Compressor Dry Gas Seals and Systems

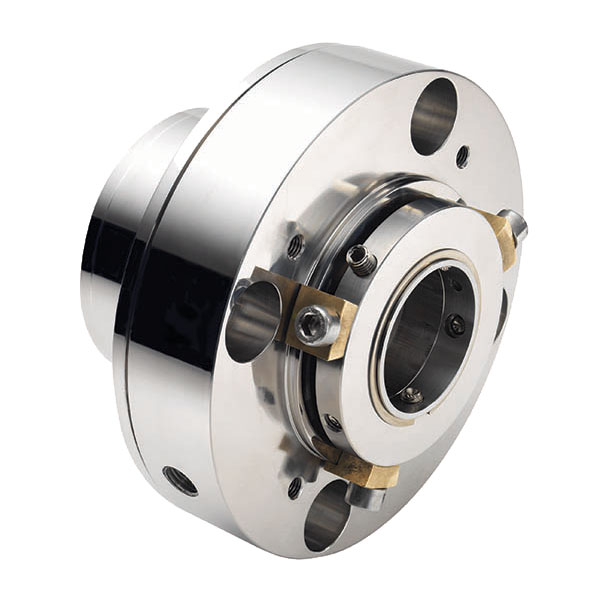

Dry gas seals are considered by many to be at the top of the mechanical seal technology ladder and operate in a different manner to the more common wet mechanical seals. Download our range brochure.

YouTube Video Series

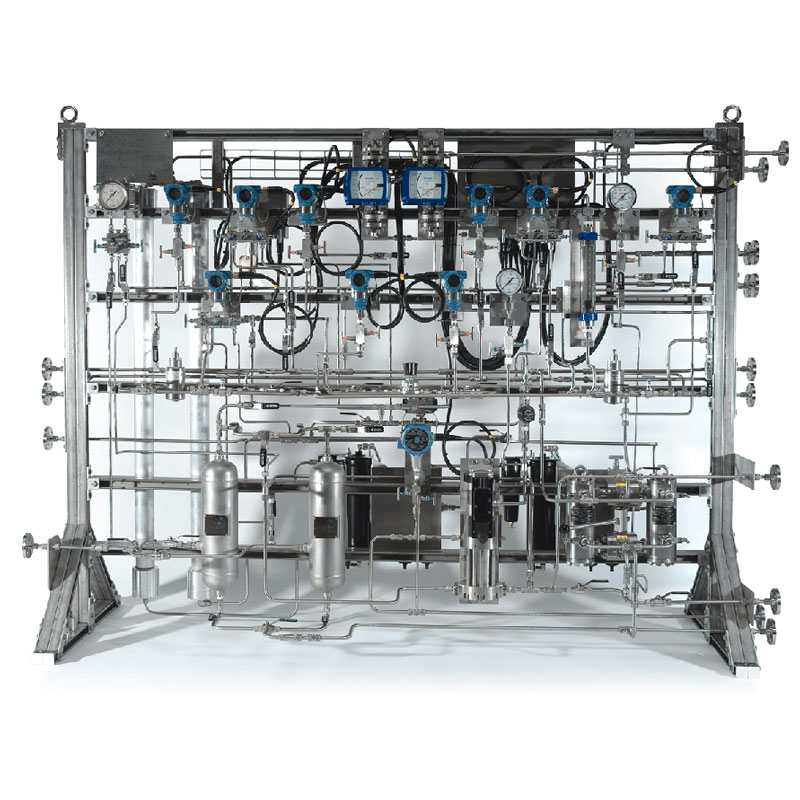

AESSEAL® provides the best environmental technology solutions for your turbomachinery assets.

Our dry gas seal repair program supports all of our customers, regardless of the original equipment manufacturer. We will show you around our world class facility, giving an insight in to how we build, test and repair dry gas seals. We are a superior quality manufacturer focusing on quality and exceptional customer service.