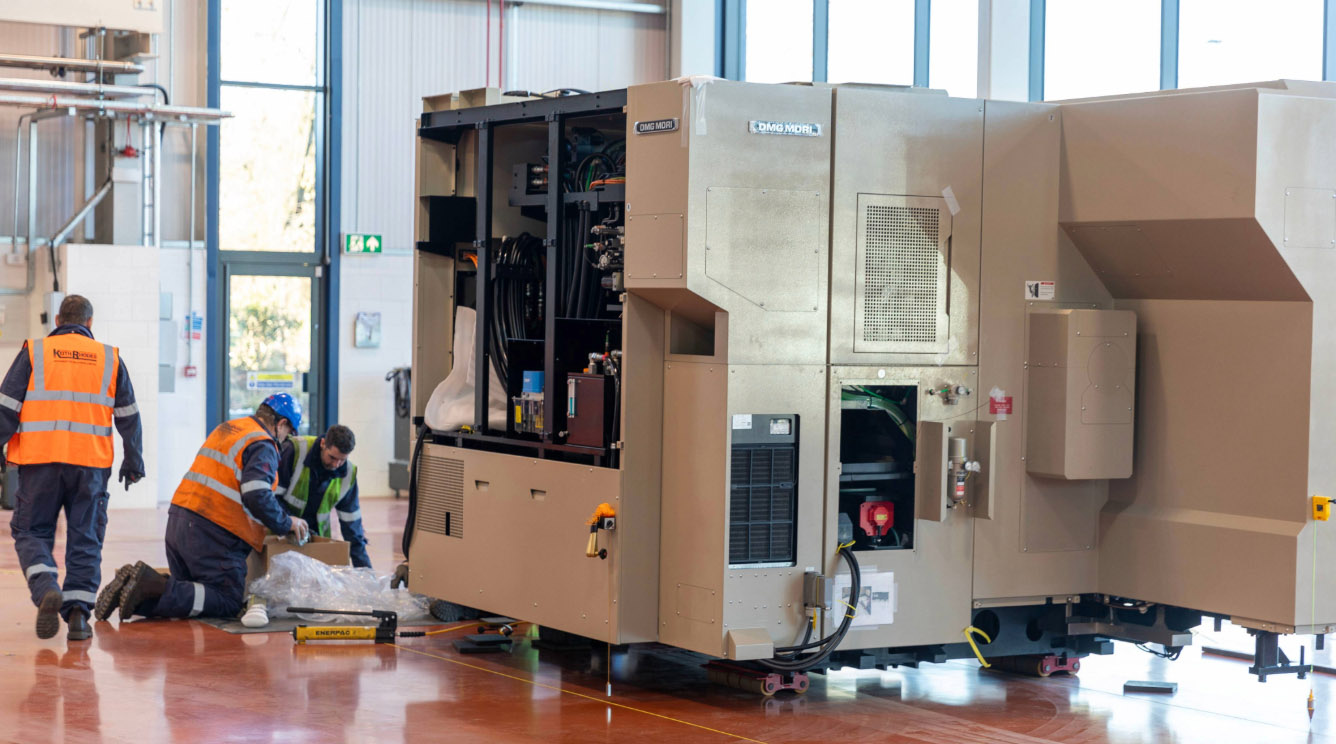

Two state-of-the-art DMG MORI NTX1000 robotic cells have arrived at the AESSEAL Factory for the Future in Rotherham as part of the group’s twin-track plan to invest in technology and staff in order to become the world’s leading reliability business.

These cutting-edge automation cells are the first to arrive following an order for up to six robots costing £7.5 million ($9.3 million) announced earlier this year. They will join the existing robotic cell at Rotherham, which has been in place since 2021.

AES Engineering and AESSEAL managing director Chris Rea said the group’s ongoing investment in AI and robotics went hand in hand with a commitment to future-proofing employment.

Chris also added:

Robotics and AI are ushering in a new age for manufacturing, but people are still the most important driver of business success. We need to give our people the tools, and the training, they need to succeed

The new robotic cells are set for handover to AESSEAL production by the end of March 2025. This timeline includes installation, site acceptance testing, and operator training to ensure a seamless transition into production.

The DMG MORI NTX1000 cells represent a closed-loop automation system. Each one is equipped with a barfeed system, CNC machine, IMTR (In-Machine Travelling Robot), turnover station, FANUC robot, wash and dry system, CMM (Coordinate Measuring Machine) and parts stocker.

The machine tools are 9-axis mill/turn machines with impressive capabilities, including 114 upper tools and 16 lower turret tool slots. These cells are designed to manufacture parts with diameters below 90mm from bar stock, ensuring precise and efficient production.