Pump packing is used for high shaft speeds. Pump packing contains specially formulated lubricants to aid equipment start up and ensure packing pliability for a longer life.

Style 210

100% Para-Aramid continuous Fiber with PTFE-Blocking Agent and Silicone free dynamic Run In Lubricant

Style 270 - 274

Combination of ePTFE with Graphite & PTFE Fiber Corner Reinforcement

Style 275TP SlurryStar

Combination Braid of ePTFE with incorporated Graphite and Para-Aramid Fiber Corner Reinforcement

Style 285TP PaperStar

MetaAramid fibre with PTFE blocking agent and run-in lubricant.

Style 290

Synthetic fibre with PTFE impregnation & silicon-free dynamic run-in lubricant

Style 299

Polyimid Fiber with PTFE Impregnation & Silicone Run In Lubricant

Style 325

Carbon Staple fiber with special Graphite Impregnation and Paraffin Run-In Lubricant

Style 330

Carbonfiber with special impregnation and Silicone free dynamic Run-In Lubricant

Style 333

Combination braid from carbon reinforced expanded graphite tape & carbon fiber, with run-in lubricant

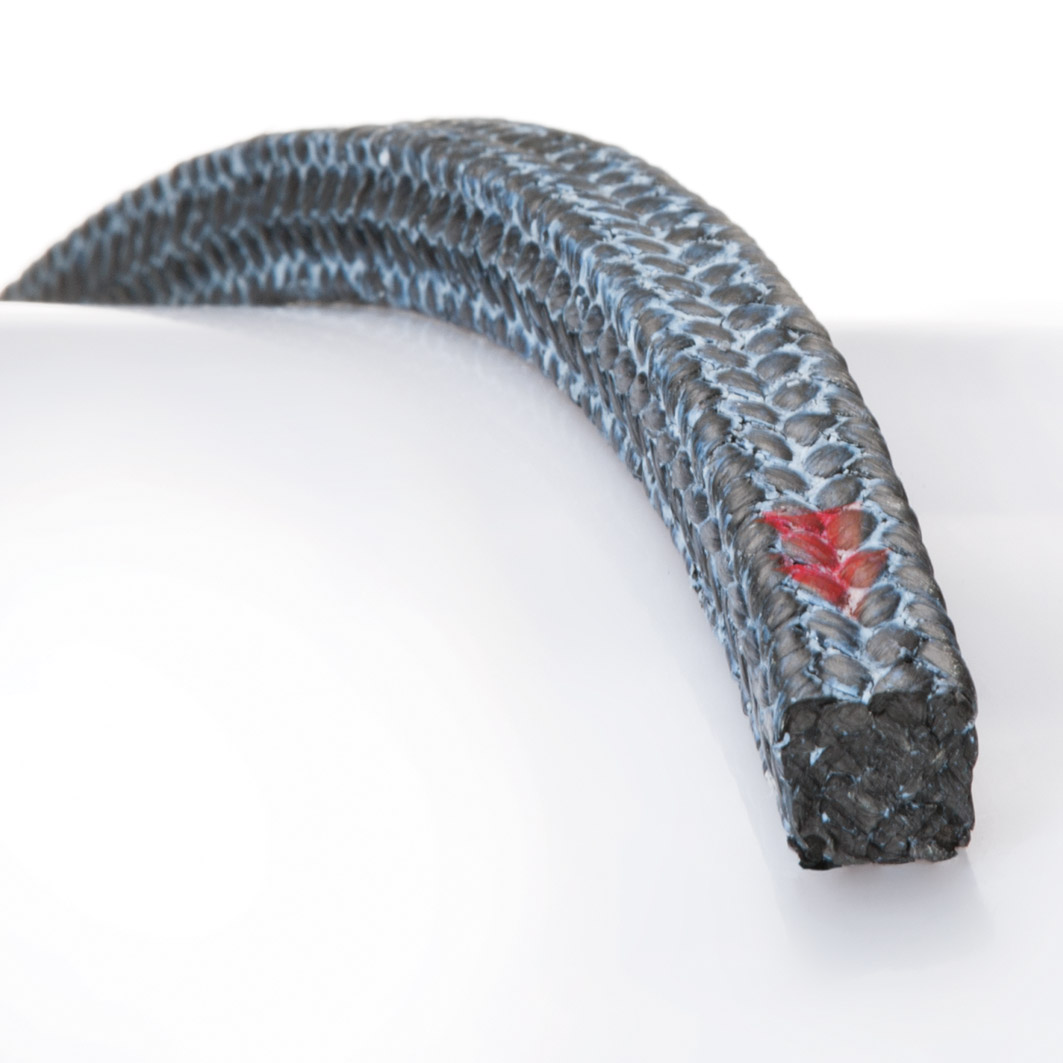

Style 380TP

High puricity carbon-fibre with cross-section impregnation & run-in lubricant

Style 728TP PaperStar HS

Hybrid braid in W-Profile made of heat conductive ePTFE Yarn

Style 785

Braided from 100% GORE® GFO® expanded PTFE fibre with incorporated graphite & silicone run-in lubricant

Style 790

PTFE-Graphite Multifilament Fiber with silicone free ‘run-in’ lubricant

Style 795TP UniStar

Braid of ePTFE yarn with Graphite & Silicone Run-In Lubricant