Description

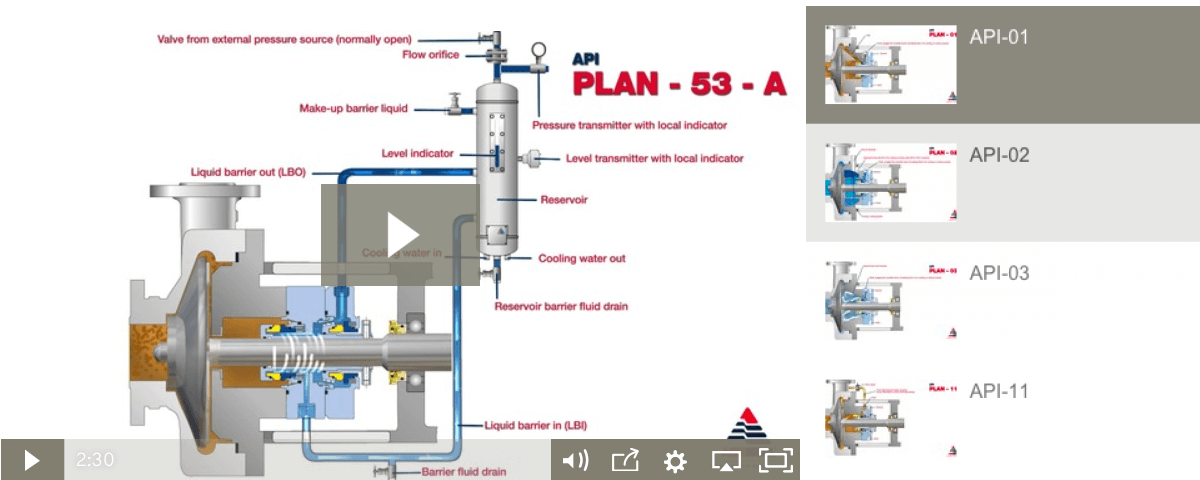

Pressurised barrier fluid circulation in outboard seal of dual seal configuration. Circulation is maintained by using pumping ring in running condition and with thermosyphon effect in stand still condition. The pressure is maintained and fluctuations are compensated in the seal circuit by a piston type accumulator.

Features

- Vent system properly before start up.

- Heat is removed from the circulation system by an air-cooled or water-cooled heat exchanger.

- In no case will the media leak to the atmosphere.

- Clean fluid film formation between the inboard seal faces gives better seal life.

- This allows successful operation of dual seals lacking reverse balance feature at inboard seal, when having highly variable seal chamber pressure.

Use

- Applications where no leakage to atmosphere can be tolerated e.g. hazardous, toxic, inflammable media.

- For dirty, abrasive or polymerizing products where media is unsuitable as a lubricant for inboard seal faces.

- Where pump pressure varies during operation needing an auto setting of barrier fluid pressure, thus maintaining the same differential throughout.

Caution

- Always connect reference pressure line from seal chamber to accumulator and keep it open.

- There will always be some leakage of barrier fluid into the product. Check compatibility of barrier fluid with product.

- Vent the system properly before start up.

- Product quality can deteriorate due to barrier fluid contamination.