Innovation

At AESSEAL® we constantly strive to innovate and improve in everything we do from design and manufacture through to management and technology.

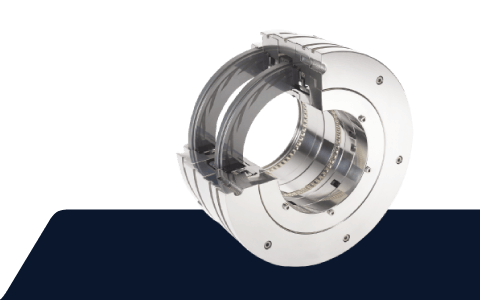

Leading innovative designs such as EasyClean™ and LabTecta®OP IP69K, AESSEAL® embrace the thoughts and ideas of staff to ultimately achieve reliability for our customers.

Improve reliability without modifying your existing equipment.

AESSEAL® has made an enormous investment in modular design which includes custom-engineered specials.

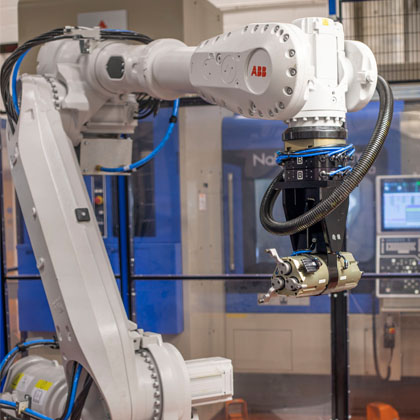

For you, the customer, this means a value-for-money solution and the best on-time delivery performance in the industry. AESSEAL® uses 9 and 11 axis machine tools, each of which have over 300 tool positions, so we can supply your engineered special on demand. In 2021, AESSEAL installed the Super Cell, which is a fully automated robot requiring no intervention leading to increased speed and efficiency.

Design and testing

AESSEAL® is certified to the highest quality standards.

All products are designed in 3D CAD which is fully integrated with CAM. CAM controls and drives all machine tools centrally. Integration with PLM ensures control of changes so products can be delivered quickly, affordably and repeatably.

Our technology

From packing to state-of-the-art dry gas compressor seals.

For every seal developed by AESSEAL® we use the most advanced computational facilities and numerical tools to design and optimize seal performance prior to manufacture and testing.

Tools include Predictive Software Code developed in-house, Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD). Our numercial tools are used for seal design, performance optimization, special product application and troubleshooting. In combination with an extensive test programme the result is world leading technology that keeps your equipment running longer.

AESSEAL has invested in 24/7 AutoStore technology to ensure smooth operation to fulfil world sealing needs.