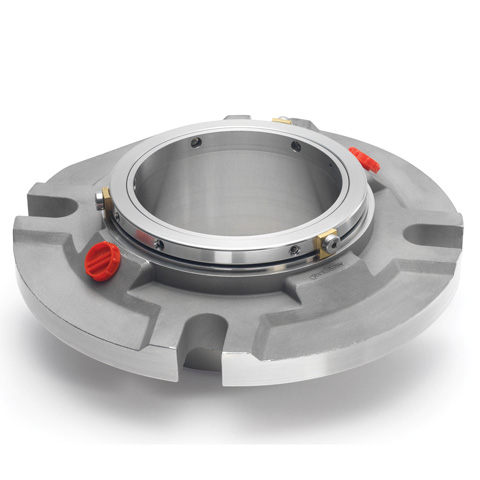

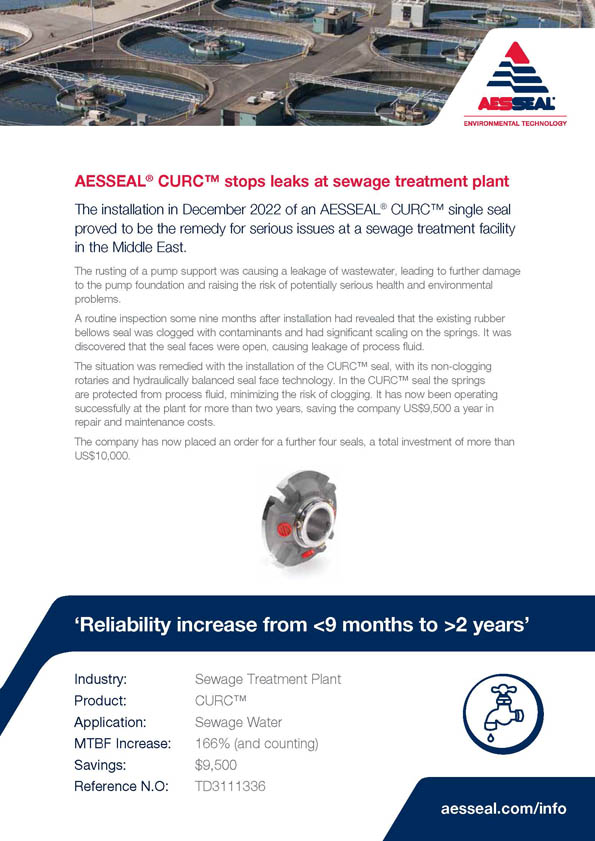

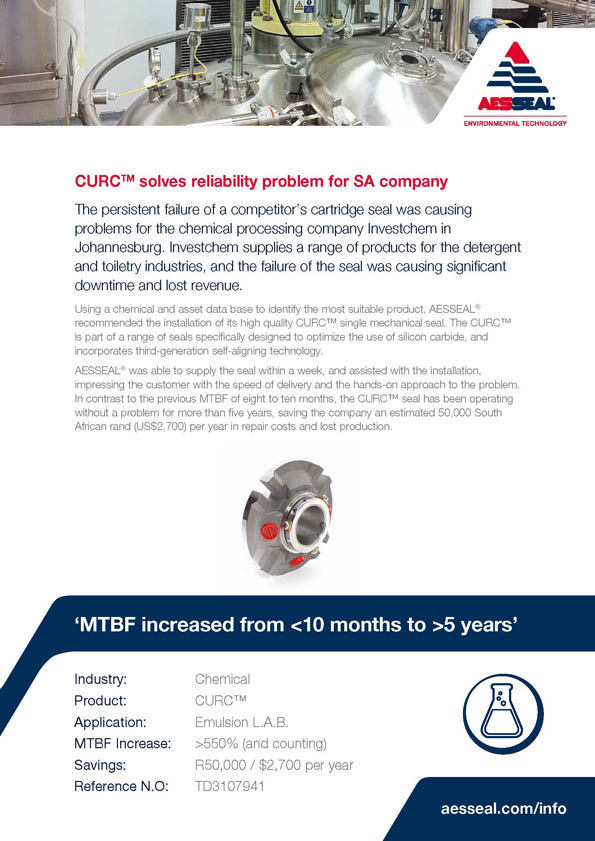

The AESSEAL CURC™, CRCO™ and CURE™ mechanical seals are part of a range of seals specifically designed to optimize the use of Silicon Carbide.

