We offer mechanical seals, seal support systems, bearing protectors and packing to suit all industries and our modular design means that we provide the best on-time delivery performance in the industry. Our business is built around giving our customers such exceptional service that they need never consider alternative sources of supply.

Content Library

UKCSI Results Confirm AESSEAL’s Leadership in Customer Service

Rapid response impresses Saudi customer

Sourced and supplied a replacement seal in just two weeks for customer’s Oil and Gas operation in Saudi Arabi

AESSEAL is always available to help when needed

A South African mining company was continually being forced to halt operations at one of its plants when a competitor’s seal persistently failed at start-up.

Style 343 a lasting solution for Gulf power company

Problems with gland packing prompted a power and desalination plant in the Middle East to turn to AESSEAL® in search of a solution.

Autoclave specialist chooses AESSEAL for reliability and customer service

A Turkish phosphate fertiliser was established following a requirement for Turkey to produce most its own phosphate fertiliser.

Standard of service makes AESSEAL a clear winner

The seal on a pump at a chemical plant in the east of England was burning out on average every two weeks due to dry running, resulting in some four hours of downtime each time it failed.

Exceptional service saves thousands in lost revenue

AESSEAL were contacted by a power plant in the UK who were experiencing a major issue with their supply of mechanical seals.

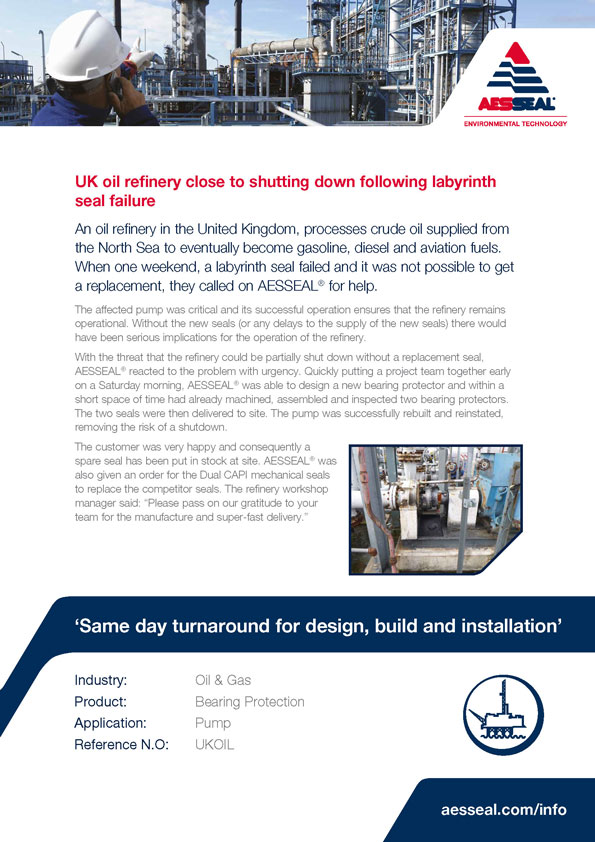

UK oil refinery close to shutting down following labyrinth seal failure

AESSEAL maintains Authorised Economic Operator (AEOC) status, reducing delivery times for Global Customers

AESSEAL voted UK leader in customer satisfaction

AES Engineering global expansion continues with acquisition of Vibtech Analysis in Canada

AESSEAL NSW Pty Ltd launched in key Australian investment

AES Engineering strengthens the Canadian market with acquisition of PCS Sealing, Edmonton, Canada

