The API Seal Plans elaborated in this section are as defined by API 682 4th edition / API 610 10th edition.

These are standardized flushing piping arrangements that are widely used in the industry. Customer specific variants of these plans are possible.

API Piping plans help to ensure good conditions for mechanical seal operation as well as improving safety and pump reliability.

Please contact AESSEAL Systems Division for further details. Tel: +44 (0)28 9266 9966 Email: systems@aesseal.com For more information, and a video demonstrating the piping plan in operation, select a plan below

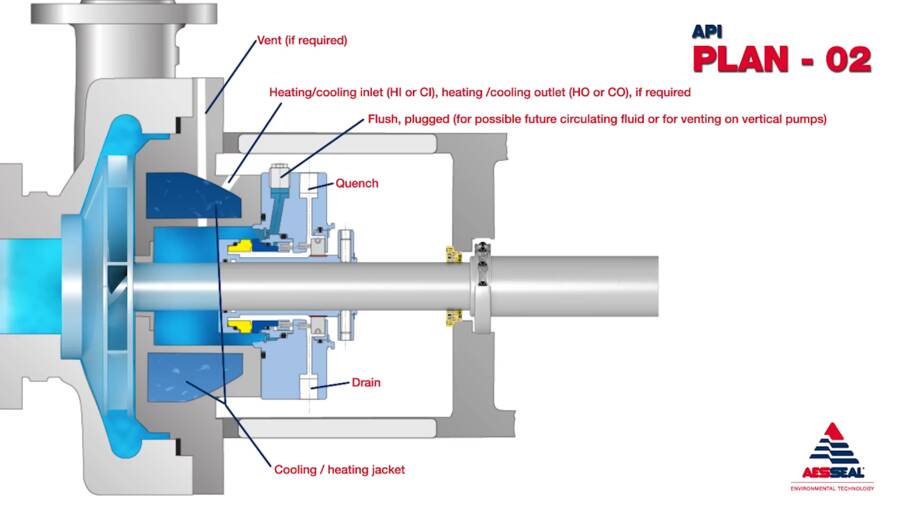

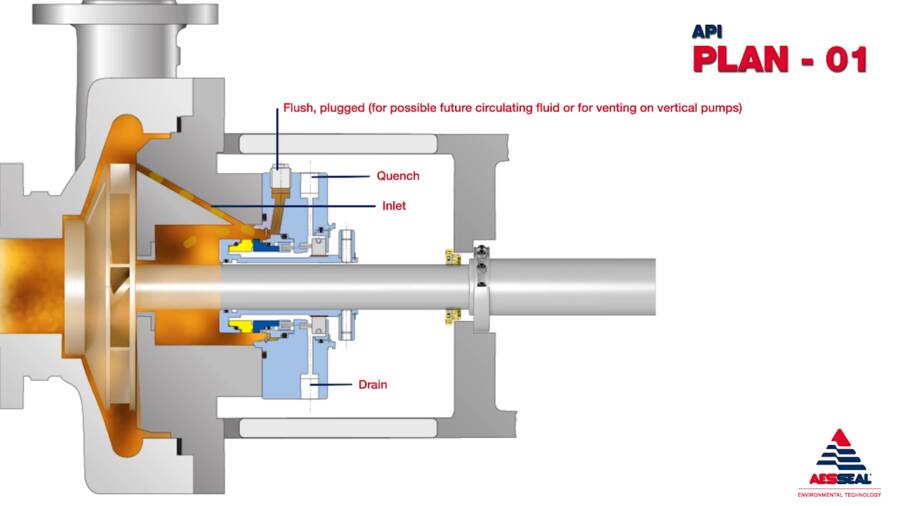

API Plan 01

Integrated (internal) product recirculation from pump discharge to seal chamber.

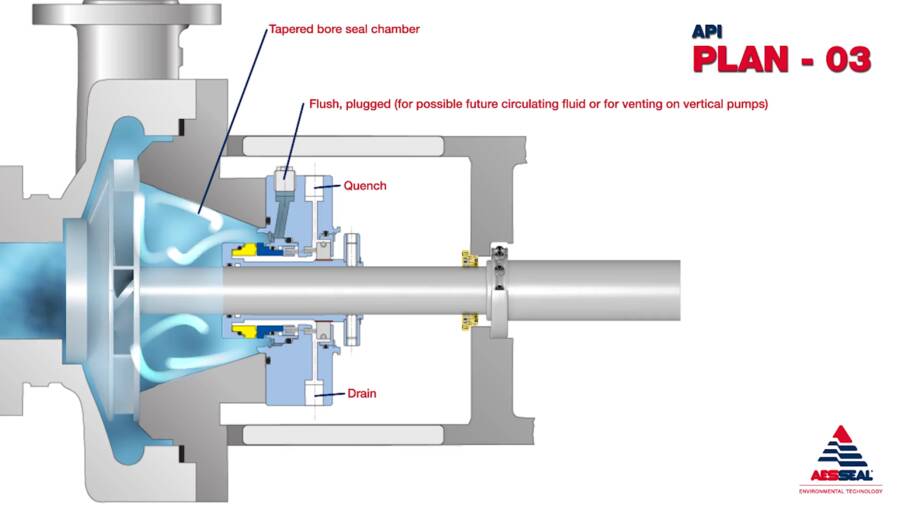

API Plan 03

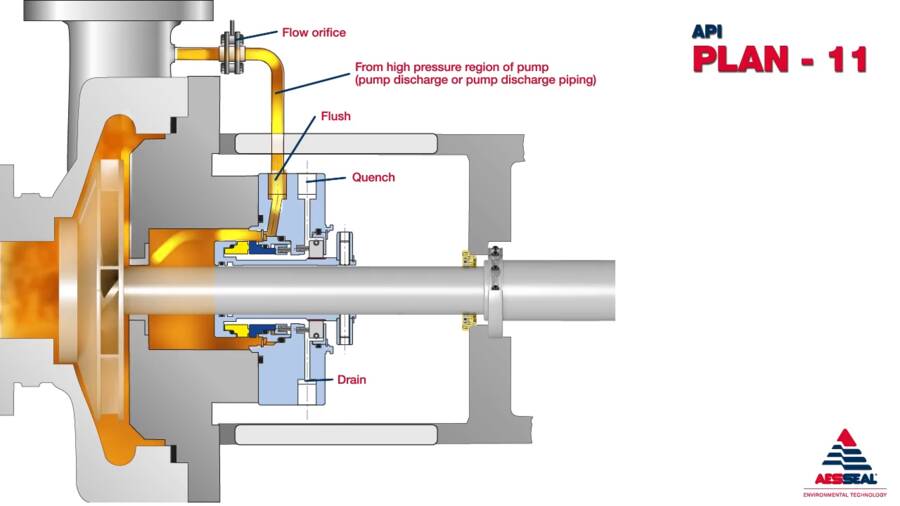

API Plan 11

Product recirculation from pump discharge to seal through a flow control orifice.

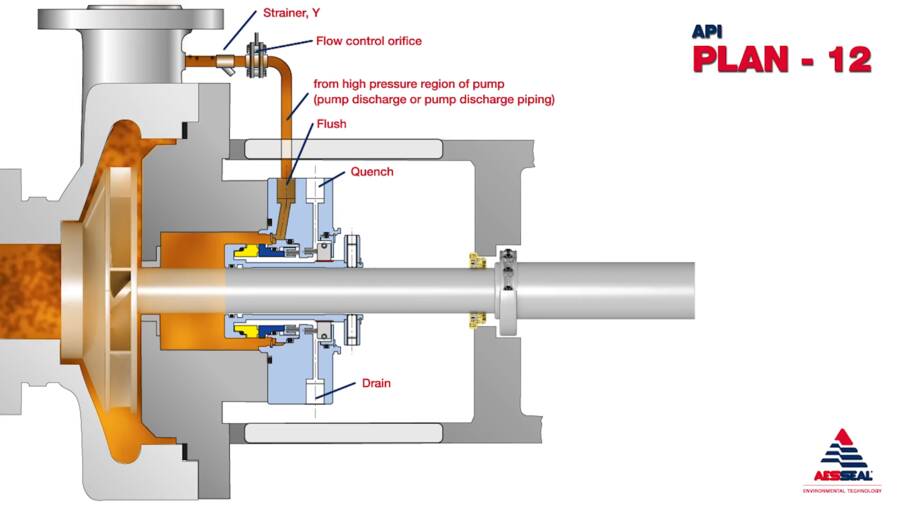

API Plan 12

Product recirculation from pump discharge through a Y strainer and a flow control orifice to seal chamber.

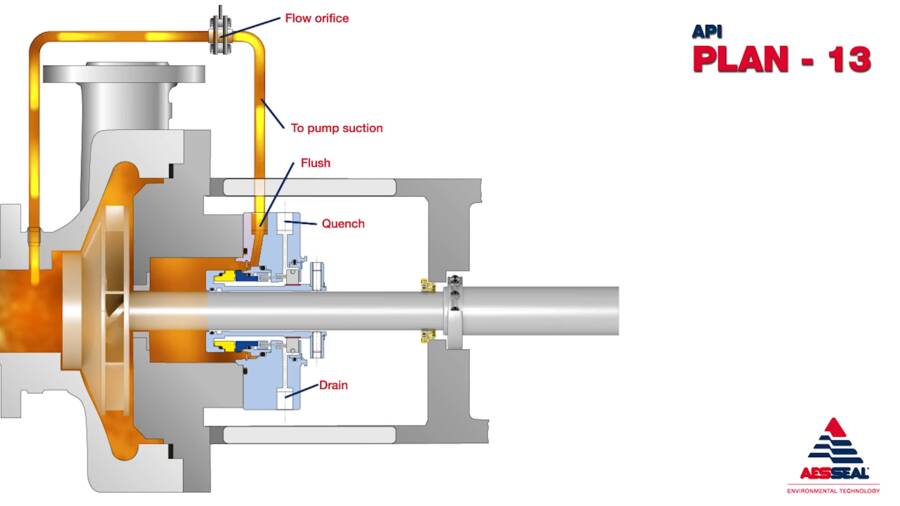

API Plan 13

Product recirculation from seal chamber to pump suction via a flow control orifice.

