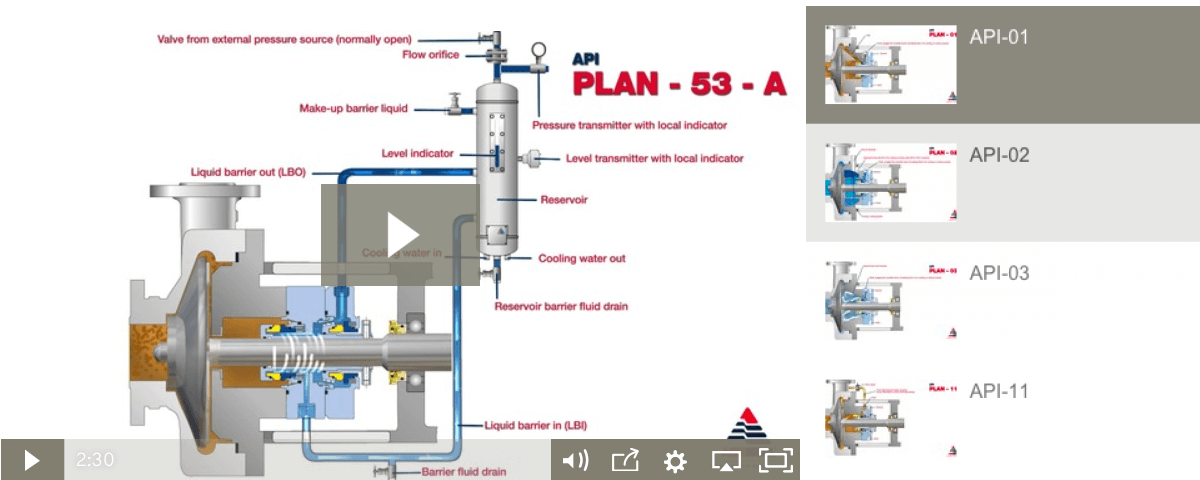

Description

Depressurised buffer fluid circulation in outboard seal of a dual seal configuration through a seal support system. Circulation is maintained by using pumping ring in running condition and by thermosyphon effect in stand still condition.

Features

- No process contamination.

- No direct process leakage to atmosphere.

- No need to maintain pressure system as in Plan 53A.

Use

- For media where product dilution is not allowed but leakage to atmosphere in diluted form may be allowed.

- Preferred for clean, non-polymerizing media with vapour pressure higher than buffer fluid pressure

(Is also used for lower vapour pressure media).

Caution

- Keep the sealant vessel vent continuously open, which is necessary to maintain buffer fluid pressure close to atmospheric pressure and vent the vapors to flare.

- Should not be used in dirty or polymerizing products.

- A restriction orifice is necessary in vent line to maintain back pressure in pot and facilitate quick release of vapors to flare.

- Pressure switch setting should be done above minimum flare back pressure in order to avoid false alarms.

- Never run the system with level in the sealant vessel being at low level as marked on the level gauge.

- Check for temperature difference in inlet and outlet lines to ensure that circulation is on.

- Vent the system properly before start up.