Quality of service key to AESSEAL contract

Reliability Improved For Waste Energy Company

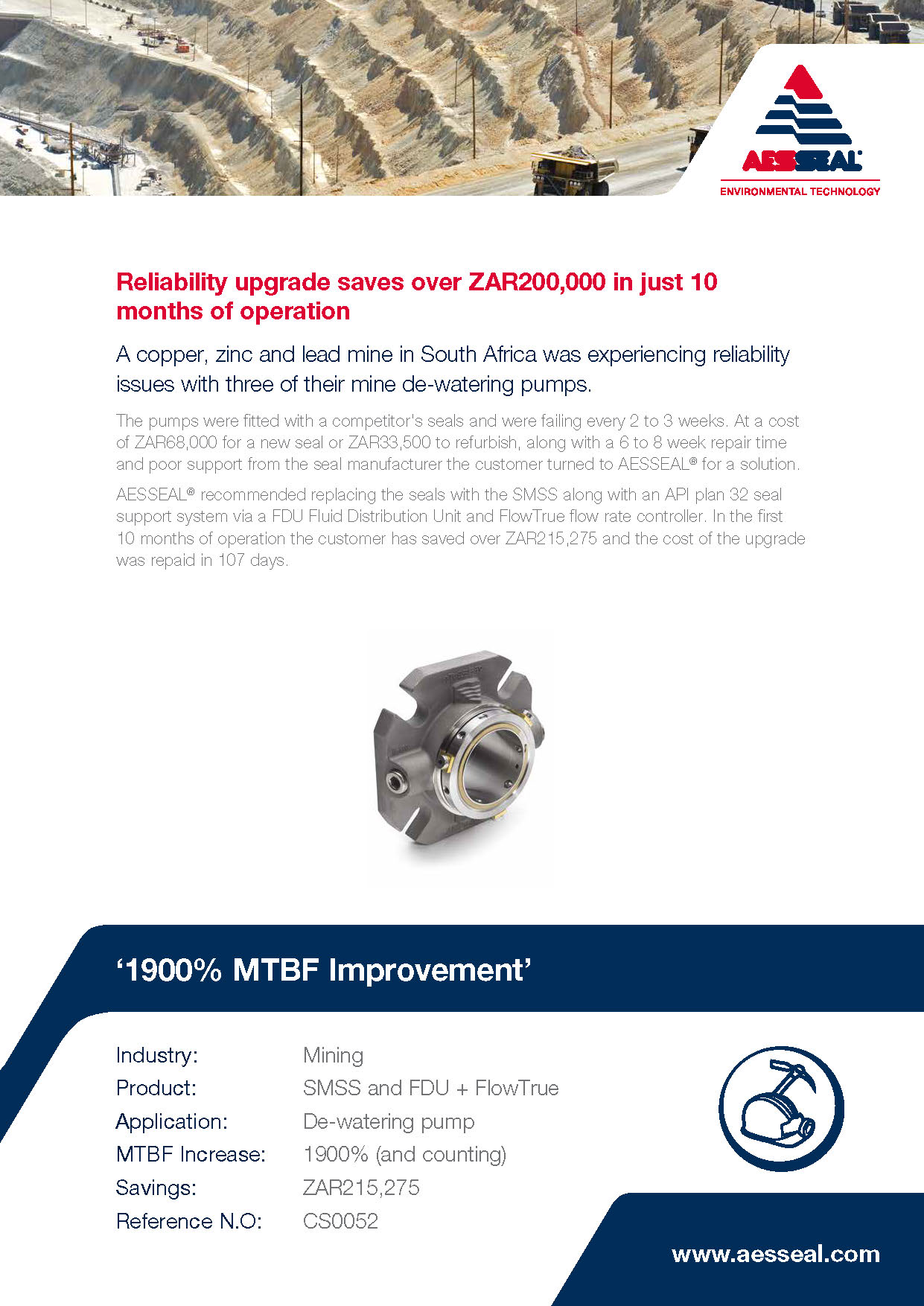

Reliability upgrade saves over ZAR200,000 in just 10 months of operation

Reliable solution for high pressure, high temperature agitator application

Tailored seal solution cuts costs and operational downtime

Seal upgrade saves cornmill $280,000 in repairs and downtime

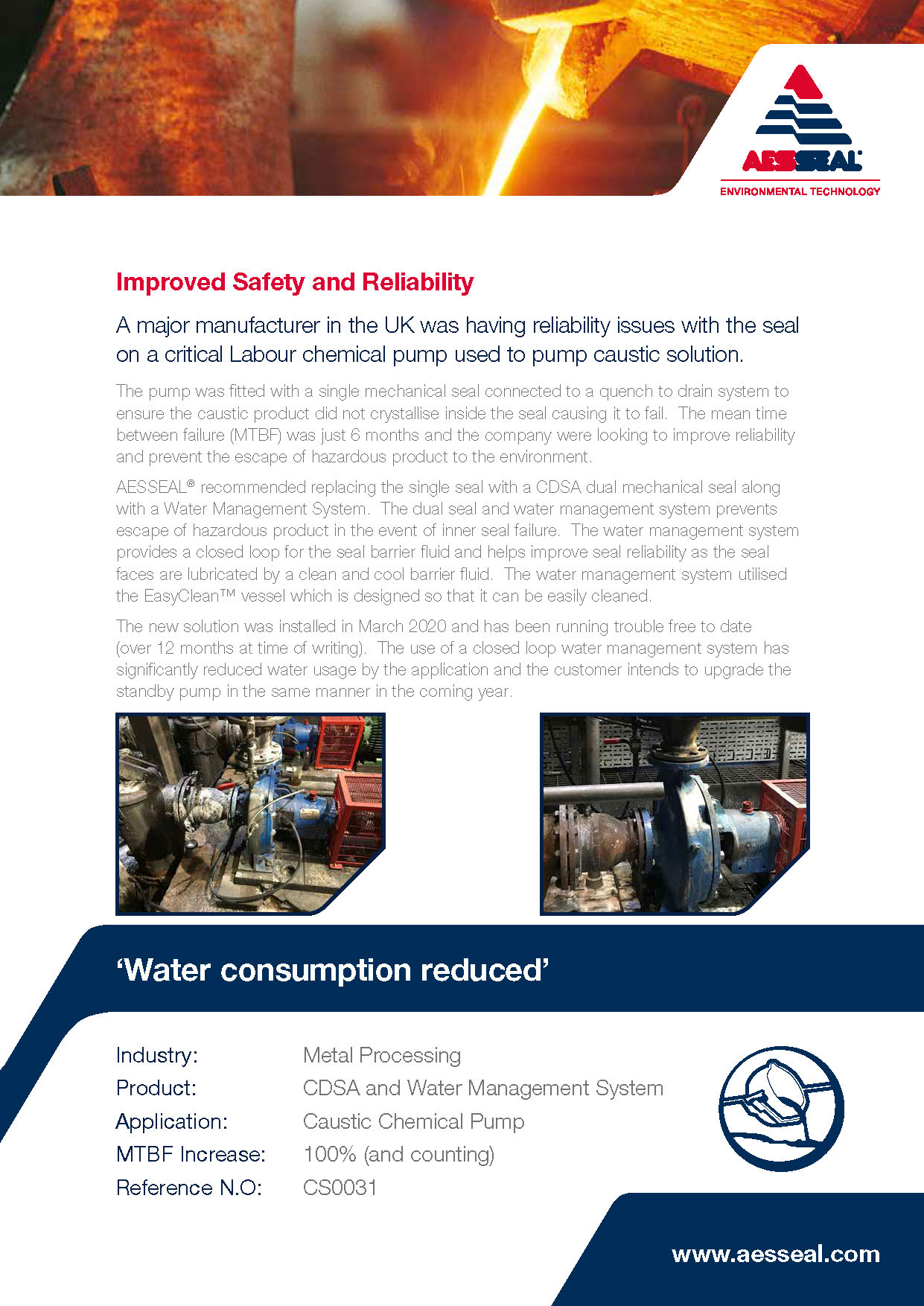

Improved Safety and Reliability

Chemical company saves over $225,000 in first year