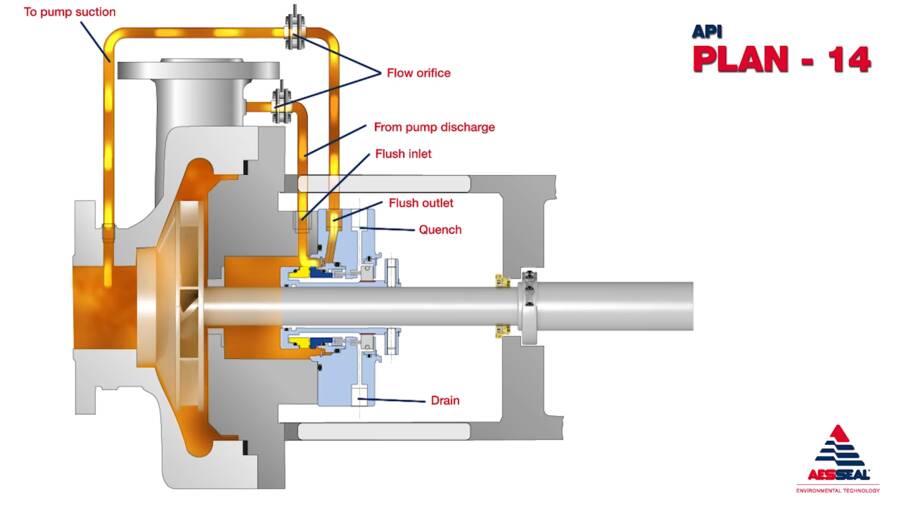

API Plan 14

Product recirculation from pump discharge to seal chamber through a flow control orifice and seal chamber back to suction through another flow control orifice.

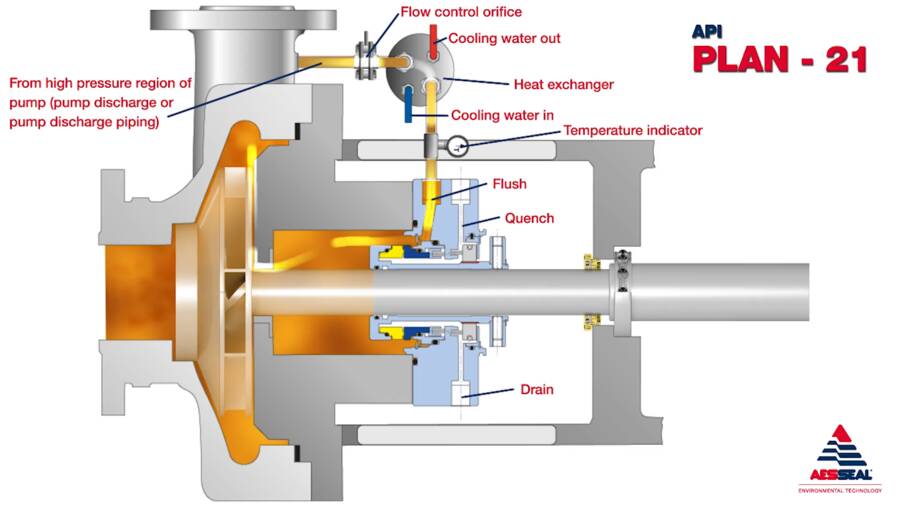

API Plan 21

Product recirculation from discharge through flow control orifice and heat exchanger to seal chamber.

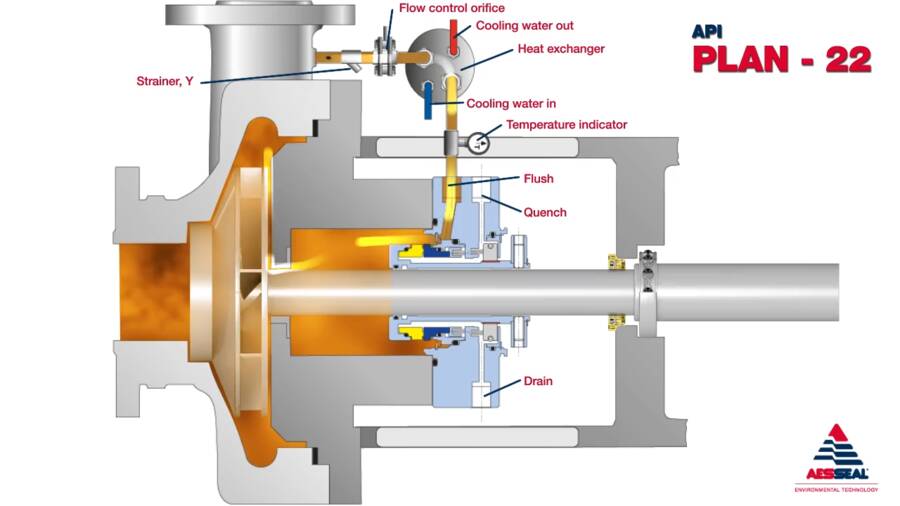

API Plan 22

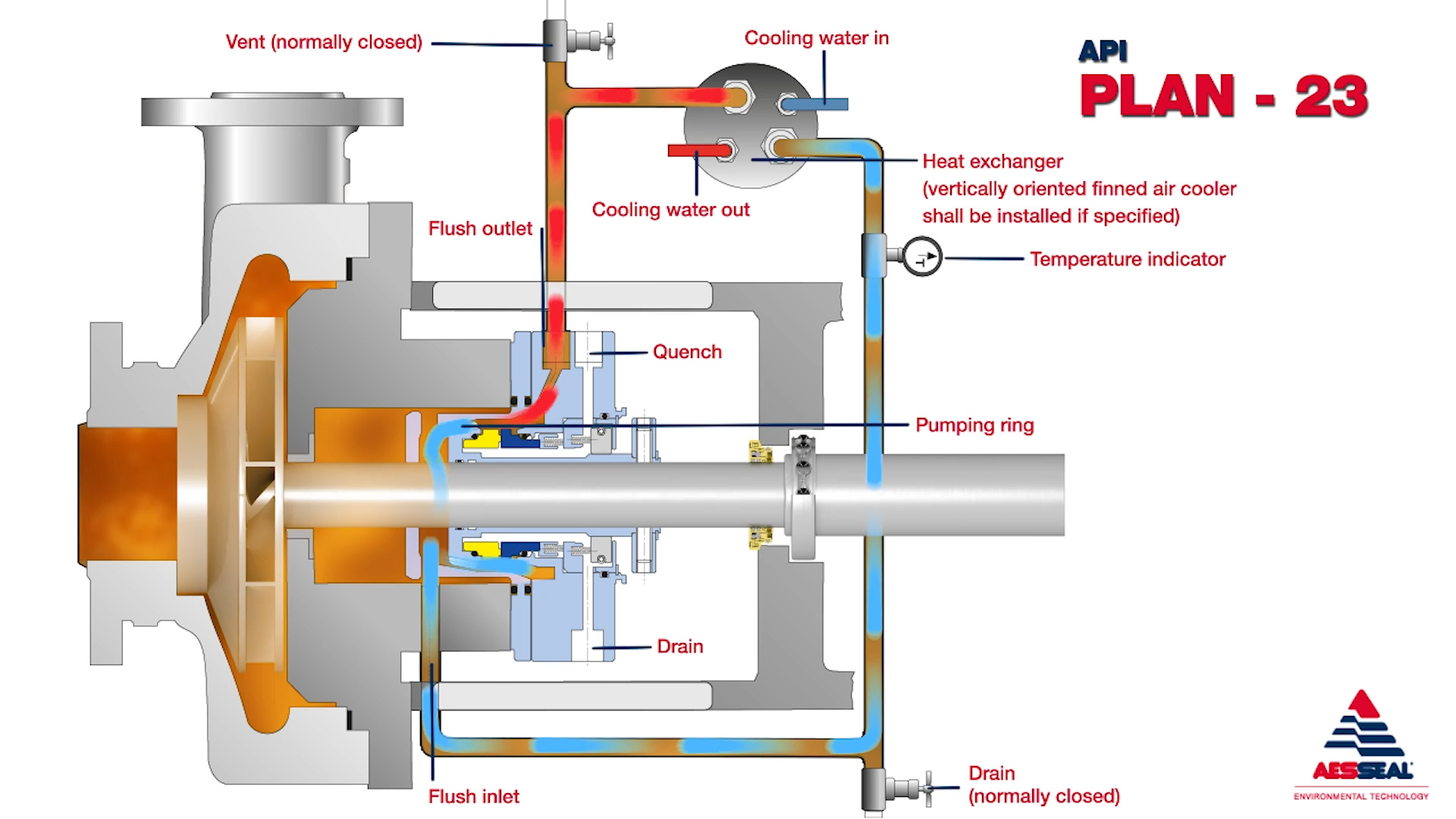

API Plan 23

Product recirculation from seal chamber to heat exchanger and back to seal chamber.

