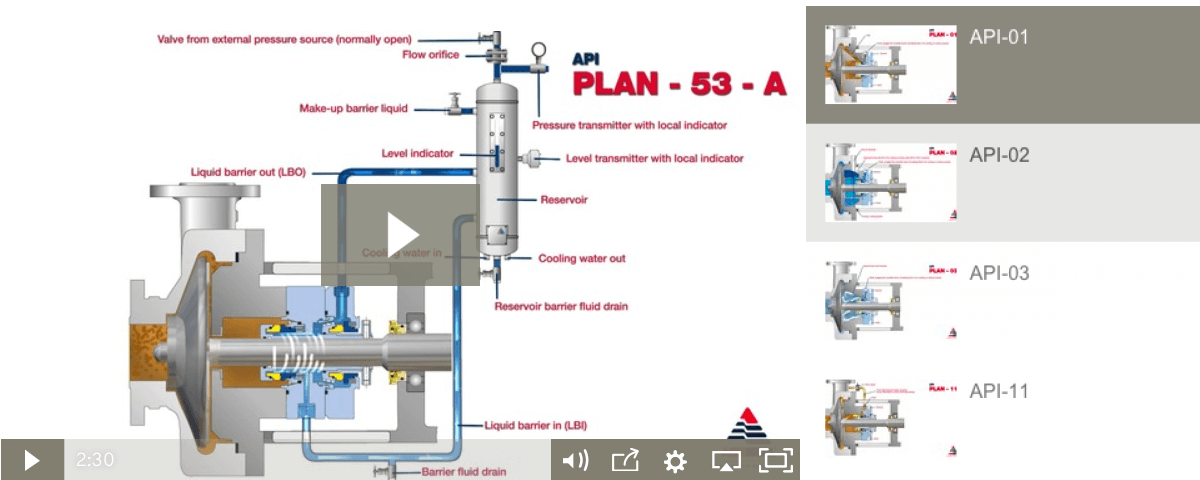

Description:

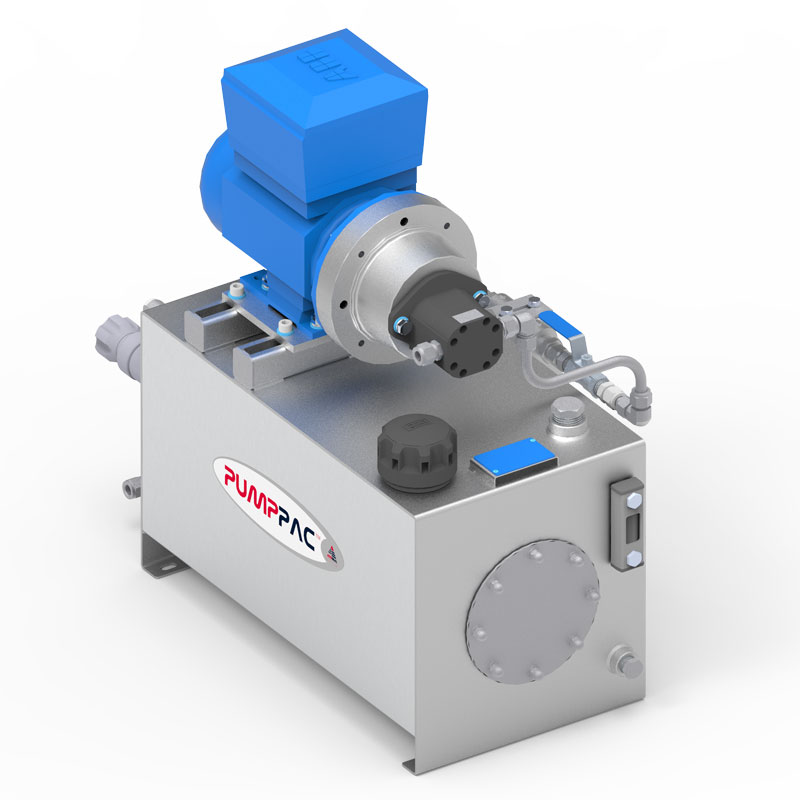

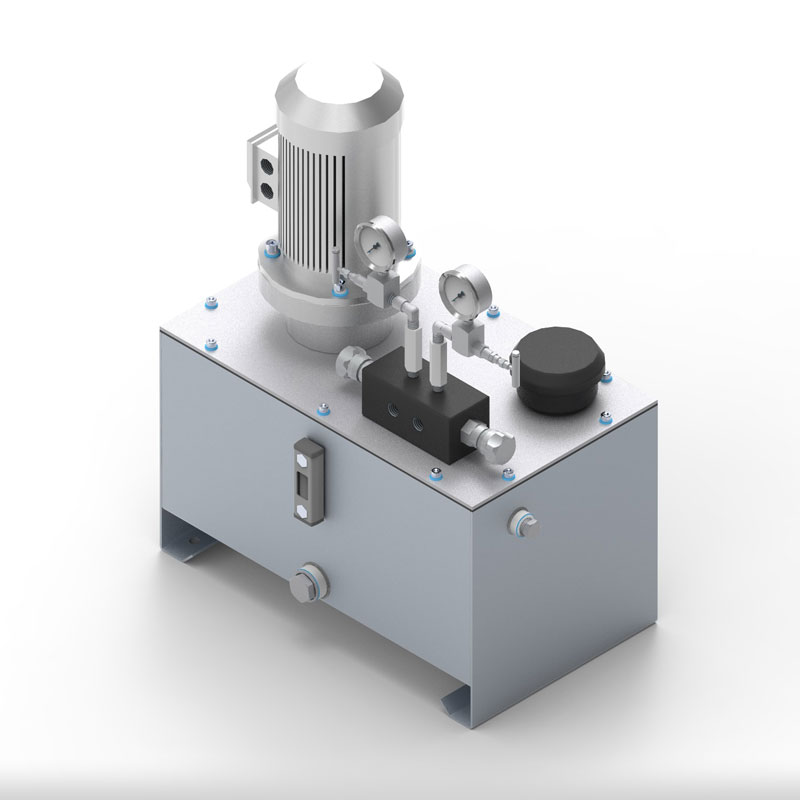

Pressurised external barrier fluid circulation from a central pressure source or by a stand alone pumping unit (e.g. AESSEAL® PUMPPAC™).

Features:

- Ensures higher flow rate, better heat dissipation and positive circulation of barrier fluid.

- If maintained properly, is the most reliable pressurised plan for dual seals as compared to Plan 53 A/B/C.

- Can also be given as a stand alone unit per pump.

- Increases cooler efficiency due to higher flow rate the heat exchanger.

Uses:

- Applications where no leakage to atmosphere can be tolerated e.g. hazardous, toxic, inflammable.

- For dirty, abrasives or polymerizing products where media is unsuitable as a lubricant for inboard seal faces.

- For media with high pressure and / or high temperature and / or high heat generation between faces.

- Wherever Plan 53 A/B/C circulation is insufficient to dissipate heat.

Caution:

- Carefully consider the reliability of barrier fluid source, if a central source is used.

- Expensive system, proper engineering required.

- Circulating system must be pressurised at least 1.5 bar greater that the pressure in the seal chamber.

- Product contamination does occur. Barrier fluid selected should be compatible with the process fluid.

- Always check filter / strainer in the system for any possible blockages.

- Loss of pressure in system can lead to entire barrier liquid contamination.

- Product quality can deteriorate due to barrier fluid contamination.