Centrifugal process gas compressors, and also certain rotary compressors, require sealing elements between the pressurized gas-containing volume and the bearing assemblies that support the compressor rotor. A variety of different seal types and styles have been available for decades.

In the majority of these seals, lubricating oil serves as the fluid that separates rotating from stationary sealing elements. The barrier oil for these “wet” compressorseals is typically introduced at pressures of approximately 30 psi (2 atm) higher than the opposing compressed process gas. Wet seals require a seal oil supply system that generally includes an oil reservoir, two or more oil pumps, filters, coolers, valves and control instrumentation.

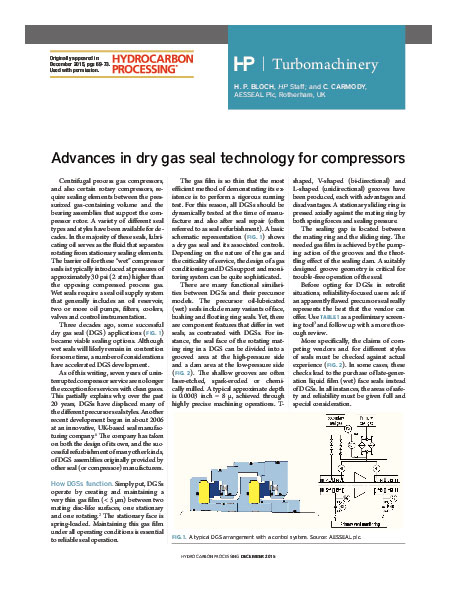

Three decades ago, some successful dry gas seal (DGS) applications (FIG. 1) became viable sealing options. Although wet seals will likely remain in contention for some time, a number of considerations have accelerated DGS development. As of this writing, seven years of uninterrupted compressor service are no longer the exception for services with clean gases.

This partially explains why, over the past 20 years, DGSs have displaced many of the different precursor seal styles. Another recent development began in about 2006 at an innovative, UK-based seal manufacturing company. The company has taken on both the design of its own, and the successful refurbishment of many other kinds, of DGS assemblies originally provided by other seal (or compressor) manufacturers