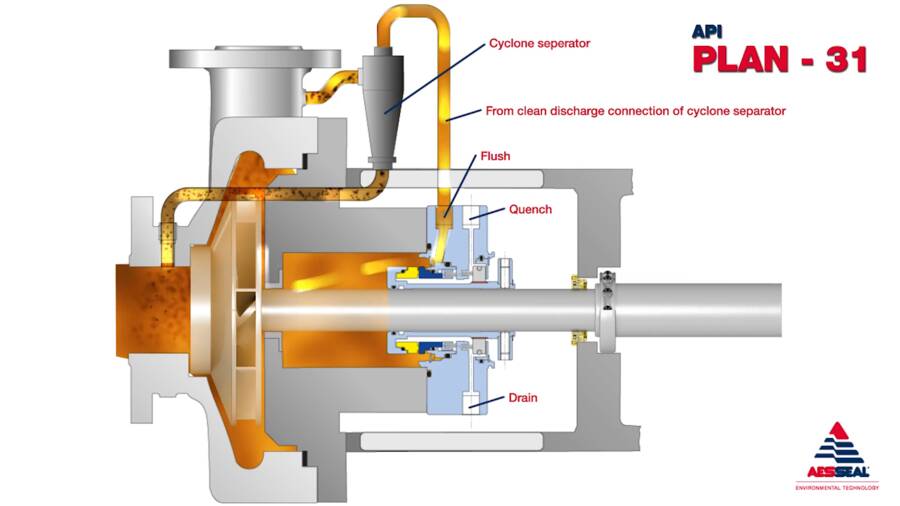

API Plan 31

Product recirculation from discharge through a cyclone separator, which directs clean fluid to the seal and solids back to pump suction.

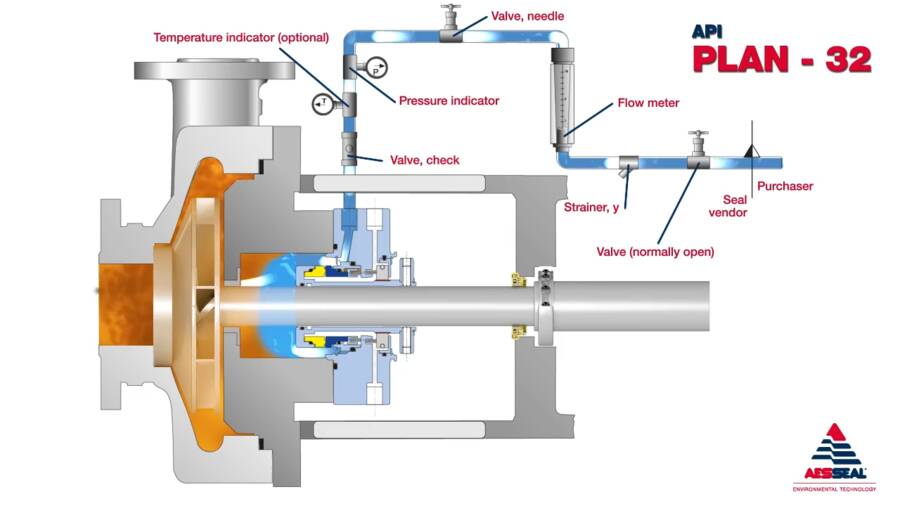

API Plan 32

Injection of clean or cool liquid from external source into the seal chamber.

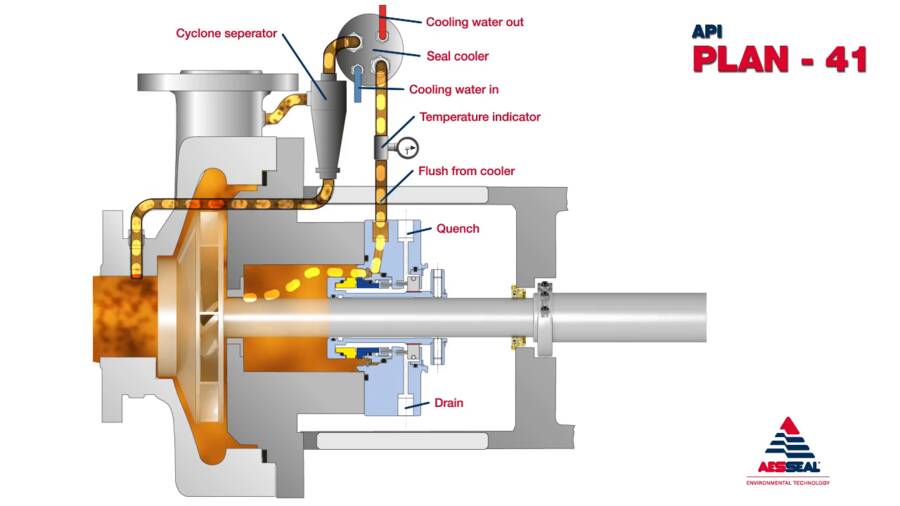

API Plan 41

Product recirculation from discharge through a cyclone separator and a heat exchanger to seal chamber.

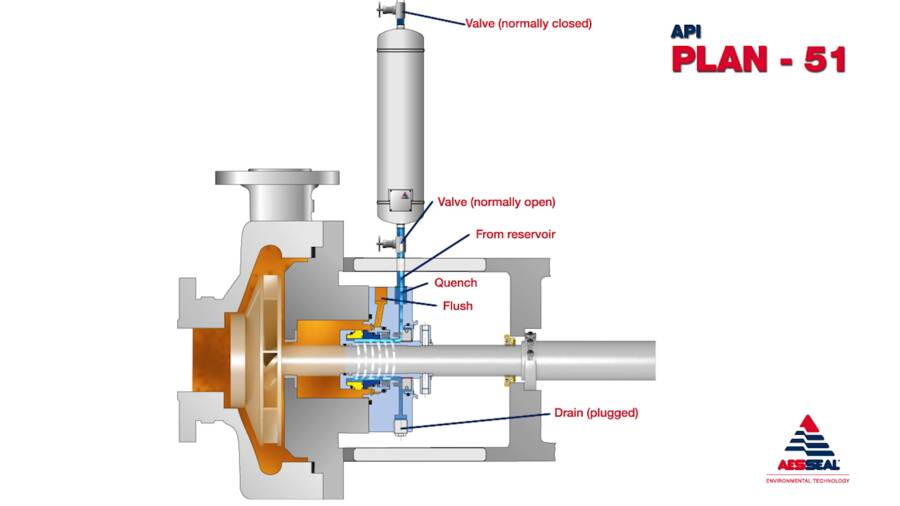

API Plan 51

External reservoir providing a dead-ended blanket for fluid to the quench connection of the gland.

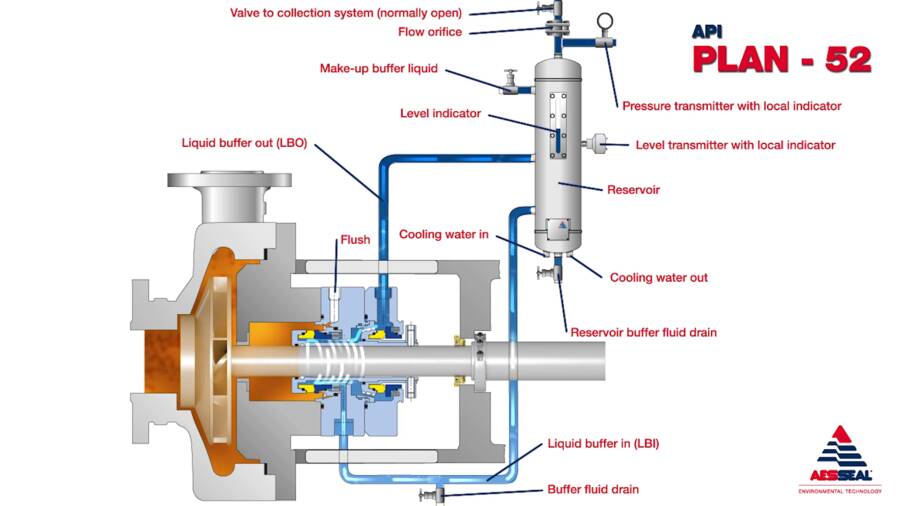

API Plan 52

Depressurised buffer fluid circulation in outboard seal of a dual seal configuration through a seal support system. Circulation is maintained by using pumping ring in running condition and by thermosyphon effect in stand still condition.

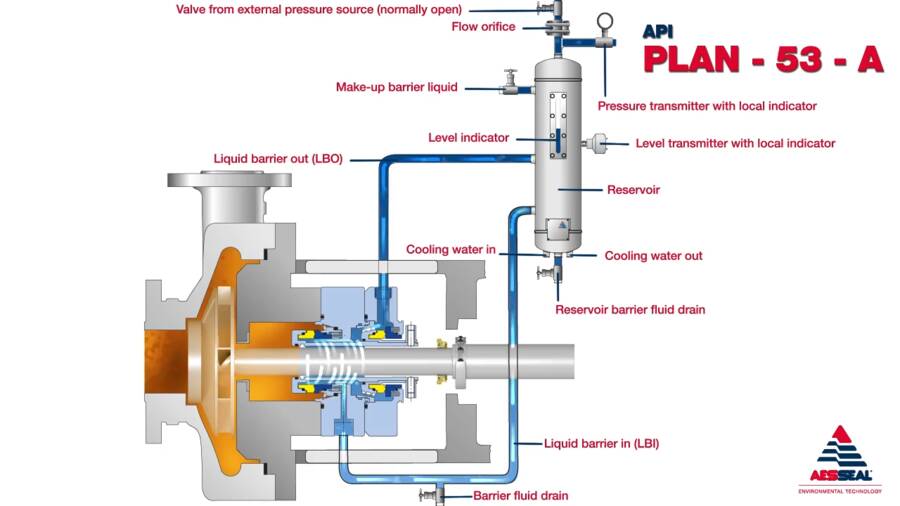

API Plan 53A

Pressurised barrier fluid circulation in outboard seal of dual seal configuration through a seal support system. Circulation is maintained by using pumping ring in running condition and with thermosyphon effect in stand still condition.

