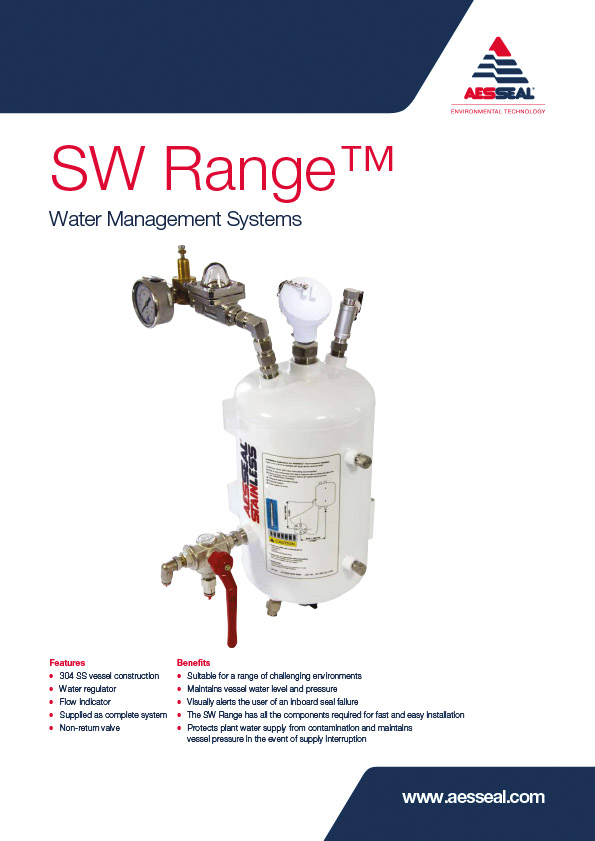

The SW Range consists of the SW2 and SW3 Water Management Systems. The environmentally-friendly SW Range Systems connect directly to the plant water line using it as its fluid and pressure source.

Operating Principle

- Water from the plant water line enters the system.

- The pressure of the barrier fluid in the vessel can be regulated via the pressure regulator.

- The barrier fluid is circulated to the seal and back to the system by the thermosyphon effect.

The plant water line pressure can be adjusted so that the Systems barrier fluid pressure is maintained at 1 bar/15psi above stuffing box pressure. This pressure differential keeps harmful products away from seal faces and increases reliability.

Barrier fluid is circulated to and from the mechanical seal via the thermosyphon effect. This removes water wastage and provides more efficient cooling than once-through quench to drain. The SW3 is supplied with finned tubing as standard so that it can be used on high heat applications.

Features:

- 10 litre / 2.8 gal (US) 304 SS vessel construction - Suitable for a range of challenging environments

- Water Regulator - Maintains water level and pressure in the vessel

- Flow indicator - Visually alerts the user of an inboard seal failure

- Non-return valve - Protects plant water supply from potential contamination and maintains vessel pressure in the event of water-supply interruption

- Available with / without cooling - Additional heat dump available if required

Suitable for the following API Plans

Suitable for the following industries