Recommended Products in this Industry

AESSEAL® have a wide range of sealing solutions suitable for use in the power generation industry.

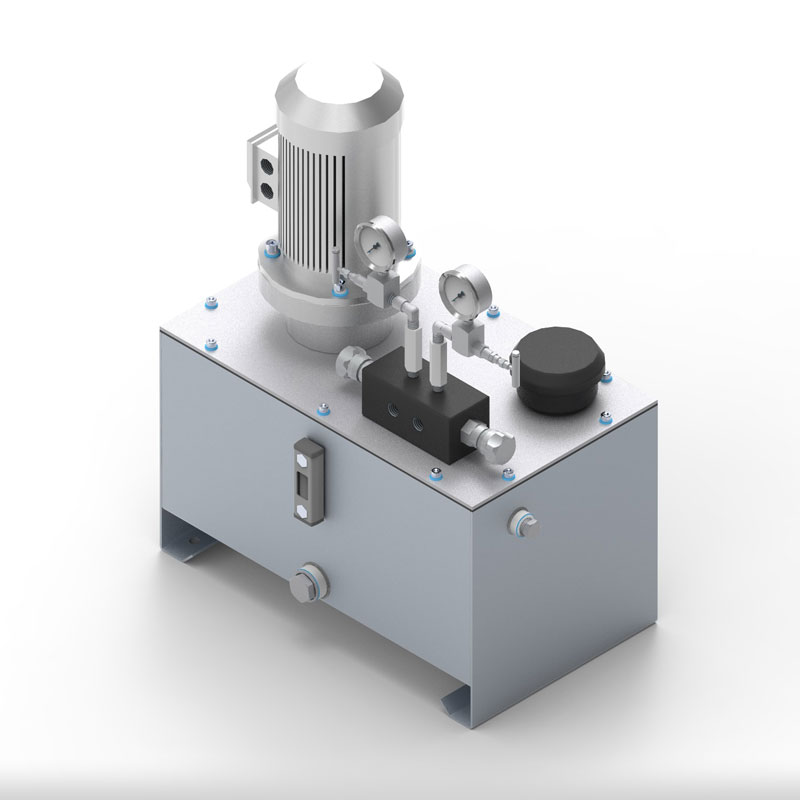

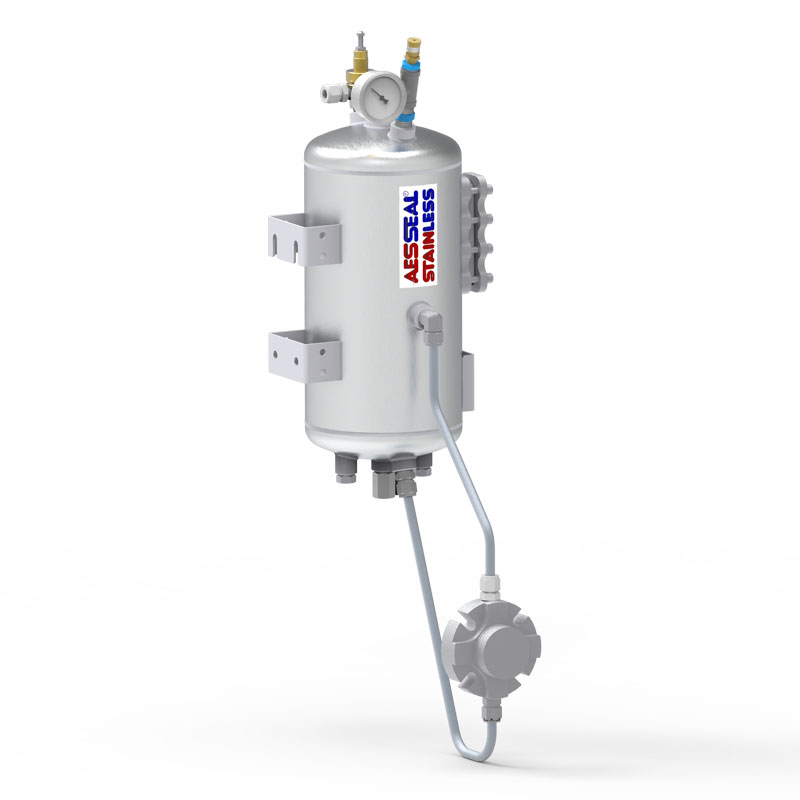

From bearing protectors that prevent the ingress of coal dust into bearing housing to seals for gas compressors. The solution are proven to improve reliability and backed up by some of the industries best customer service levels.

