- Home

- Locations

- Australasia

- Australia

Australia

Related News For This Country

Net Zero HQ is Australia’s number one for sustainability

AESSEAL Australia’s new Net Zero headquarters building has been hailed as a major commitment to a sustainable future for employees and customers in the country.

DMSF seal saves thousands for Australian company

An Australian mining company saved more than AU$20k (US$12,700) in just five months after replacing inefficient gland packing with the AESSEAL DMSF double cartridge mechanical seal.

AESSEAL first in Australia with BREEAM certification

AESSEAL Australia has announced that its headquarters building in Brisbane has been certified under the BREEAM sustainability scheme - the first building in Australia to receive such a certification.

Safety and reliability with AESSEAL heavy duty seal

A mining company in Australia was facing persistent problems from seal failures on one of its slurry pumps.

AESSEAL W.A. launched in key Australian investment

AES Engineering Group Ltd has made another key acquisition in Australia, providing country-wide coverage as part of the Group’s ongoing global growth strategy.

Mining company saves $8 million AUD with AESSEAL system

A coal mine in Australia was having seal failures roughly every two weeks on two disposal pumps.

AESSEAL NSW Pty Ltd launched in key Australian investment

The AES Engineering Group Ltd has announced the launch of AESSEAL NSW, partnering with two leading New South Wales companies, in line with the Group’s ongoing global growth strategy.

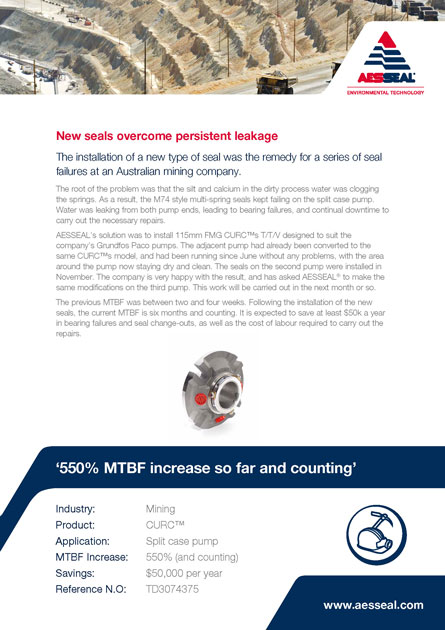

New seals overcome persistent leakage

The installation of a new type of seal was the remedy for a series of seal failures at an Australian mining company.

Reduced maintenance and water consumption at Iron Ore Mine

An iron ore mine in Australia was experiencing unacceptably high maintenance costs on its Warman Thickener Underflow pumps. The pumps were sealed with Gland Packing that was flushed with 48litres per minute.

Replacing Gland Packing Reduced Maintenance

A local municipal swimming pool in Australia was using gland packing on the main pool pump.

Training and support leads to reliability

Ongoing reliability issues with their pulp agitator mechanical seals led Australian pulp and paper manufacturer to turn to AESSEAL® for assistance.

Huge cost savings and improved reliability with gland packing upgrade

A mean time between failure (MTBF) of just 2 months meant that costs at over $135,000 AUD for pump maintenance were unacceptably high.