The seal on a pump at a chemical plant in the east of England was burning out on average every two weeks due to dry running, resulting in some four hours of downtime each time it failed. Leakage of product was also causing a slip hazard in the work area.

More Industry Related Content

More API Related Content

By Oliver Crank

How did AESSEAL® get involved? Was this an existing customer?

They were already customers of ours. We had recently solved a big problem for them by sourcing parts at short notice for the mechanical seal on one of their reactors. That involved a team of our engineers building a highly engineered reactor seal over the course of a weekend. Installing this 45mm DMSF was to solve a problem the customer asked us to look at after we had helped them get their reactor up and running.

What was the existing competitor’s seal? Was the leakage a serious problem?

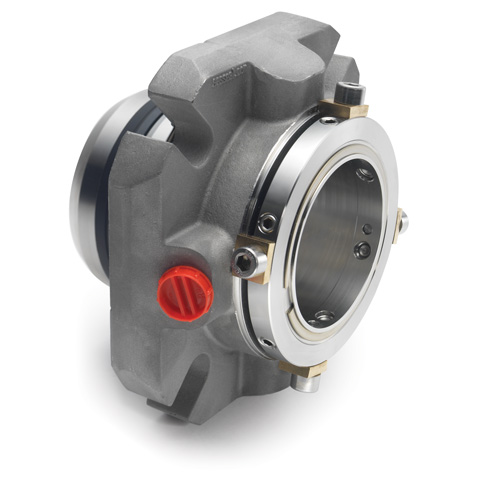

The competitor’s seal was a single mechanical seal which was not suitable for the hot and arduous duty it was being asked to perform. The leakage of product was potentially very serious because it’s oil-based and therefore very slippery and hazardous to employees. The advantage of the AESSEAL® DMSF is that it’s a double seal with an integral pumping scroll which helps circulate the barrier fluid. Better barrier fluid flow results in lower temperatures at the seal faces. When operated as an API plan 53a the double seal keeps the seal faces lubricated and stops the product within the pump contaminating the seal faces and barrier system.

Were there any particular challenges with this installation?

I helped with the installation process from start to finish to ensure the seal would have a happy life. The process lines along with pump are regularly cleared by blowing them with steam to soften any product before start-up. Otherwise there is a risk that the pump will spin and the seal will run without lubrication. This generates excess heat and burns out the faces along with O-rings. A double seal offers better protection against this.

Do you still monitor the performance of the seal?

I visit regularly and work with various people onsite including the reliability manager. I still monitor the performance and we have a packet of biscuits on the annual anniversary as a small celebration. Everybody on site is aware of this successful upgrade. After they realised this improvement could be so beneficial they have been keen to roll it out on other problematic applications that also have the potential to leak and present a slip hazard.

Do you have any updates about the performance of the seal? Is it still going?

The seal is still happily running and as long as the pressure and fluid in the P2 pressurised support system is maintained (API plan 53a) and the customer looks after the bearings/lubrication in the bearing housing on their pump then the seal should continue to run.

Finally, is AESSEAL still the company’s preferred supplier?

Yes. AESSEAL® is the preferred supplier and we are currently working on some large contracts/upgrades to continue to make similar improvements across the site.