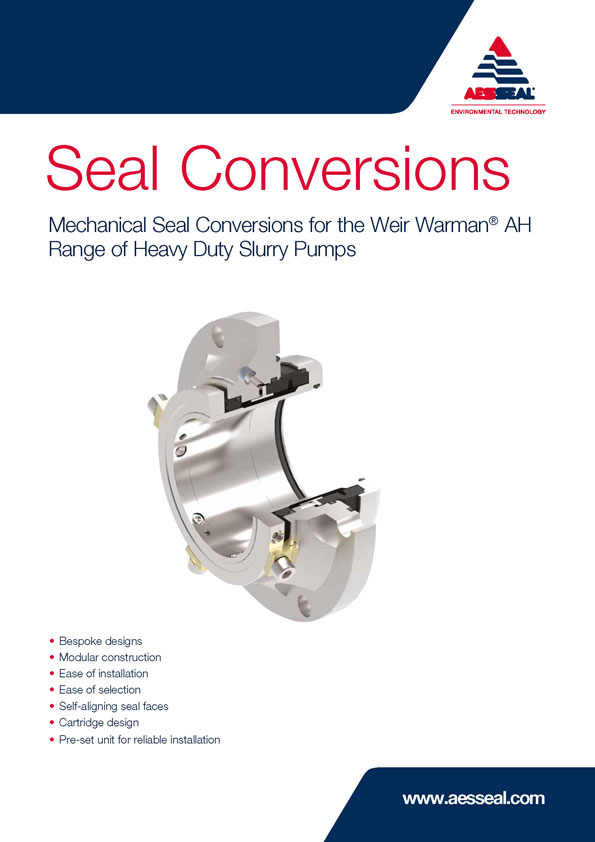

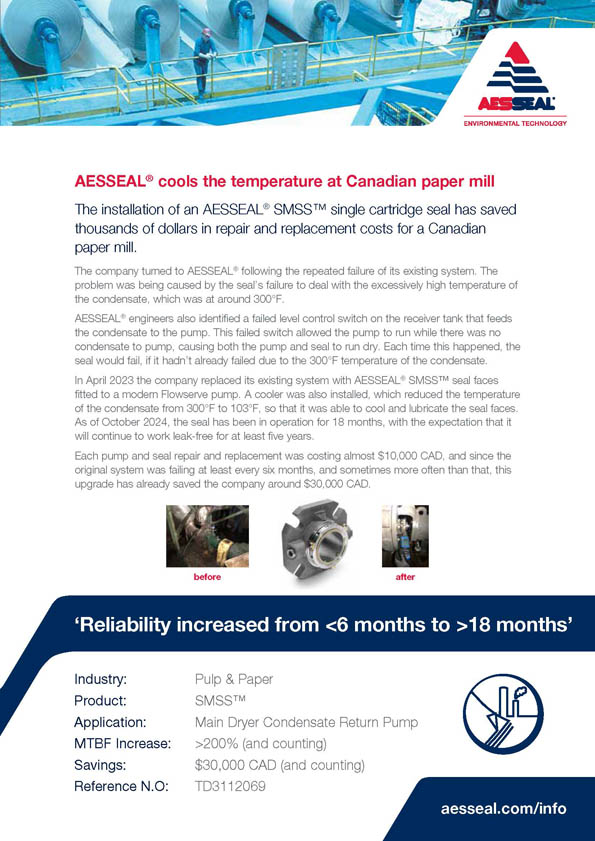

The AESSEAL® range of single cartridge mechanical seals has been specifically designed to eliminate some of the main causes of premature mechanical seal failure.

The small SMSS™ design includes the following features:

a. Monolithic Seal Faces

All seal faces are of monolithic, one piece, construction and therefore are less likely to distort in high and low temperature applications.

b. Seal Face Drive Mechanism

Finite Element Analysis has been used to optimize seal face drive. Precise, solid machined drive lugs reduce drive slop between the drive ring and seal face. This reduces seal face damage on equipment start-up / shut-down.

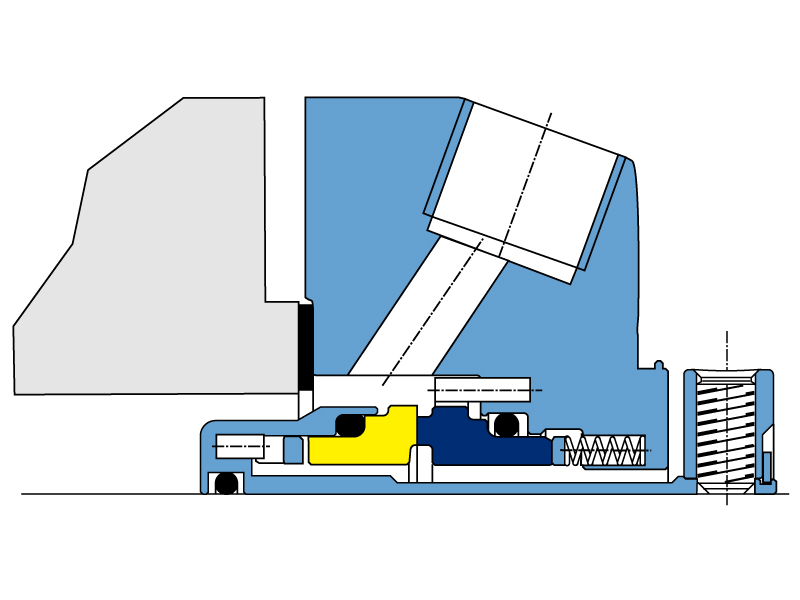

c. Optimized Seal Environment

All environmental control ports are 3/8” NPT, helping to maximize the cooling effect. Two flush ports, positioned directly over the seal faces, provide the option of tangential flushing, irrespective of shaft rotational direction.

d. Optimized Seal Face Loading

The multi-spring design ensures uniform seal face loading. In addition all springs act on metallic components, and therefore cannot damage or chip seal faces.

e. High Shaft Speed Applications

The stationary seal construction helps to minimize spring fatigue for optimum performance on high shaft speed applications.

Suitable for the following industries