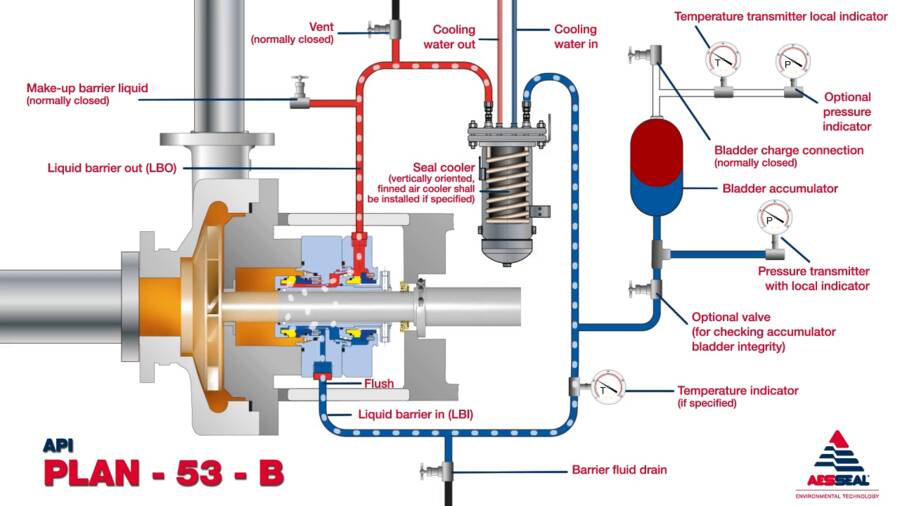

API Plan 53B

Plan 53B systems have been viewed as an engineering challenge around the world, often with long lead times. The innovative modular concept permits 12 modular options to be applied to create an API 53B System for any application.

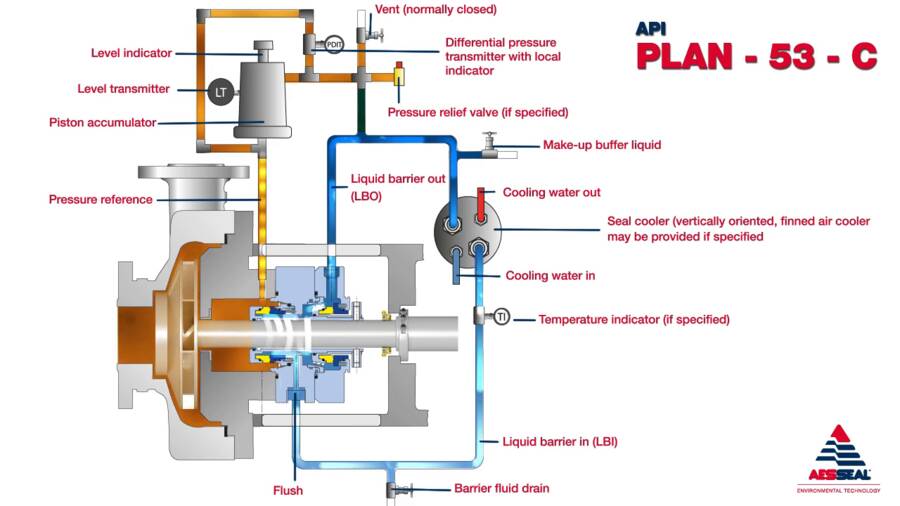

API Plan 53C

Pressurised barrier fluid circulation in outboard seal of dual seal configuration. Circulation is maintained by using pumping ring in running condition and with thermosyphon effect in stand still condition.

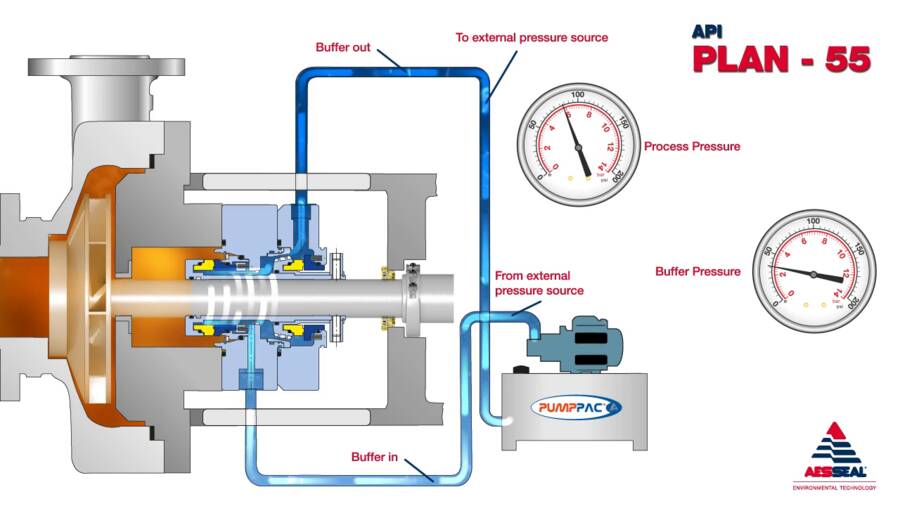

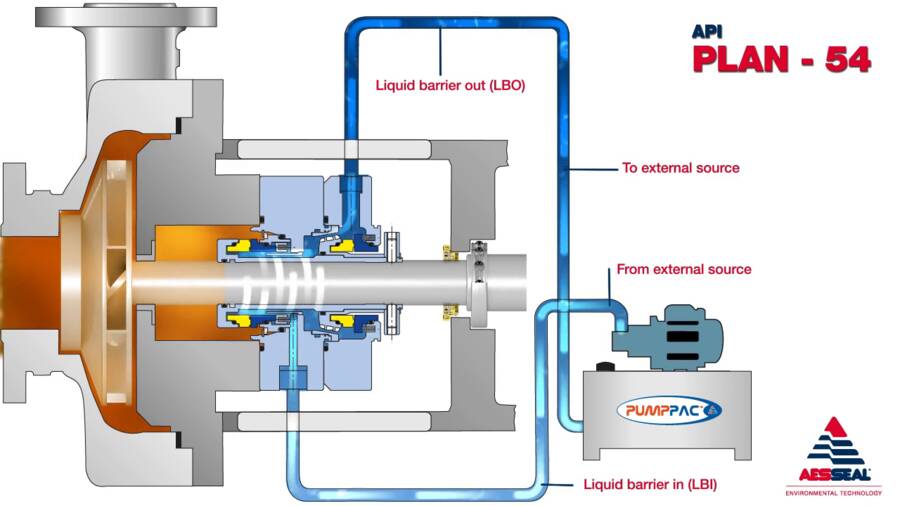

API Plan 54

Pressurised external barrier fluid circulation from a central pressure source or by a stand alone pumping unit (e.g. AESSEAL PUMPPAC™).

