- Home

- Locations

- North America

- Canada

Canada

Unlock your potential with AESSEAL®

Related News For This Country

AESSEAL cools the temperature at Canadian paper mill

The installation of an AESSEAL SMSS single cartridge seal has saved thousands of dollars in repair and replacement costs for a Canadian paper mill.

Fantastic seal life for notoriously difficult application

A pulp & paper company in the Canada were dissatisfied with the reliability of the mechanical seal used in its Chlorine Dioxide generator pump.

AES Engineering global expansion continues with acquisition of Vibtech Analysis in Canada

AES Engineering Group has increased its reliability services and product offering in Eastern Canada with the acquisition of Vibtech Analysis Ltd.

Improved reliability for new process

A refinery in Canada were commissioning a new lipids coprocessing initiative where renewable feedstock is injected into the cracker.

Reliability upgrade reduces water consumption

Kraft pulp mills with recovery boilers have multiple effect evaporators and concentrators to reheat and remove water from the returning Weak Black Liquor from the cooking process.

AES Engineering strengthens the Canadian market with acquisition of PCS Sealing, Edmonton, Canada

A Performance Compression and Sealing Company, which specialises in fluid sealing products & services, has sold a controlling stake to AES Engineering Ltd.

Sealing Solutions for Pulp and Paper Series

AESSEAL invites you to attend our 2022 series of informational webinars covering different aspects of sealing rotating equipment in the pulp and paper industry.

Eliminating over 61 million gallons of water from 26 evaporator pumps

Evaporator steam use reduced by 103,000klbs a year by eliminating over 61 million gallons of water from 26 evaporator pumps

Reliability problems solved at mill

A Canadian paper mill was having issues with the reliability of its Chlorine Dioxide Generator Circulation Pump.

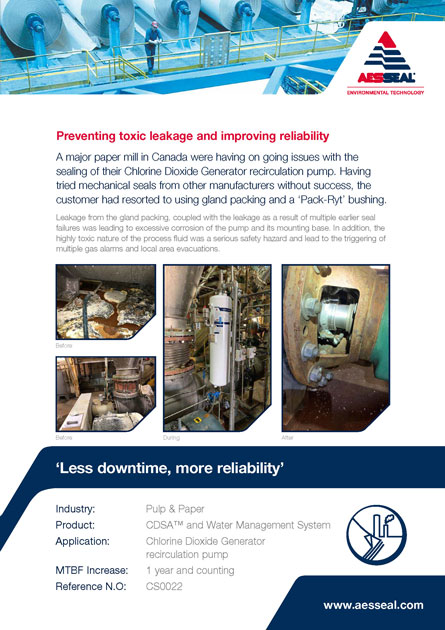

Preventing toxic leakage and improving reliability

Having tried mechanical seals from other manufacturers without success, the customer had resorted to using gland packing and a ‘Pack-Ryt’ bushing for their Chlorine Dioxide Generator recirculation pump.

AES Engineering Ltd’s global reach strengthened by acquisition of JAtech Services Canada

Leading Canadian asset condition monitoring specialist JAtech Services has become part of the AVT Reliability Group following its acquisition by Rotherham-based AES Engineering Ltd.

Seal upgrade improves reliability and simplifies maintenance

A major integrated zinc / lead smelter company in Canada was unhappy with the performance of the existing mechanical seal.