Description

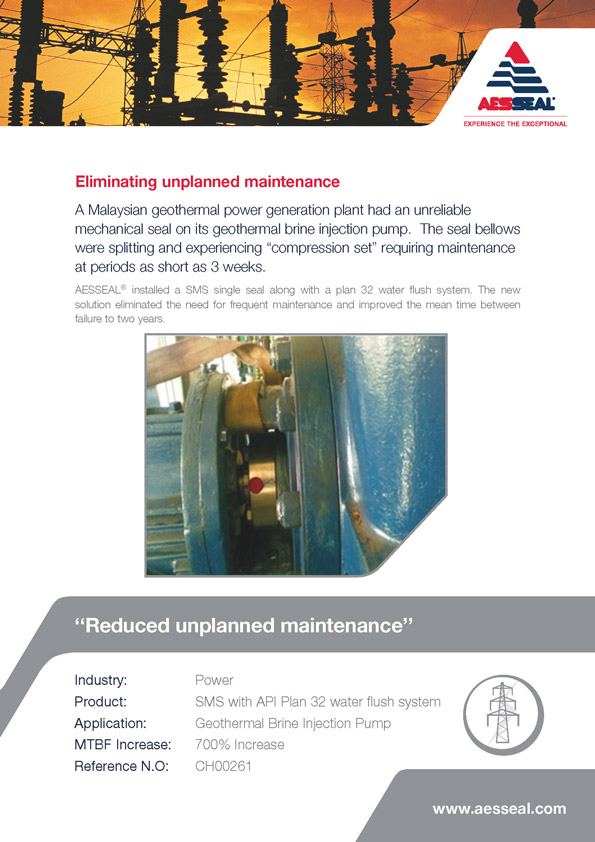

Injection of clean or cool liquid from external source into the seal chamber.

Features

- Reduces flashing or air intrusion across seal faces by providing a positive flush.

- Maintains vapour pressure margin.

- Always provided at a pressure greater than seal chamber pressure.

- If maintained properly the best of all single seal plans (subject to acceptance of contamination).

Use

- Dirty or contaminated fluids.

- High temperature applications.

- Polymerizing and oxidizing fluids.

- Media with poor lubrication properties.

Caution

- External source should be continuous and reliable at all times, even during start up and shut down.

- Flush fluid must be compatible with process fluid due to product contamination.

- Product degradation can occur.

- Ensure use with close clearance throat bushing to maintain pressure in stuffing box and control the rate of contamination of pumped media.

- Careful selection of flush fluid required to ensure that it does not vaporize on entering the seal chamber.

- Fluid expenditure of Plan 32 may be as expensive as one or more seals per year.