Recently Published Videos

Filter by video type

Featured Videos

Welcome to the AESSEAL video section, use the menu above to navigate through the video sections, or stay on this page to explore featured videos from the AESSEAL video collections.

We Have a Heart

Our mission is clear. To stop the world from burning while keeping the wheels of industry turning. Join us in caring for the heart of industry and the planet.

Pressure and Temperature Sensor

The automatic floating pre-charge and fill pressure calculation performed by the System Sentry software enables simple set-up and refill of API 682 4th edition 53B systems.

Corporate Video

Journey of a Cartridge Seal

Seal Technology Training

Chris Rea Video Diary Box Set

Global Headquarters Tree Walk

Global Technology Centre Tour

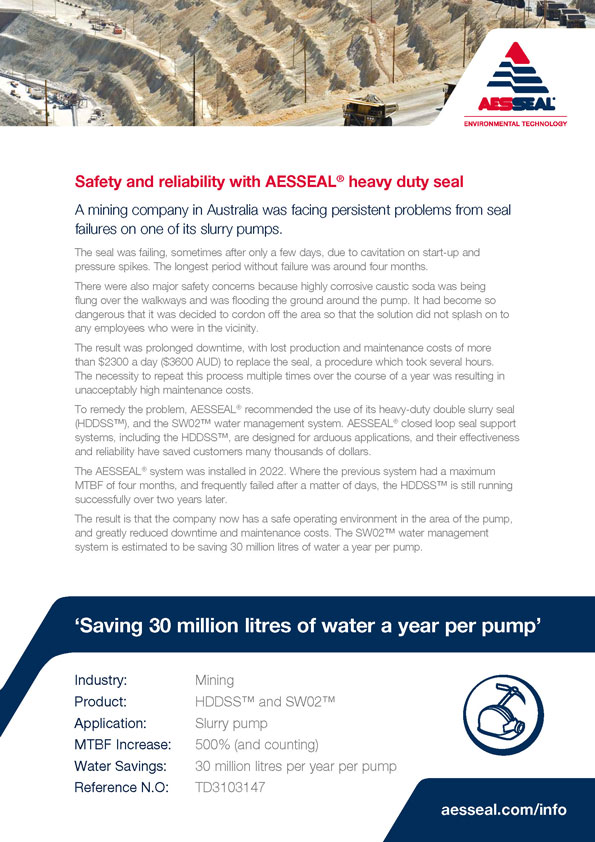

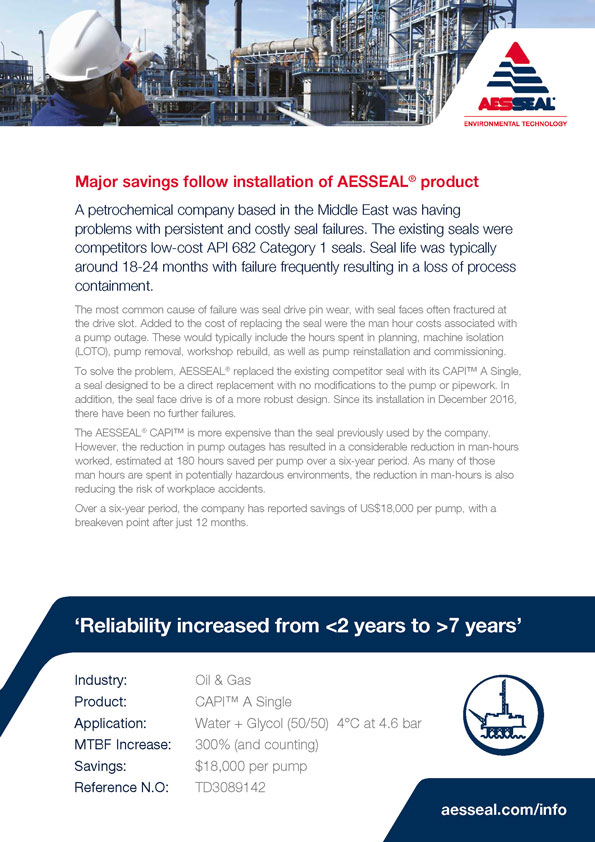

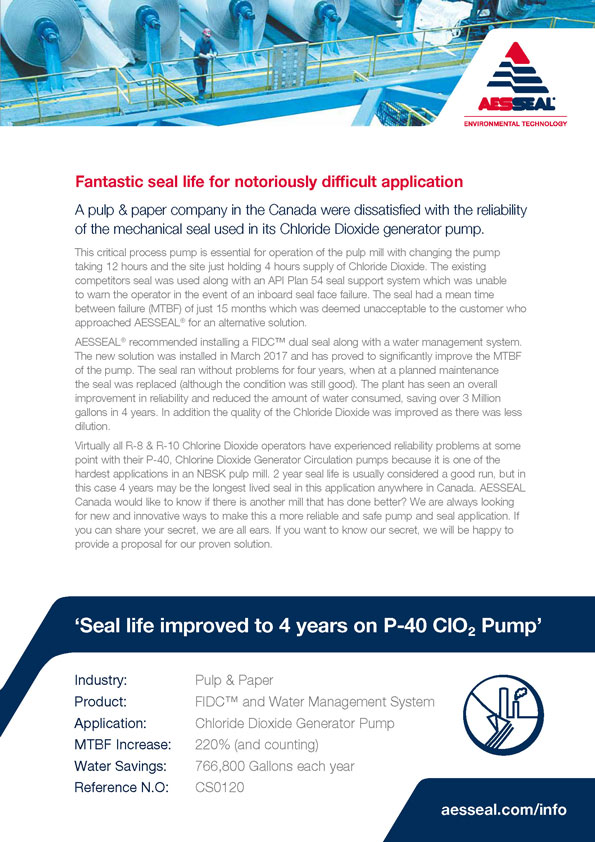

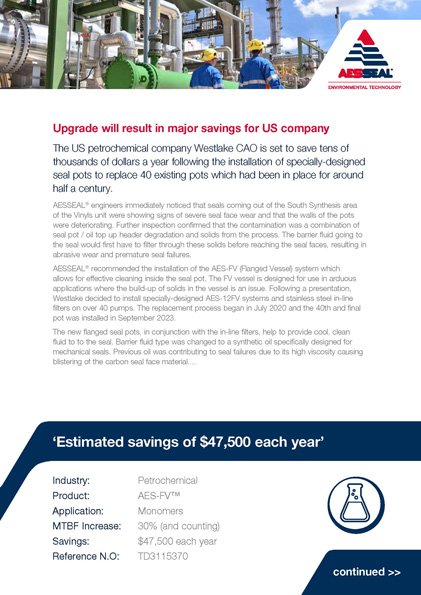

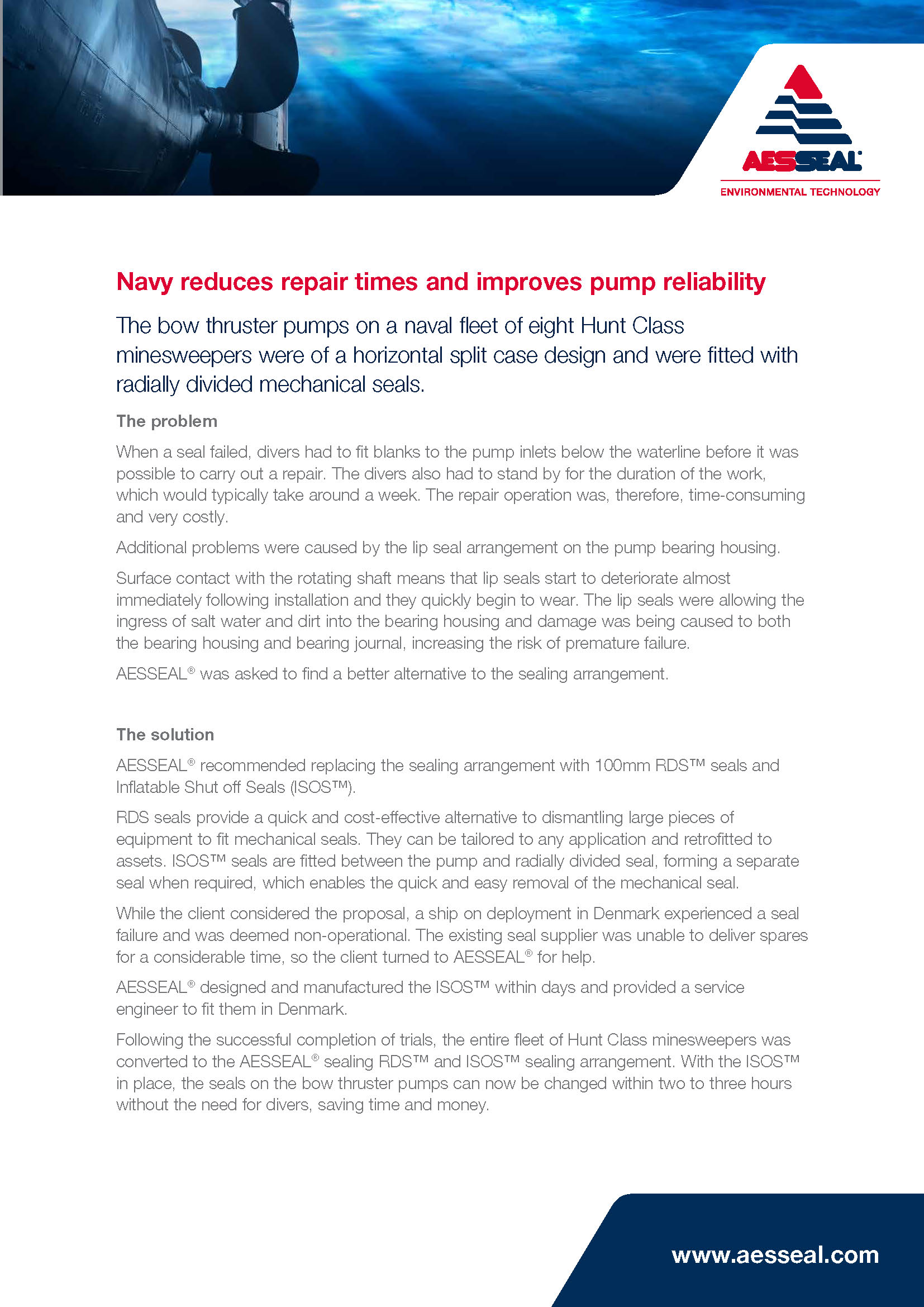

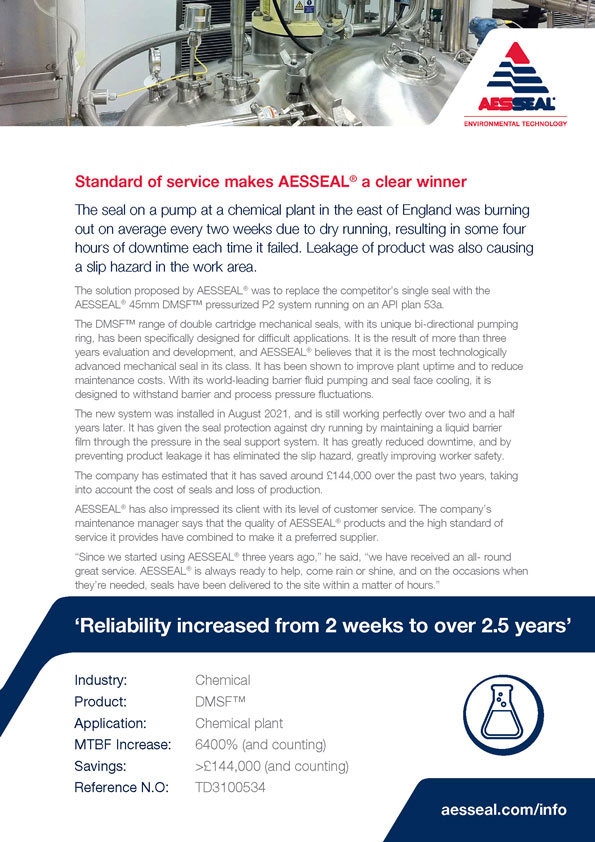

Featured Case Studies

The case studies below showcase the very best of commitment to excellence at AESSEAL across our three core pillars:

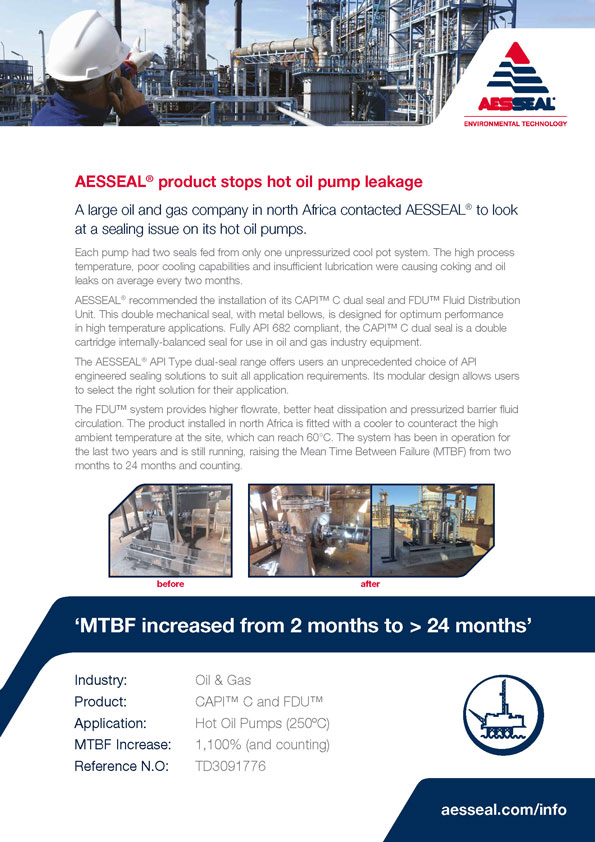

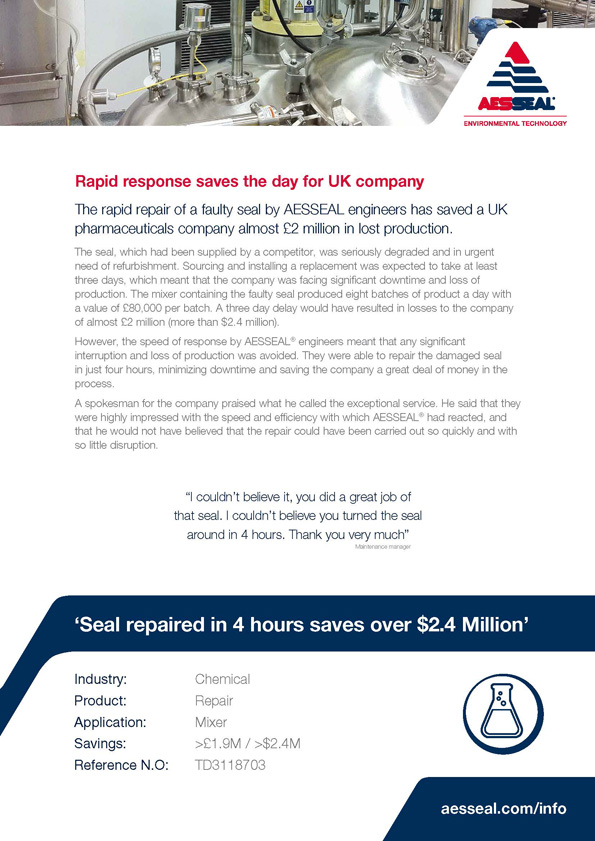

- Exceptional Customer Service – putting customers first, every time.

- Advanced Technology – delivering innovation that drives results.

- Sustainable Solutions – engineering a better future for people and our planet.

Sustainability Goals

AESSEAL® championing the needs of the environment, society and the economy.

AES Engineering Group is committed to providing a safe and rewarding workplace, operating ethically, supporting its local communities, minimizing its impact on the environment and engaging its stakeholders.

Watch the Journey to Net Zero

With Chris Rea's Video Diary Box Set

The AES Engineering Group has committed to invest £29 million on environmental projects between January 1st 2021 and April 1st 2029. The following videos are part of the commitment to report on the progress.

Watch the VideosA Tour of the Facilities

Get an in-depth look at our facilities and see how we are able to deliver what is probably the best customer service in the industry.

YouTube Video Series

AESSEAL® provides the best environmental technology solutions for your turbomachinery assets.

Our dry gas seal repair program supports all of our customers, regardless of the original equipment manufacturer. We will show you around our world class facility, giving an insight in to how we build, test and repair dry gas seals. We are a superior quality manufacturer focusing on quality and exceptional customer service.