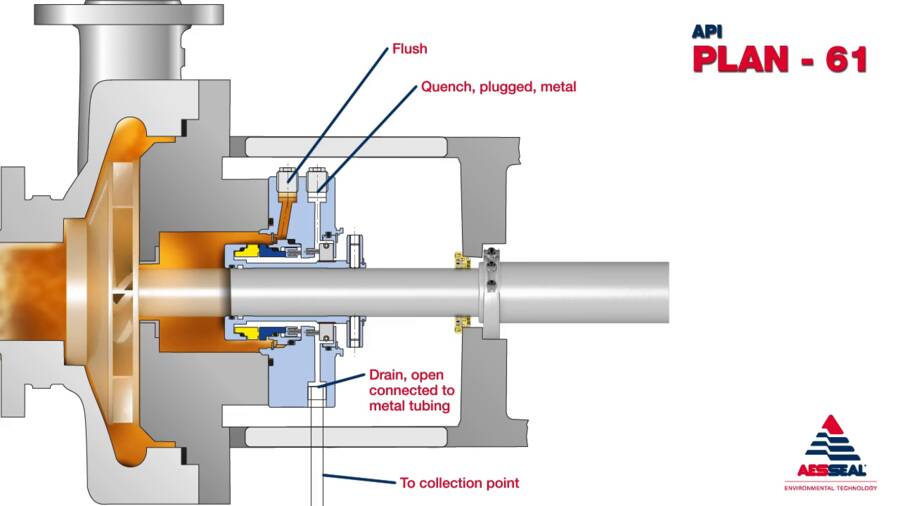

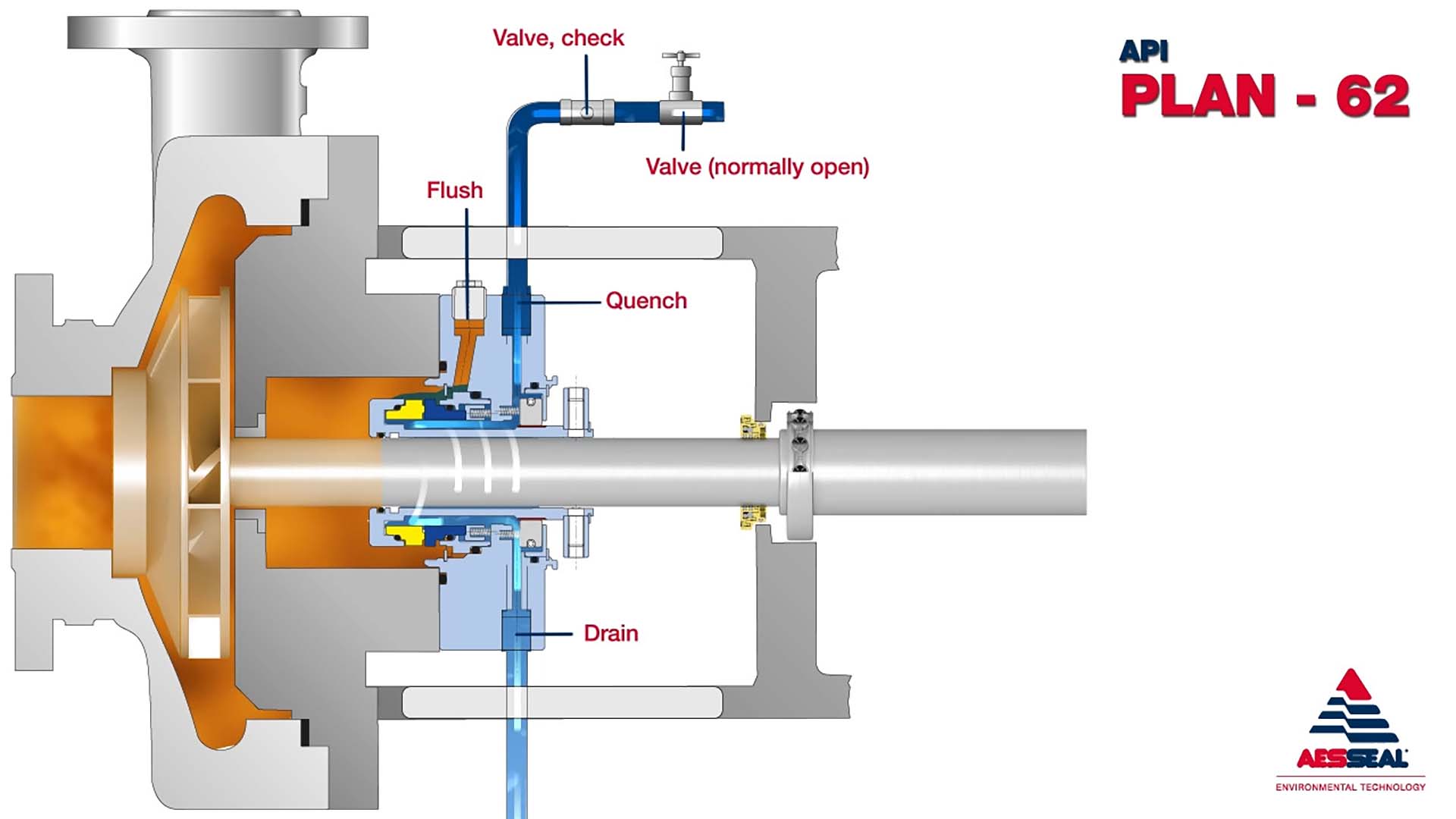

API Plan 62

An external fluid stream is brought to atmospheric side of the seal faces using quench and drain connections.

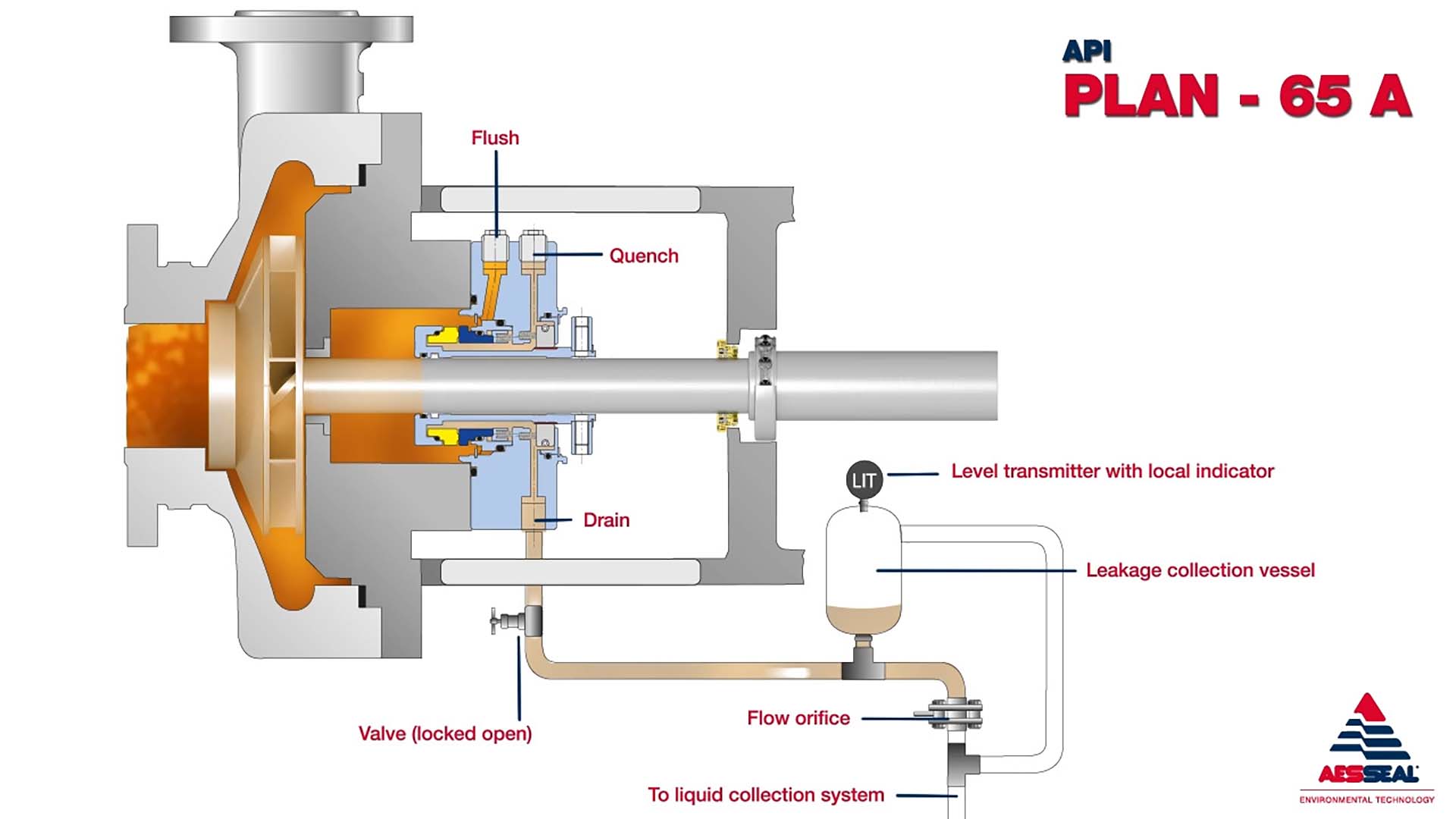

API Plan 65A

Leakage from seal faces is directed to a liquid collection system. A vessel with a high level alarm is provided for detection of excess leakage.

