AESSEAL plc

Unit 2 Knowles Street,

Venlo Industrial Estate,

Bradford

BD4 6HA

United Kingdom

Related News For This Country

Inspiring Future Innovators at Get Up to Speed 2025

For the eighth consecutive year, AESSEAL proudly sponsored the Get Up to Speed with STEM (GUTS) 2025 event as a Gold Sponsor, reinforcing our dedication to nurturing the next generation of engineers, problem-solvers, and industry leaders.

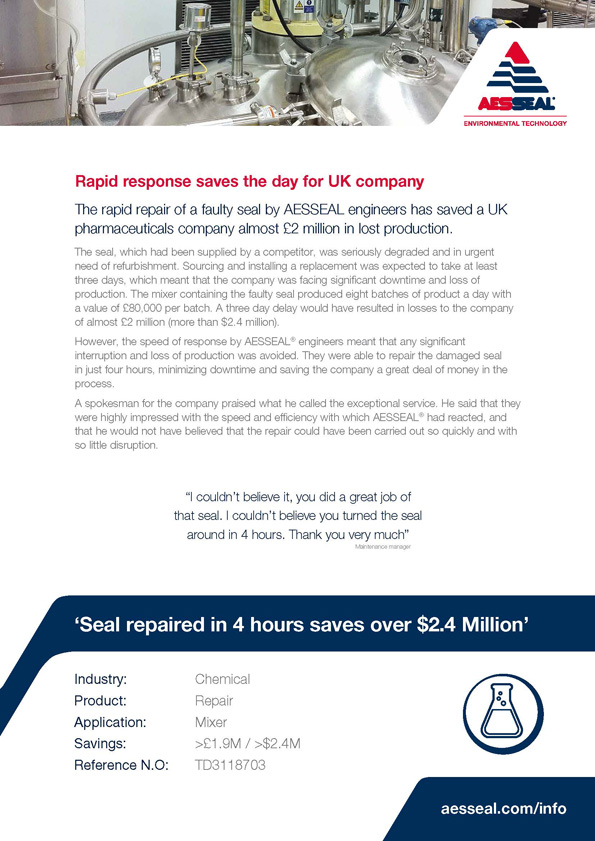

Rapid response saves the day for UK company

The rapid repair of a faulty seal saved a UK pharmaceuticals company almost £2 million in lost production.

Factory for the Future Shortlisted for RIBA Yorkshire Awards 2025

AESSEAL is proud to announce that its Factory for the Future has been shortlisted for the prestigious RIBA Yorkshire Awards 2025. This recognition highlights the company’s commitment to innovation, sustainability and excellence in architectural design.

Strengthening Supply Chain Resilience

Christian Pulman, Head of Procurement, AESSEAL plc, is driving data-led strategies to optimise inventory and adapt to global challenges, ensuring seamless operations and regulatory compliance.

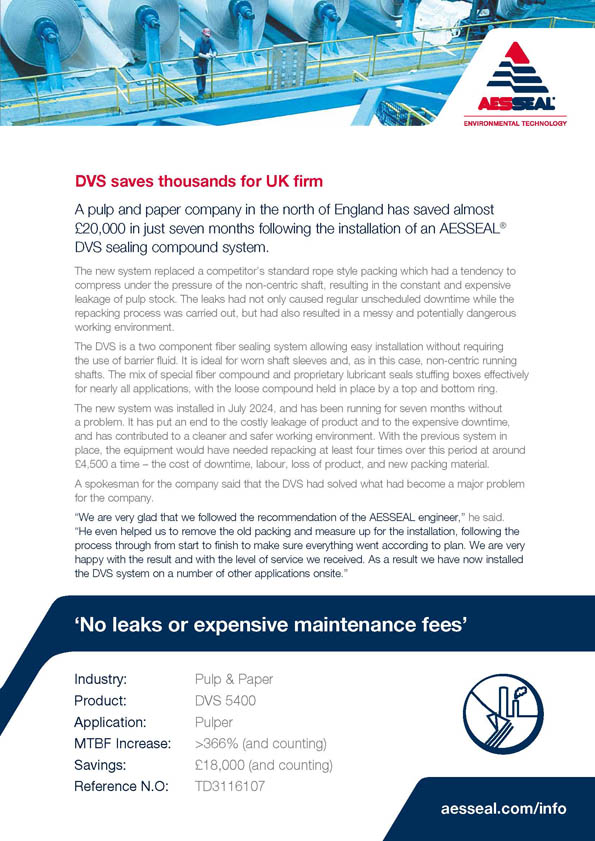

DVS saves thousands for UK firm

A pulp and paper company in the north of England has saved almost £20,000 in just seven months following the installation of an AESSEAL® DVS sealing compound system.

