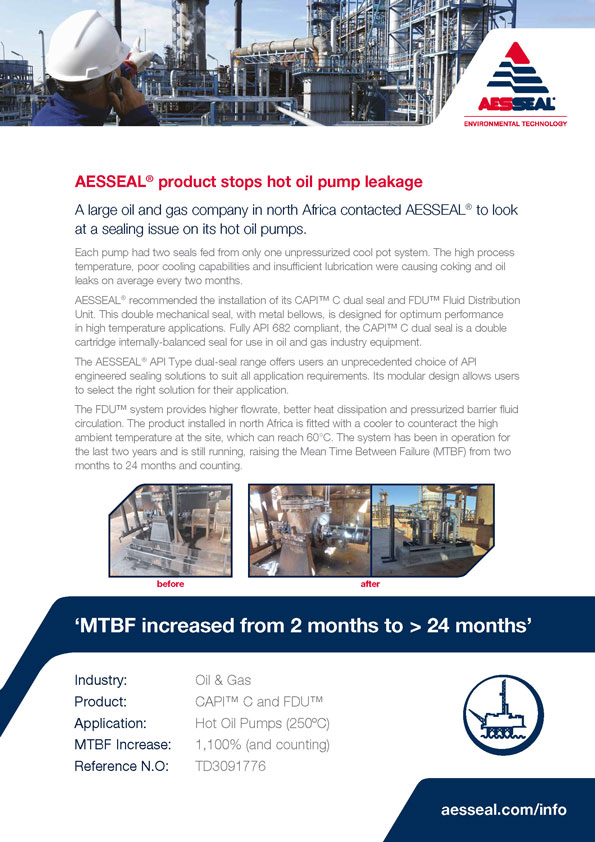

A large oil and gas company in north Africa contacted AESSEAL® to look at a sealing issue on its hot oil pumps.

More Industry Related Content

By Hocine Lazib

How did the contact with the customer originate? Were they existing customers?

No, they were not existing customers; it was a prospect that we met at an Oil & Gas fair. We had a short discussion with the maintenance manager, who was not very convinced. However, he invited us to visit the site for a Site Survey.