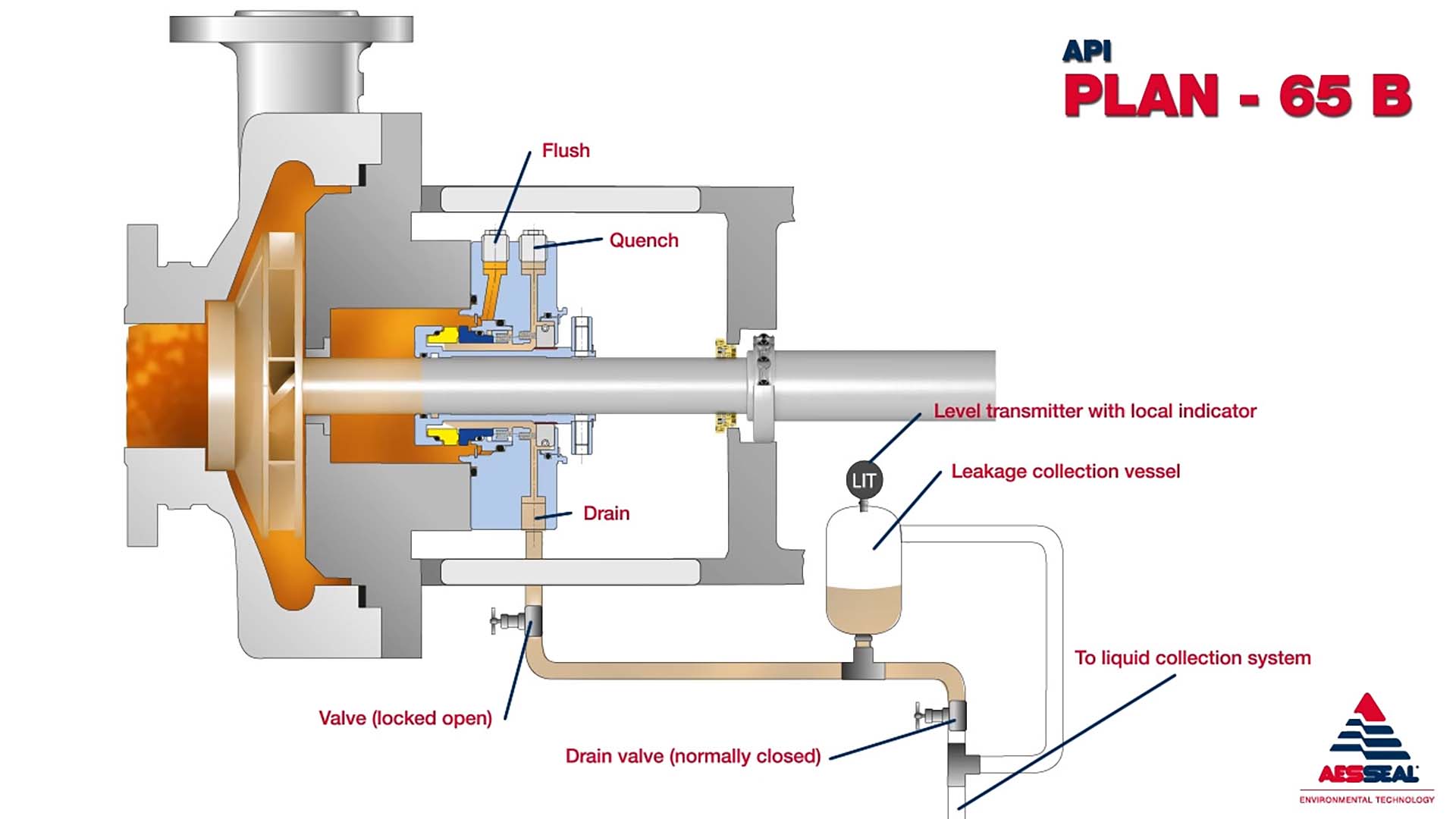

API Plan 65B

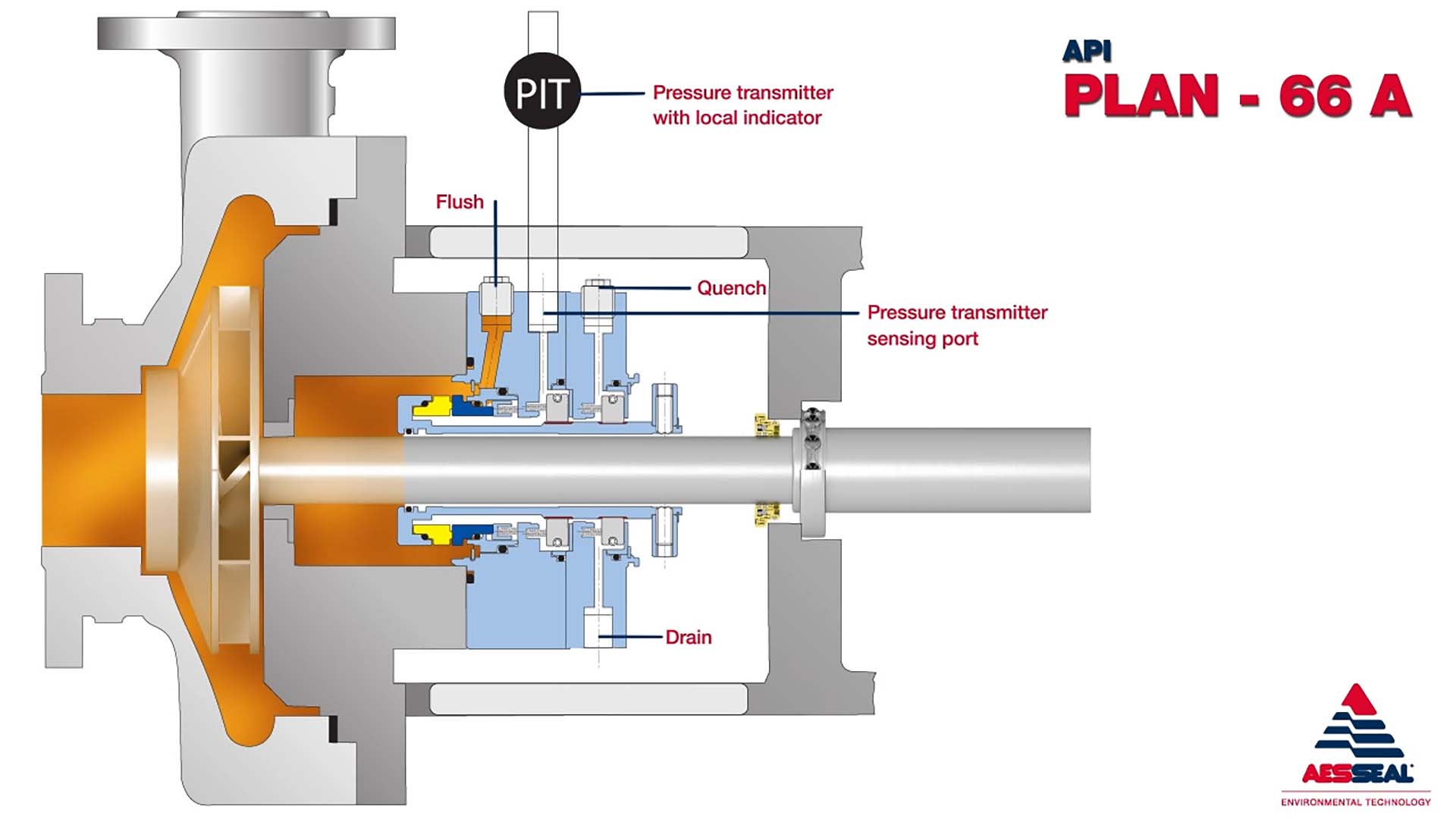

API Plan 66A

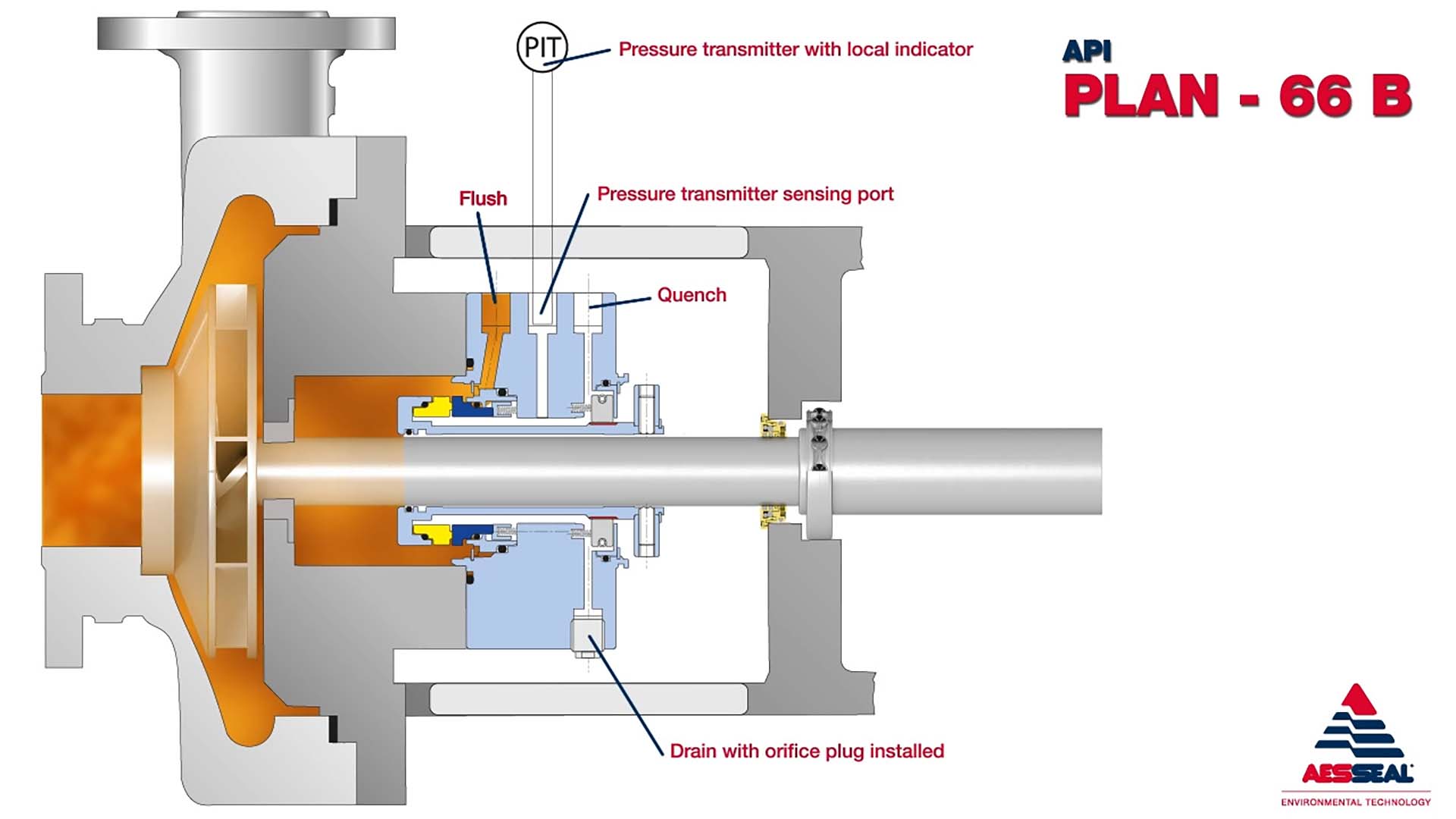

API Plan 66B

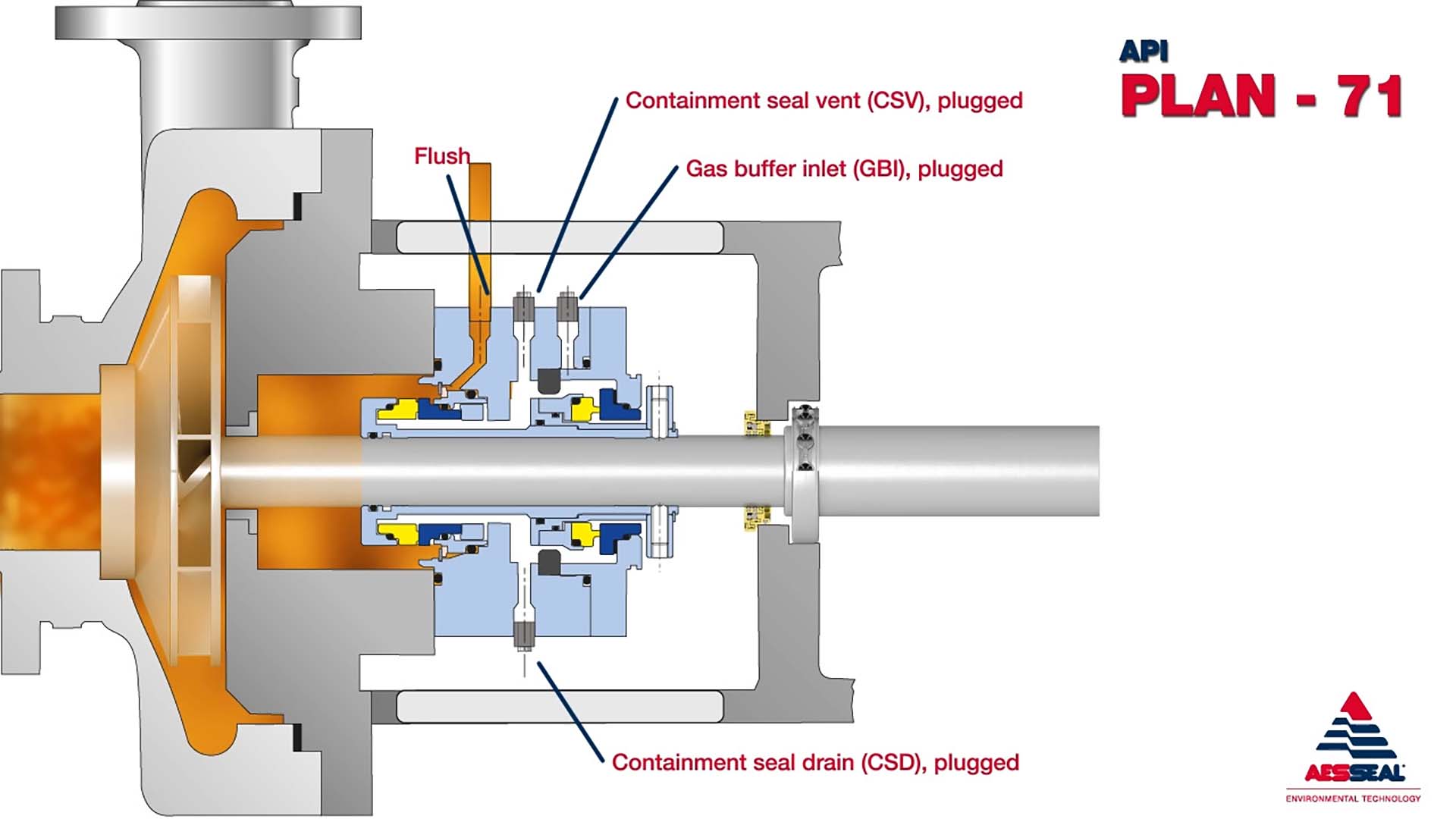

API Plan 71

Plugged connections for future provision