is maintained by using pumping ring in running condition and by thermosyphon effect in stand still condition.

Features

1. No process contamination.

2. No direct process leakage to atmosphere.

3. No need to maintain pressure system as in Plan 53A.

Use

1. For media where product dilution is not allowed but leakage to atmosphere in diluted form may be allowed.

2. Preferred for clean, non-polymerizing media with vapour pressure higher than buffer fluid pressure

(Is also used for lower vapour pressure media).

Caution

1. Keep the sealant vessel vent continuously open, which is necessary to maintain buffer fluid pressure close to atmospheric pressure and vent the vapors to flare.

2. Should not be used in dirty or polymerizing products.

3. A restriction orifice is necessary in vent line to maintain back pressure in pot and facilitate quick release of vapors to flare.

4. Pressure switch setting should be done above minimum flare back pressure in order to avoid false alarms.

5. Never run the system with level in the sealant vessel being at low level as marked on the level gauge.

6. Check for temperature difference in inlet and outlet lines to ensure that circulation is on.

7. Vent the system properly before start up.