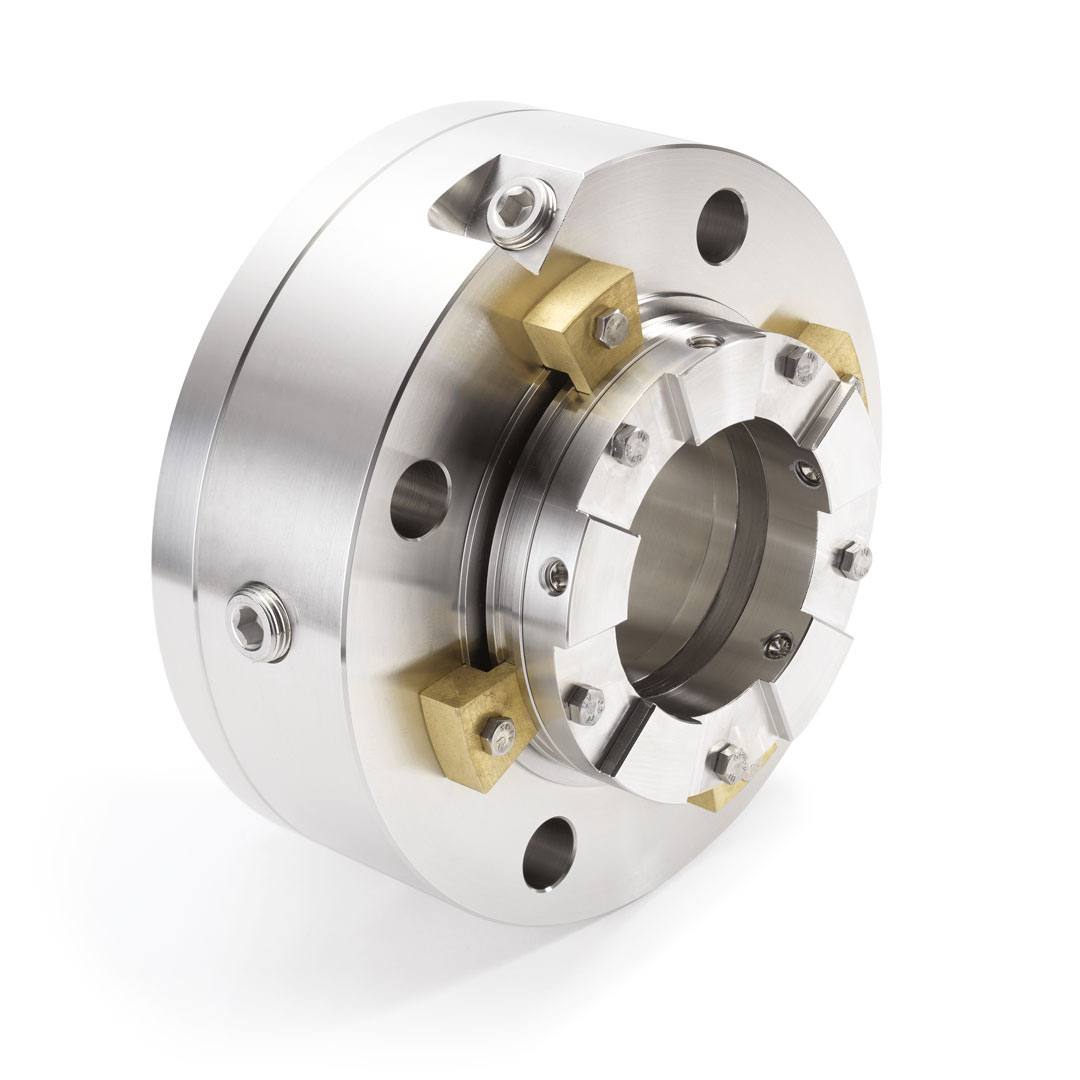

I remember this first visit well. We made a presentation of our products and services and the customer was eager to show us the problems they were having with the hot oil pumps. We understood from day one that these strategic pumps presented a major reliability problem. This presented us with an opportunity, and a challenge.

We asked the customer to tell us if other seal manufacturers, and particularly the OEM, had been asked to provide a solution. They said that that they had consulted several but that most of them were not interested in a dealing with such a problematic application.

On our first visit to the site, an operator explained the problems they were having with the pump, and it was immediately clear from what he told us that it was a nightmare. That was the moment I told myself that we had to meet the challenge of satisfying this customer.

Were there any problems installing the new system? If so, how did AESSEAL overcome these issues?

The installation of the new system was done at the start of COVID 19, so the most difficult thing was to cope with all the restrictions and maintain the continuity of operations with our subcontractors, while at the same time making sure that our factory was able to adapt to the new conditions.

For the site installation itself, we encountered a few small problems, but they were quickly resolved. The customer was very attentive and was just as keen as we were that we should succeed.

The success of the project was a great team effort, and was due to the professionalism of the AESSEAL team on site, in the back office and at the head office in Rotherham. Without such a high level of cooperation and teamwork, it would have been much more difficult to overcome the challenges. It gave us the chance to demonstrate both the quality of our products and the passion throughout the company to provide an exceptional standard of customer service.

The installation was done in several stages so as not to disturb our client's production. As part of our AVT Reliability service we also carried out preventive maintenance actions and a vibration survey. This involved taking dozens of vibration measurements for each pump, and making some recommendations where necessary.

Is the customer satisfied with the way the product is performing since installation and has it led to any new contracts with this company or other companies who may have heard of AESSEAL?

The client is very satisfied with the result. The MTBF went from two months to more than two years, and to date no mechanical seal has leaked on the total 12 CAPI C installed on this site.

In fact, since carrying out this installation, the customer has asked us to carry out further repair work on dry mechanical seals and wet seals. We are convinced that this project will serve as a reference for AESSEAL and will open many doors for us in the future.

While Oil & Gas is the largest industrial sector in Algeria, we do not base our development strategy on this sector alone. We have a policy of diversification, and we also have customers and further opportunities in F&B, seawater desalination, and in the pharmaceutical business.