MINExpo 2012 Water Session

Extending Pump Life by Changing the Environment of Mechanical Seal Operation

Extending Seal Life

Plan 23 offers improved vapor pressure margin in the seal chamber to extend seal reliability. The reduced working temperature of the seal from Plan 23 operation prevents coking on the atmospheric side of many mechanical seals

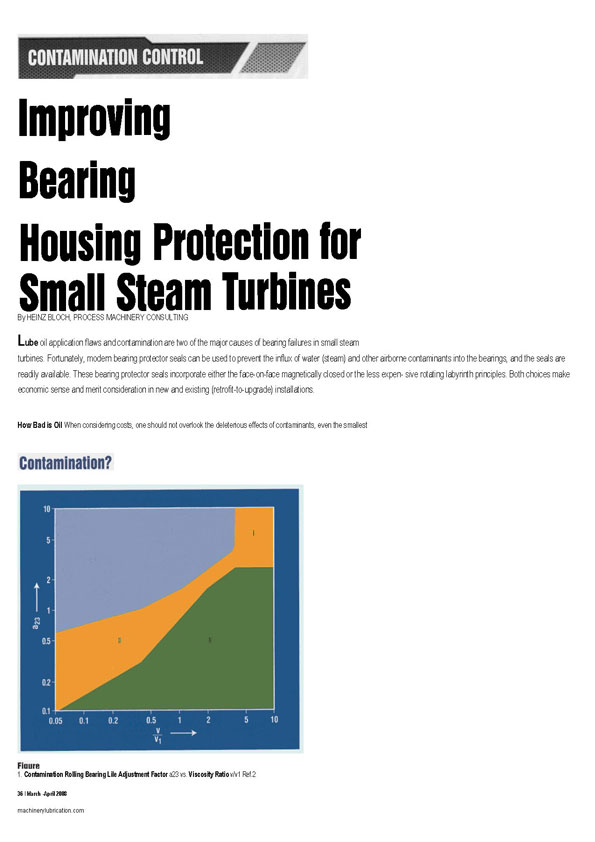

Improving Bearing Housing Protection for Small Steam Turbines

Lube oil application flaws and contamination are two of the major causes of bearing failures in small steam turbines.

Contribution to Energy Efficiency

Sealing devices account for only a small fraction of the energy consumed by pumps; the scope for energy conservation at first appears limited. However, the paper details areas where significant energy conservation has been achieved by elegant sealing practices.

LabTecta Life Expectancy

This article examines the statistical life expectancy of the LabTecta bearing protector, supplied by AESSEAL over a seven year period.

Applying low emission API compliant sealing technology to mature pump machinery

Contradicting requirements in API 682 dual seal design configurations

API Air Test Analysis: Further Information

Contain 'Normal' leakage from primary seals

Advances in dry gas seal technology for compressors

Centrifugal process gas compressors, and also certain rotary compressors, require sealing elements between the pressurized gas-containing volume and the bearing assemblies that support the compressor rotor.

The API 682 Standard 4th Edition

Our guide to the 4th Edition of the API 682 Standard, What's changed and how it relates to shaft sealing systems

Secondary Dry Containment Seals

Containment Seal Test Procedure

To test the integrity of mechanical seals fitted with a secondary containment seal.