All these seals incorporate improved third generation self aligning technology. The design objective was to minimize metal to Silicon Carbide impact, particularly on start–up.

In some seal designs, impact between metal anti–rotation pins and Silicon Carbide can be sufficiently severe to induce stress cracking in the Silicon Carbide. Silicon Carbide has many advantages when used in mechanical seals. The material has superior chemical resistance, hardness and heat dissipation properties compared to practically any other material used as a mechanical seal face. Silicon Carbide is, however, brittle by nature, so the design of the self–aligning stationary in the CURC™ range of mechanical seals seeks to minimize this metal to Silicon impact on start–up.

ATEX Range Certifications

- CURC

- Category 2 (Zone 1/21) & Category 3 (Zone 2/22)

Features:

- Self Aligning stationary face, maximizing seal life

- Stationary face with radial locating pins minimizes damage in stop / start applications with viscous fluids

- Quench flush and drain ports for cooling or heating options to maximize seal life

- CRCO™ lip seal option

- CURE™ secondary seal option

- ANSI+ gland options

- Bi-Metal option with exotic alloy wetted components for maximum versatility at minimum price premium

- Hydraulically balanced seal face technology for reduced power consumption

- Non-clogging rotaries and non shaft fretting elastomers

- Multiple spring and positive set screw shaft drive

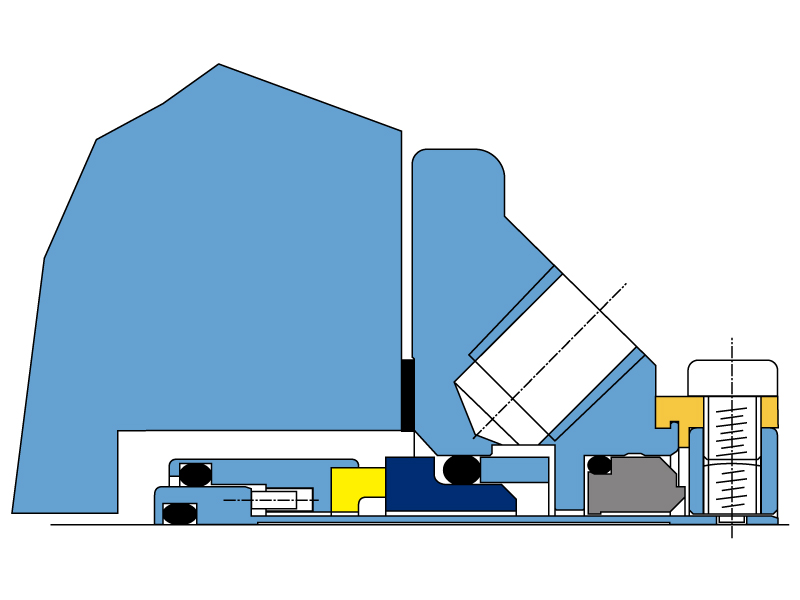

Single Seals with Environmental Control Options

General service applications are efficiently sealed with an ‘O’ ring mounted, balanced, self–aligning seal. The SAI™, CS™, USI™ and NSI™ component seals and the SCUSI™ and Convertor II™ cartridge seals effectively seal all general service applications.

At the other end of the application spectrum, hazardous and dangerous products demand an engineered sealing approach. Double seals with closed–loop convection tank systems provide the necessary back–up protection.

Between these application extremes lie non–lubricating and/or non–hazardous fluids that alter their state with environmental changes. A single seal, with an API type gland, provides temperature control and protection from atmospheric contact for these applications.

Secondary fluids introduced through the Quench and Drain ports to the atmospheric side of the seal faces, control the environment without dilution of the process fluid. Water, steam, grease, oil and other suitable barrier fluids can be used.

Suitable for the following industries