to supply a buffer gas to a dual containment seal.

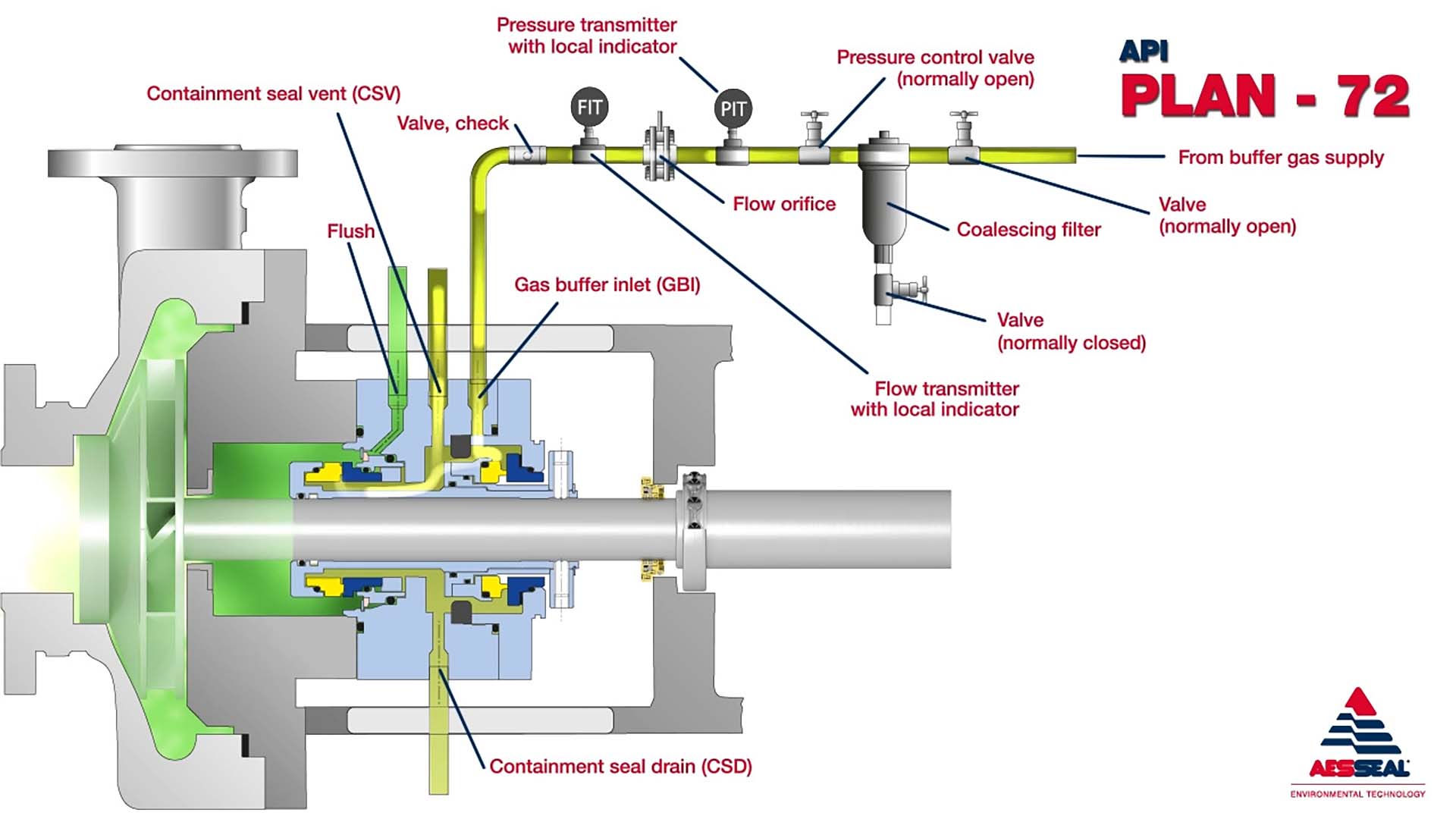

API Plan 72

Buffer gas is passed through the containment seal chamber to sweep inner seal leakage away from outer seal to a collection system and / or dilute the leakage.