Unique solution saves $287,000 a year and improves safety

Chemical Producer Saves Over £1.7 Million in Plant Downtime

Catalogue of issues lead to failures on power station valves

Service Level Update, In Light of the COVID-19 Outbreak

Major investment in US manufacturing division

AEO status to cut waiting times for global customers

AESSEAL named Business of Trust Champion in national awards

A leader in customer satisfaction, says independent survey

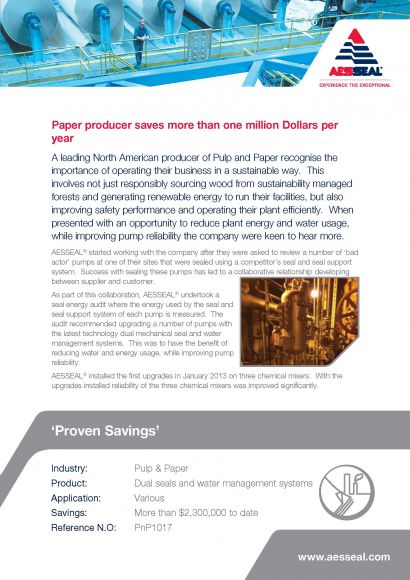

Paper producer saves more than one million Dollars per year

Huge cost savings and improved reliability with gland packing upgrade

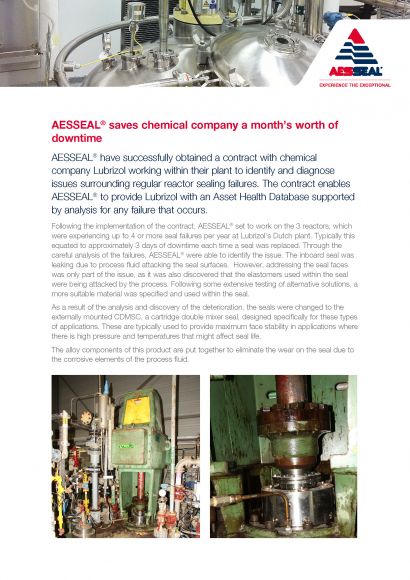

Chemical company saves a months worth of downtime

Queen's Award for AESSEAL

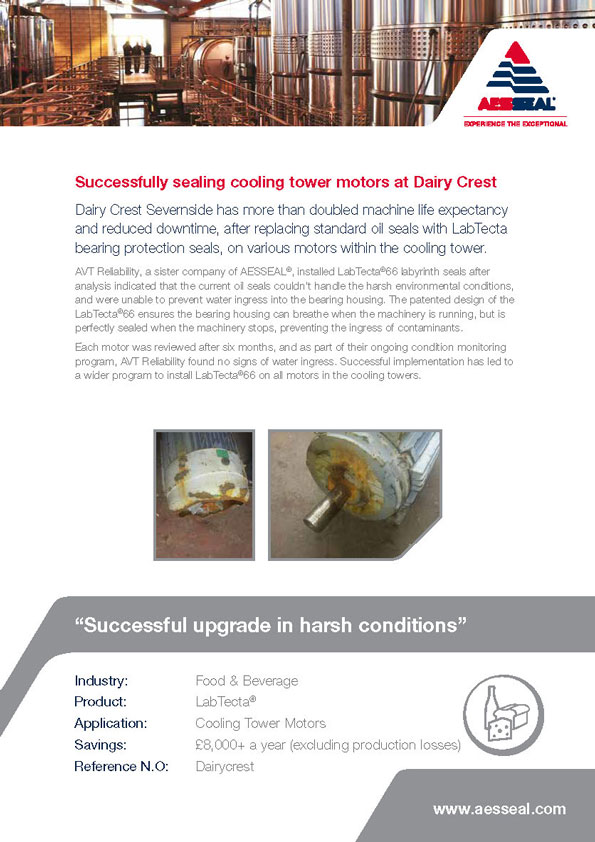

Successfully sealing cooling tower motors at Dairy Crest

DMSF upgrade saves over £460,000 a year

Eliminating a $225,000 maintenance bill

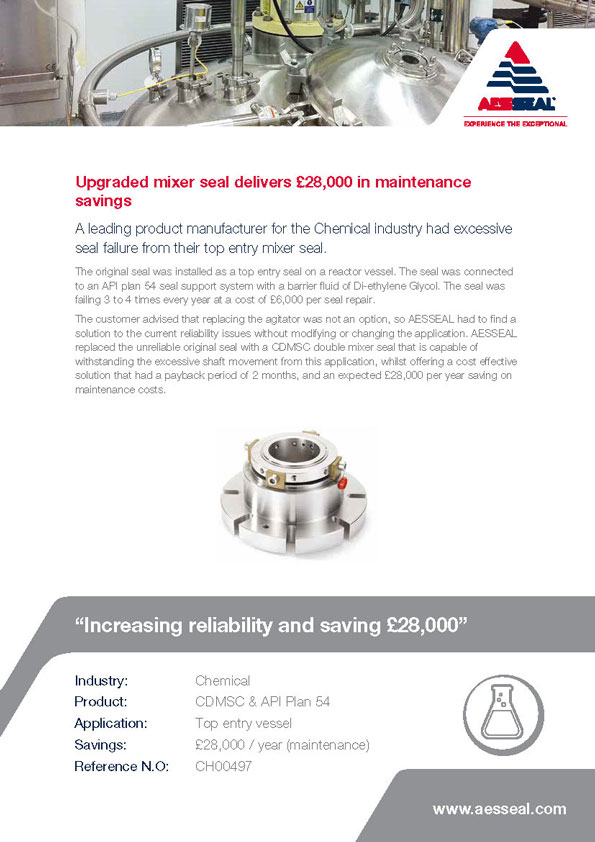

Upgraded mixer seal delivers £28,000 in maintenance savings

Helping to keep the water flowing for South Australia