Reduce process steam loss, improve turbine efficiency.

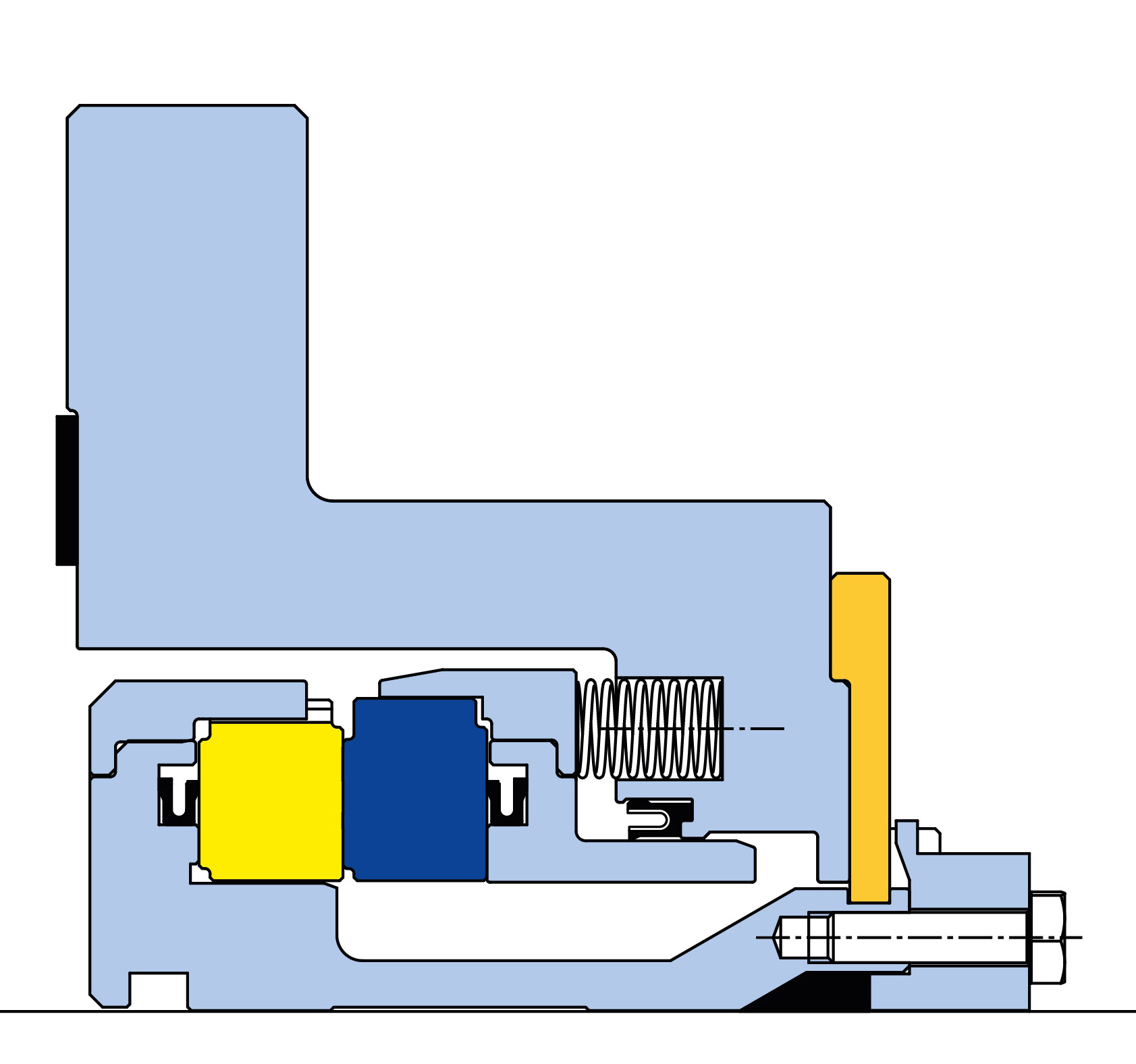

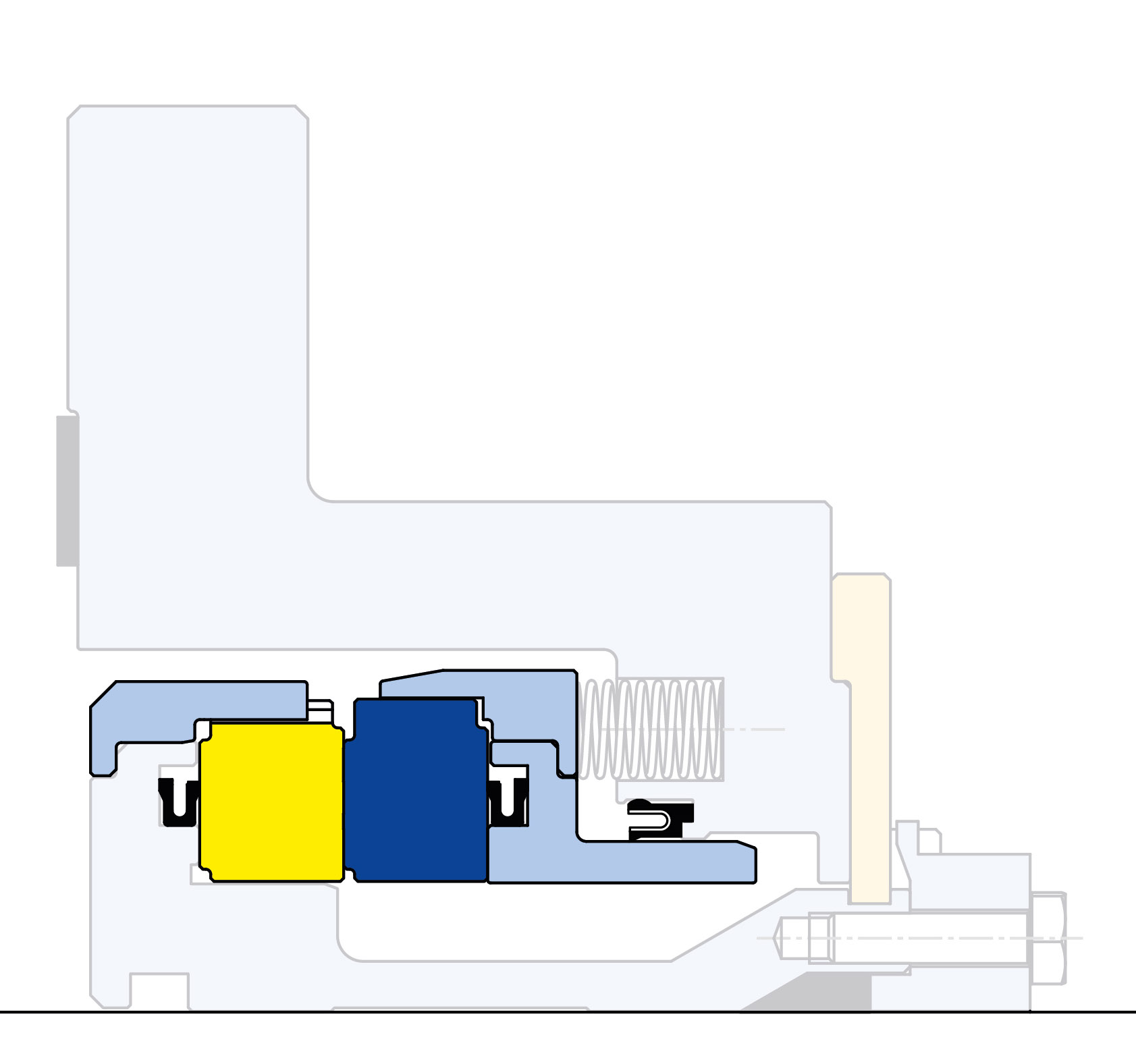

The STS™ mechanical seal has been developed in conjunction with a major oil refinery to replace existing carbon ring seals normally fitted to steam turbines. STS™ adopts AESSEAL® dry running gas compressor seal technology to provide a solution that significantly reduces the steam leakage typically associated with standard carbon ring seals.

Typical Benefits of Steam Turbine Mechanical Seal Technology

- Increased turbine reliability

- Reduced turbine maintenance costs

- Reduced bearing contamination

- Non-contacting technology extends life of seal

- Elimination of Shaft Wear – generated by the Carbon seal

- Greatly reduces steam loss and increases efficiency

Market-leading delivery performance from inventoried standard core modular components.

Rapid CNC manufacture

The adaptive hardware (sleeve and gland plates) can be rapidly CNC manufactured to suit specific machines.

