AESSEAL® has unique, patented hydrostatic and hydrodynamic Dry Gas Compressor seal technology, offering robust protection for the sealing surfaces during start-up, shutdown, slow roll, and upset conditions.

The HHCS™ is a tandem cartridge seal where the inboard seal is designed to seal up to 150 bar (2175 psi) and an outboard seal that acts as a low-pressure tandem seal. The outboard seal is capable of full pressure containment in the event of full seal failure.

The tandem arrangement can be supplied with intermediary labyrinth for inert gas buffer duty. Single and dual seal options also available.

Features:

- Unique patented hydrostatic and hydrodynamic Dry Gas Compressor seal technology offers robust protection for the sealing surfaces during start-up coastdown slow roll and upset conditions

- Increased hydrostatic lift for early face separation at much lower pressure differential than conventional seals

- Supplied in 410 stainless steel as standard with exotic alloy options on request

- Dynamic leakage considerably lower than comparable conventional spiral groove seals

- Available with Silicon Carbide seats as standard. Silicon Nitride seats available on request. Mating faces available in Carbon and synthetic diamond-coated Silicon Carbide

- Capable of withstanding unintentional reverse rotation

- ‘O’ ring and spring energized polymer versions available

- Designs available in tandem or tandem with intermediate labyrinth for increased integrity

- Fully shrouded seats adopted as standard

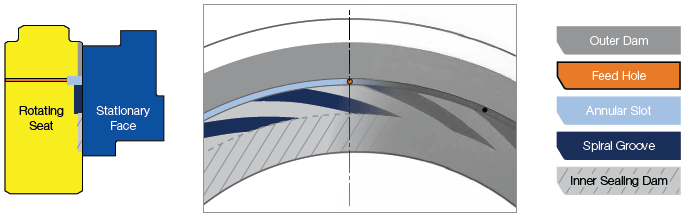

DualDam Technology

Our patented DualDam™ technology provides a more stable gas fluid film in all phases of operation to ensure a more reliable seal.

The DualDam™ gas intensifying design comprises 5 elements which combine to provide an optimum sealing interface. The design specifically addresses the period of transition between static and dynamic operation. This is the period where many dry gas seals are generally considered to be most vulnerable to a breakdown in the sealing interface. The 5 elements are described below.

During the static condition, the outer sealing dam acts in conjunction with the feed holes and annular slot to provide controlled pressure decay. This allows for a pressure balance to be achieved providing a small opening force on the seal face. This opening force is known as the hydrostatic lift component of the separation mechanism. When conventional equipment is started there is a brief period where the seal faces will contact before sufficient hydrodynamic lift force is generated to separate the faces. Hydrostatic lift technology helps to eliminate this contact reducing the risk of seal failure.

Related Products Pages

Suitable for the following industries