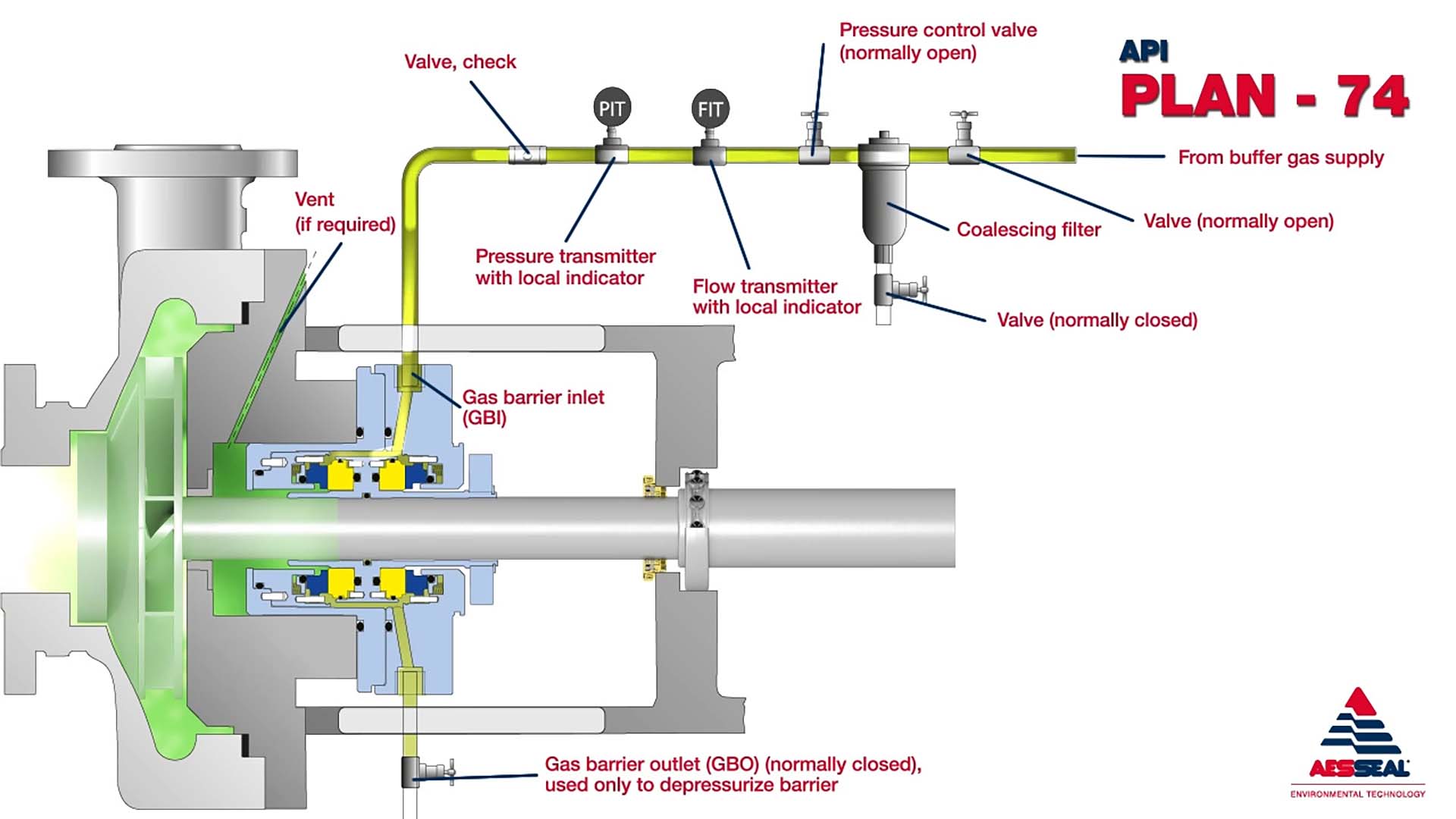

API Plan 74

Externally pressurised barrier gas supplied through a gas control system to a dual seal arrangement. An inert gas is used as a barrier gas.

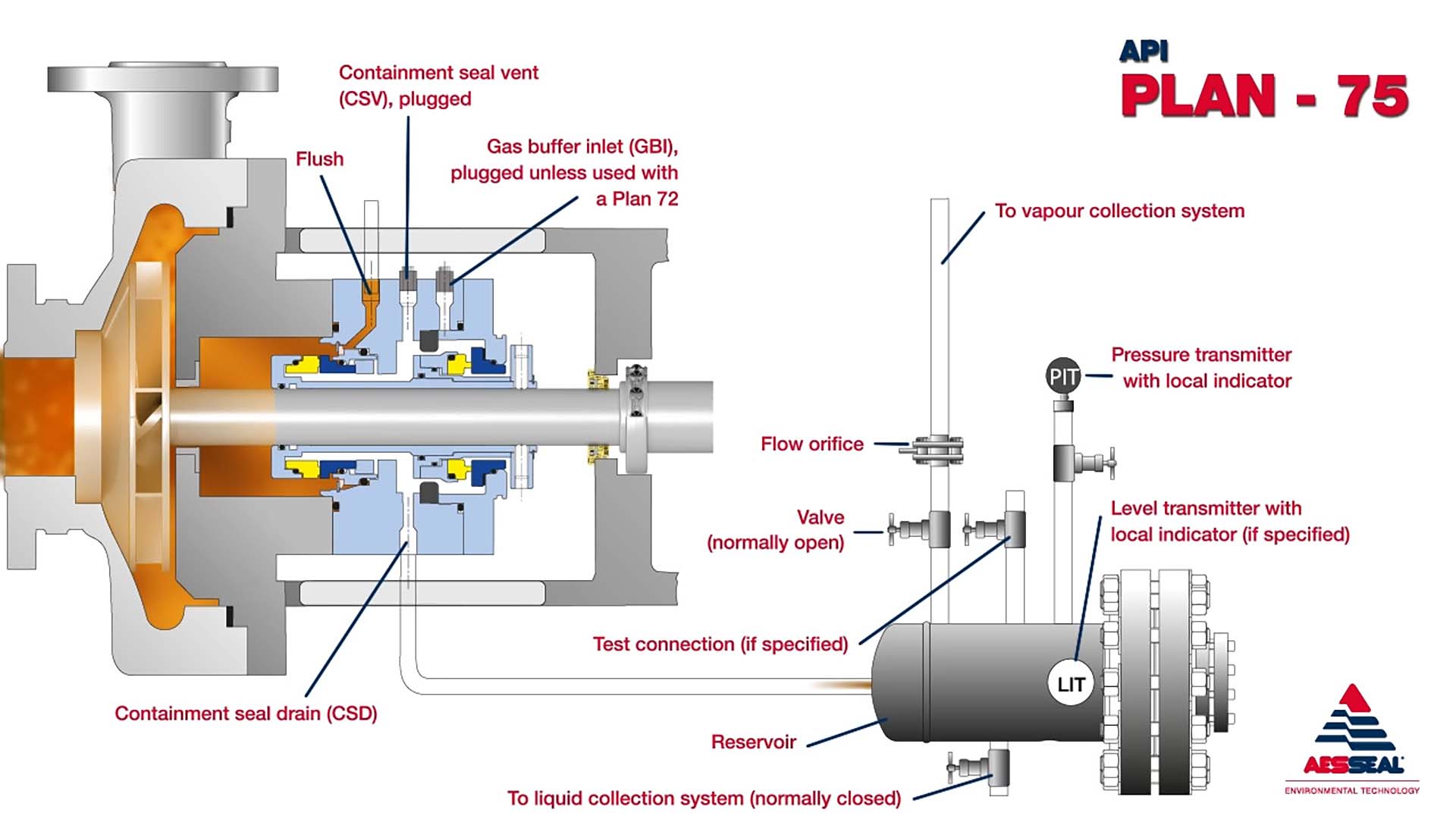

API Plan 75

Leakage of condensate from inboard seal of a dual containment seal is directed to a liquid collector.

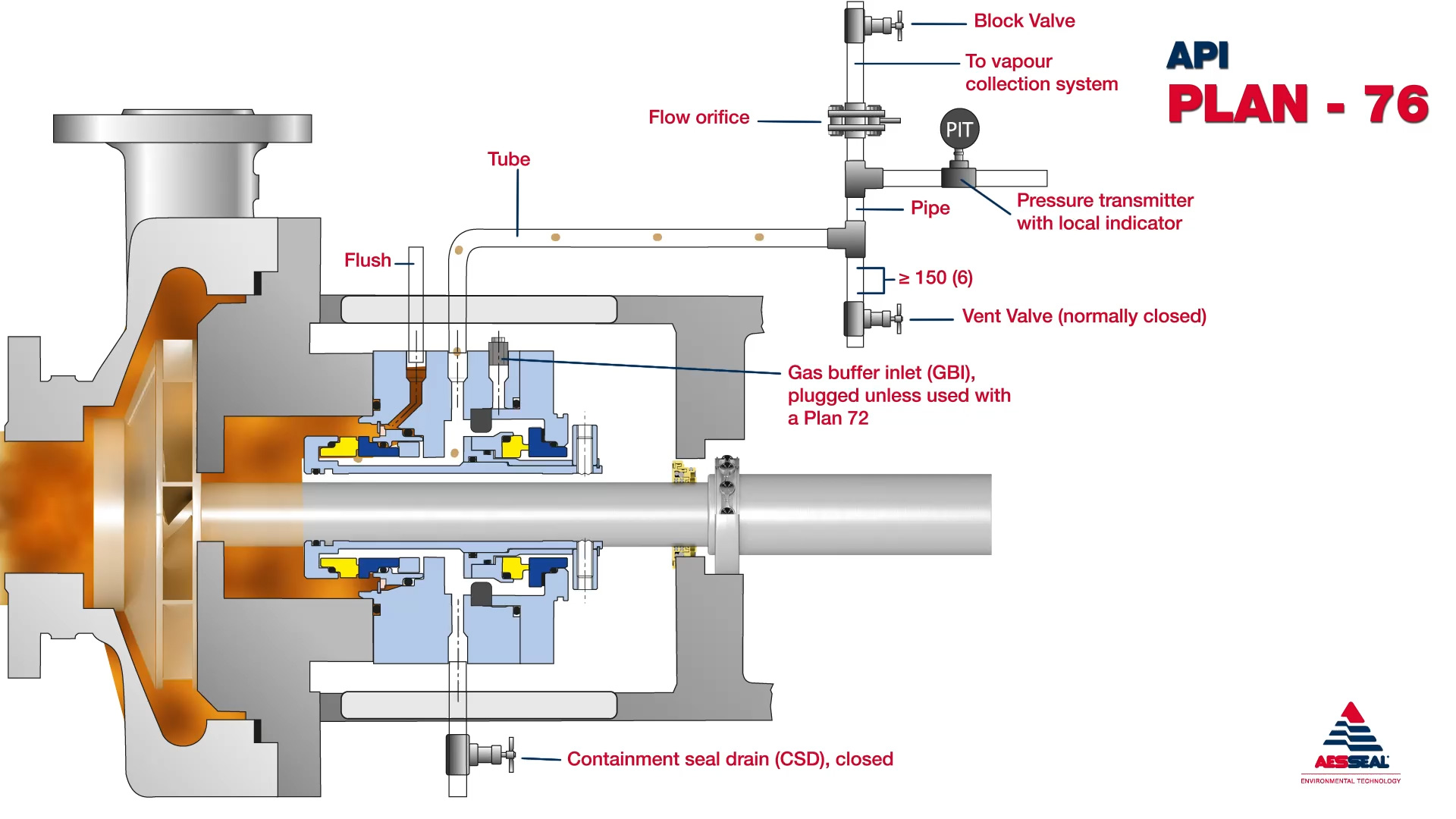

API Plan 76

Vapour leakages from inboard seal of dual containment seal are directed to a vapour recovery system via a vent connection.