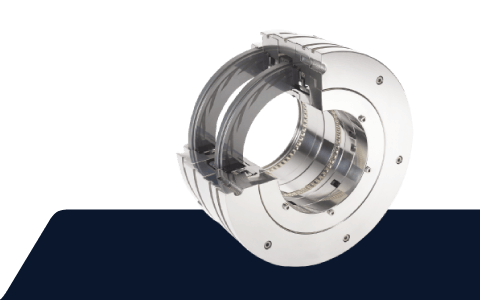

The FGDSS-N seal has been specifically designed for use with coal slurry and on the Flue Gas Desulphurisation / scrubber plant. The FGDSS-N can deliver improved reliability. The RDSX™ split seal is ideal for large service water pumps as the seal can be installed without having to remove the pump shaft.

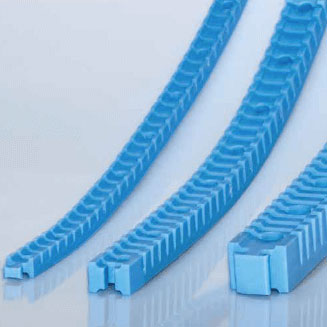

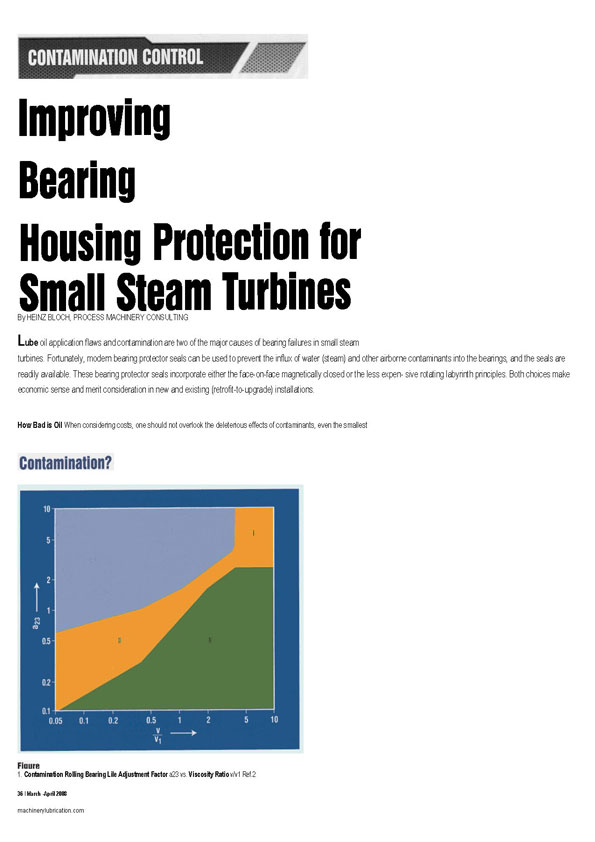

With more than 50% of the operational sealing issues in a coal-fired power station are due to bearing failures as a result of the ingress of coal dust to the bearing chamber inadequately protected by lip seals. AESSEAL® bearing protection products offer superior protection ensuring coal dust stays out and bearing lubrication stays in thereby improving the reliability.

Industry Solutions

Coal

AESSEAL® has product solutions to cover all applications in a coal-fired power station. From installing split mechanical seals on large service water pumps to engineered seals and systems for high pressure boiler feedwater pumps, AESSEAL® has one of the broadest range of products in the industry.

Special solutions address causes of premature failure: such as bearing protection seals with an IP-66 rating to exclude water and coal dust or mechanical sealing solutions that work even when the FGD absorber injects air creating unstable fluid film conditions.

Oil

Oil-fired power stations contain many arduous applications that present specific sealing challenges. AESSEAL® has developed technologies that provide reliability increasing solutions for such applications. Please contact your local AESSEAL® representative to discover more about our expertise in your industry.