- Home

- Product Index

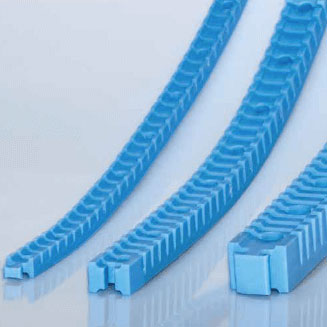

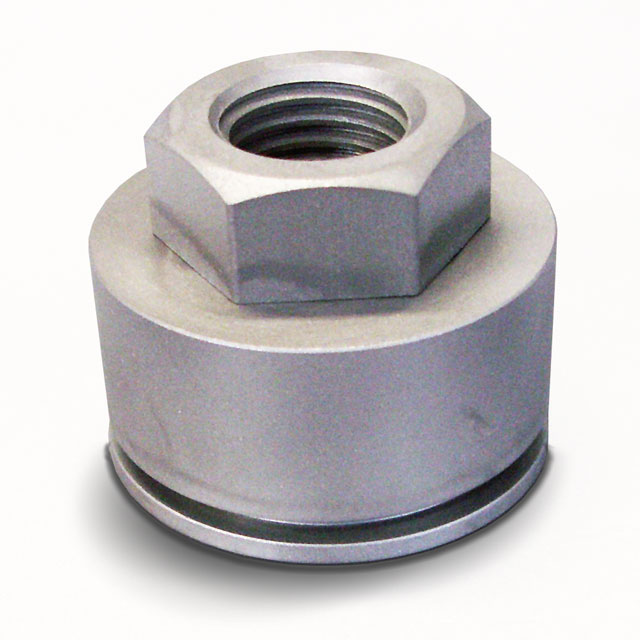

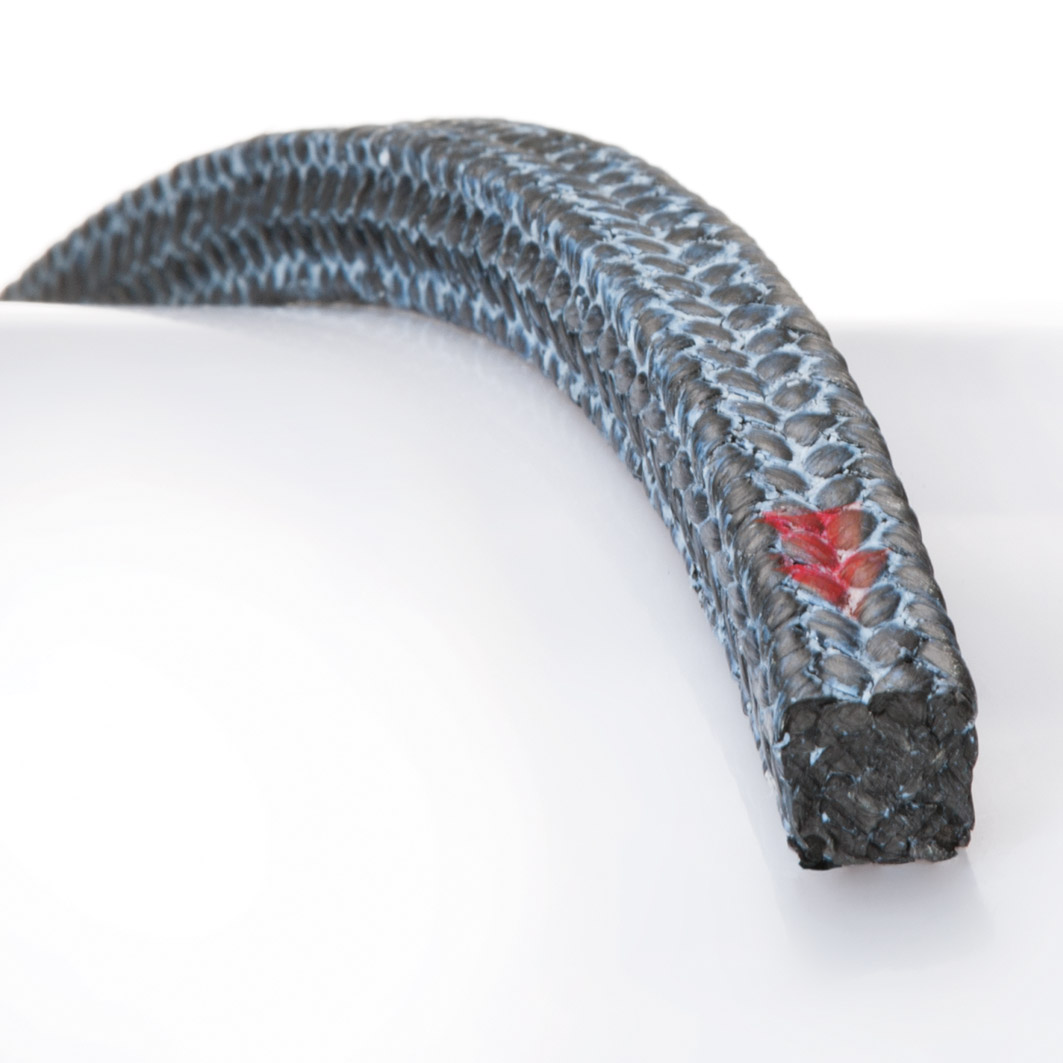

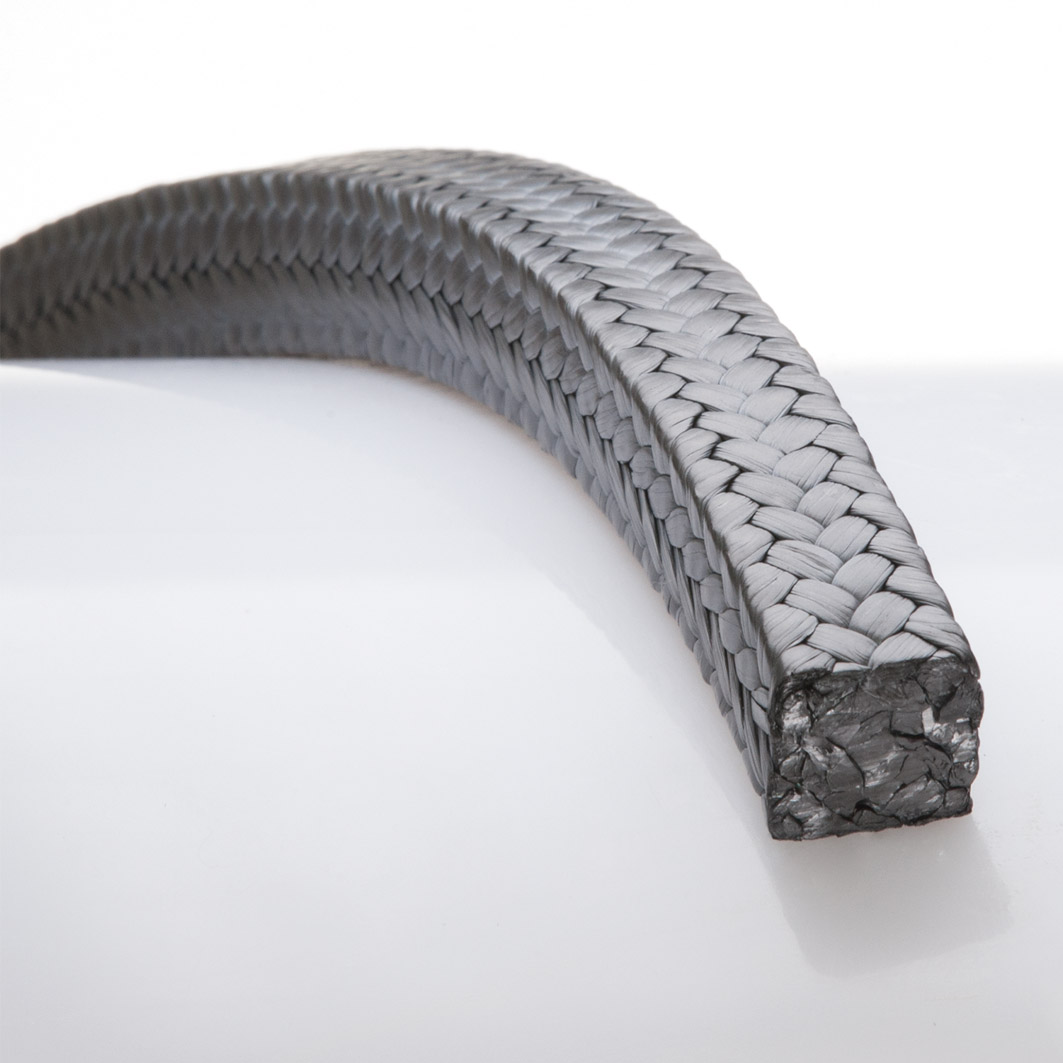

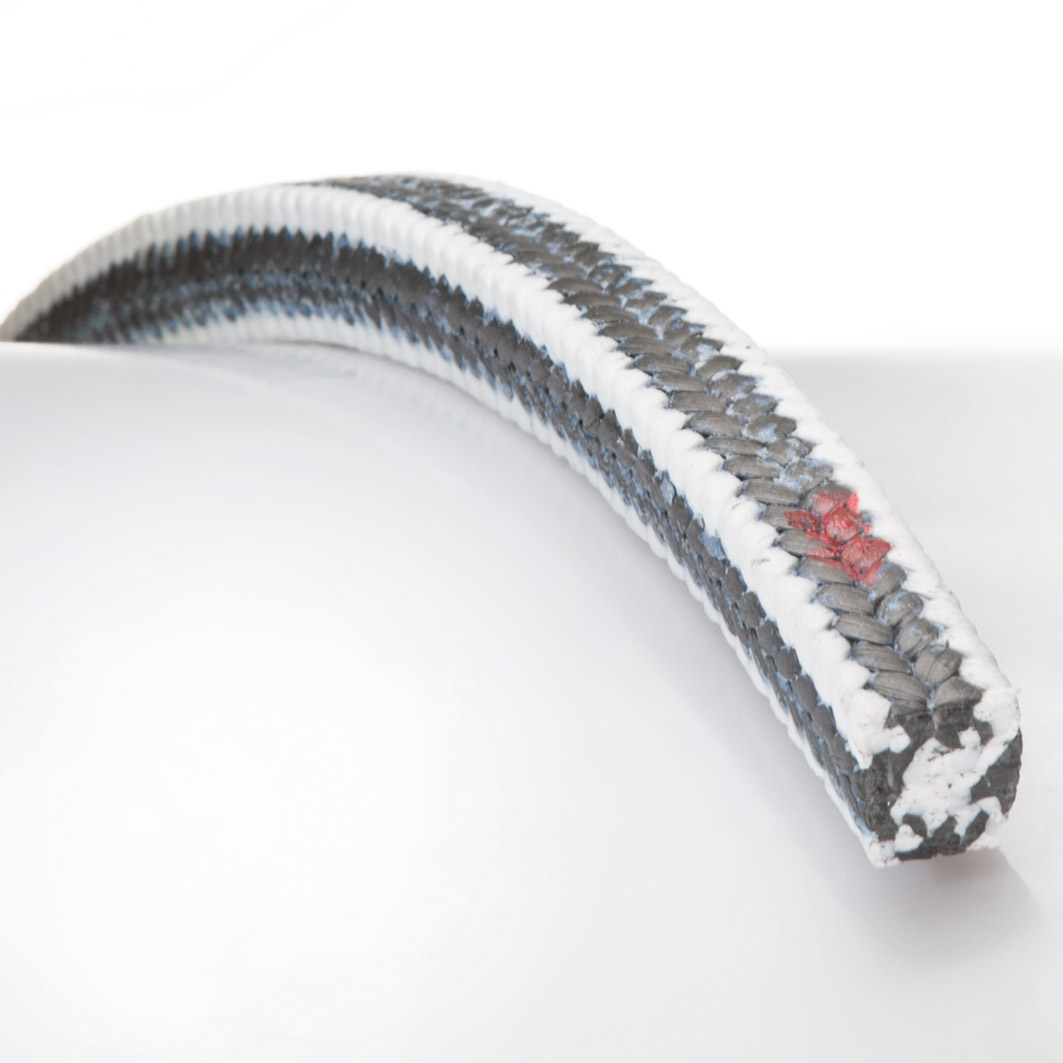

- Gland Packing

- Gland Packing Index

Gland Packing Index

A report on AES Engineering's sustainability strategy

Local Support

Get free product recommendations and mechanical seal reliability advice. From a wealth of local sales engineer support... We have experts in over 100 countries.

Find Our LocationsFor more information

Contact us for pricing and quotes, case histories, application engineering help, or anything else you need.

Contact us