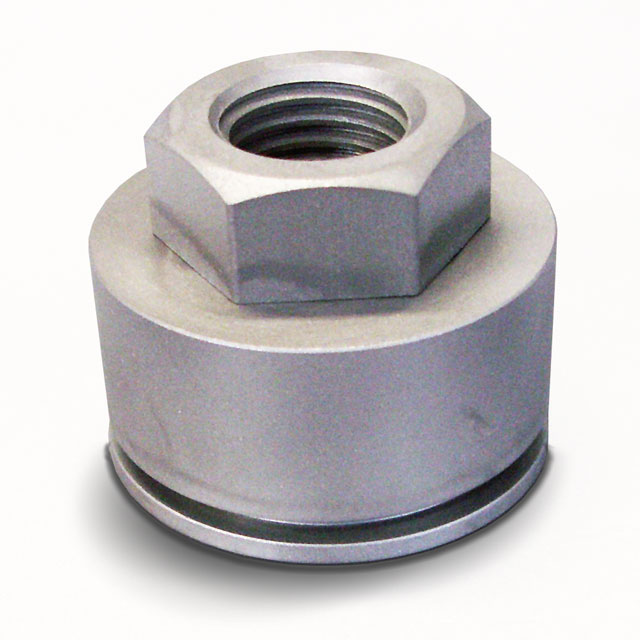

The LiveStar 'Live loading system' screws on top of the bolt in a kind of cup form and giving thereby plenty of extra length to accommodate the uncompressed disc spring stack. This incorporates also an equal load of compression for thermal expansion of the valve. The springs cannot be over compressed as the optimum compression length is set by the LiveStar housing dimension.

A side effect of the system is that the disc springs slide instead on a thread on a smooth machined surface. Further they are encapsulated and protected against dirt and environmental impact.

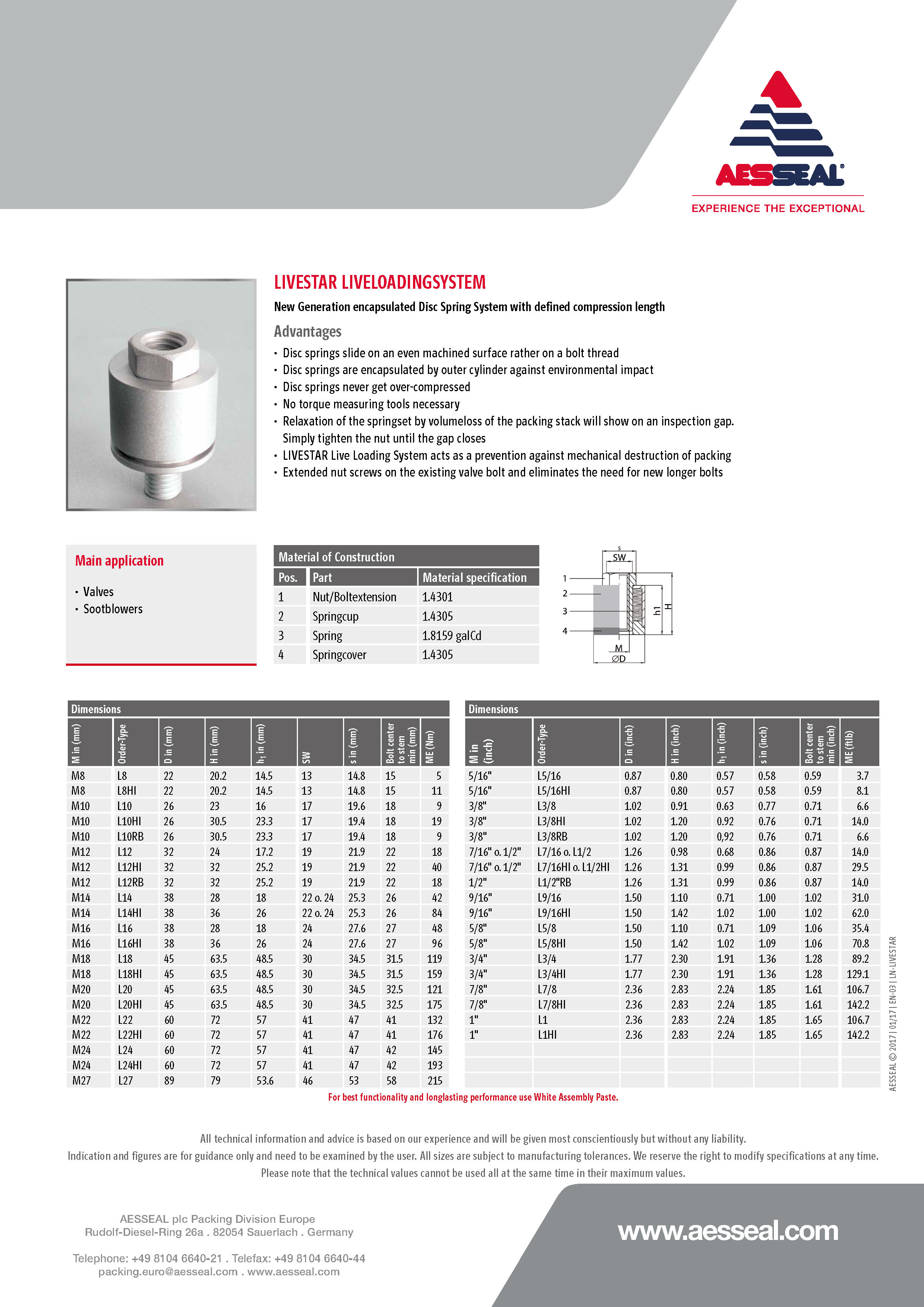

- Disc springs slide on an even machined surface rather on a bolt thread

- Disc springs are encapsulated by outer cylinder against environmental impact

- Disc springs never get over-compressed

- No torque measuring tools necessary

- Relaxation of the springset by volumeloss of the packing stack will show on an inspection gap

- Simply tighten the nut until the gap closes

- LiveStar 'Live loading system'acts as a prevention against mechanical destruction of packing

- Extended nut screws on the existing valve bolt and eliminates the need for new longer bolts