Common equipment specific standard designs which are readily available are listed in this table:

All trademarks, trade names, brand names mentioned or used are the property of their respective owners.

| Manufacturer | Model |

|---|---|

| Elliott | 2BYR -H |

| Elliott | AYR, BYR |

| Coppus / Dresser / Siemens | RL20, TF20, RL16, TF16, |

| Coppus / Dresser / Siemens | RL12, RLA12, RLV12, TF12, TF9 |

| Elliott | 2CYR |

| Terry / Dresser / Seimens /Hayward Tyler | (Z Line) Z2, ZS1, ZSA-1 18 &24 |

| Elliott | 2DYR |

| Coppus / Dresser / Siemens | RLHA 19 |

| Worthington / Dresser / Siemens | 503 703 |

| Coppus / Dresser / Siemens | RLH 24, 28 |

| NG Metlurgica | DSE 550 |

| Coppus / Dresser / Siemens | RLV 16 |

| Terry / Dresser / Siemens | (G Line) GNAT GSA |

| Hayward Tyler | T400 TS600 |

| KKK | BF4 |

| KKK | BF3 |

| Hayward Tyler | T100 TS200 |

| Terry Hayward Tyler | ES |

| Hayward Tyler | S28 |

| Hayward Tyler | S23 |

| Hayward Tyler | TC 24 |

| Weir | GPS HDD1 18 3 |

| Hayward Tyler | TC 25 |

Suitable for the following industries