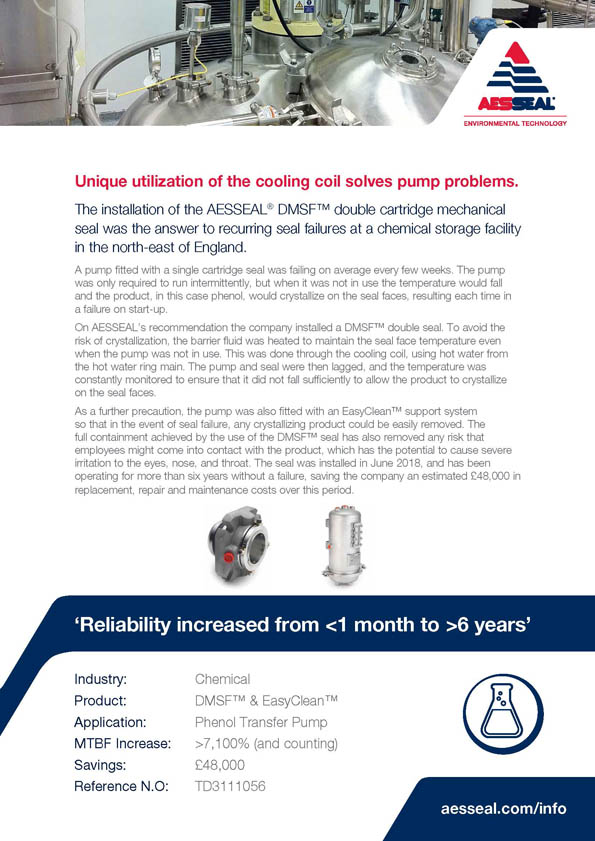

Unique utilization of the cooling coil solves pump problems.

The installation of the AESSEAL DMSF double cartridge mechanical seal was the answer to recurring seal failures at a chemical storage facility in the north-east of England.

CAPI-TXS the answer for legacy quench oil pumps

The single seals on three BB2 hot quench oil pumps at a petrochemical plant in the north of England were regularly failing due to poor face lubrication by the product. In addition, contamination of the bearing oil from the seal steam quench was leading to repeated bearing failures.

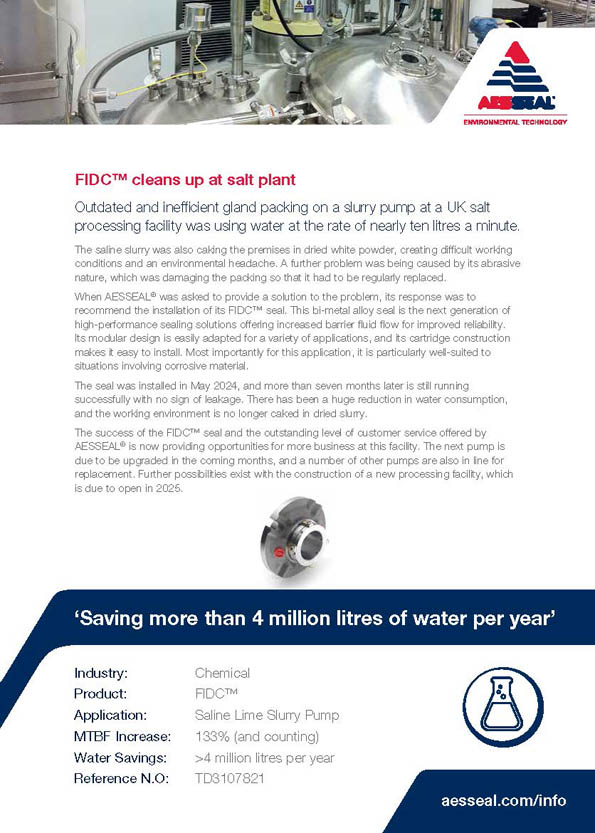

FIDC cleans up at salt plant

Outdated and inefficient gland packing on a slurry pump at a UK salt processing facility was using water at the rate of nearly ten litres a minute.

Chris Rea – Graduate of the Year!

Chris Rea has been honoured as Allstate NI Queen’s Graduate of the Year 2024 at Queen’s University Belfast’s annual Charter Day Dinner.

AES: Economic Innovator of the Year

AES Engineering Ltd has been selected as the UK North East region’s Economic Innovator of the Year in the annual awards run by The Spectator magazine.

Staying cool in Cardiff

The cooling system in a High Profile office building in the Cardiff Bay area was operating with just a single duty pump and no standby.

Inspiring Future Engineers at North Star Science School

On Wednesday, 20th November 2024, North Star STEAM workshops welcomed over 500 young people to Gulliver’s Valley in Rotherham, sponsored by AESSEAL for the fifth consecutive year.