Oil & Gas Case Studies

Reliability guaranteed with installation of LabTecta AX

Prompt delivery saves three-month delay

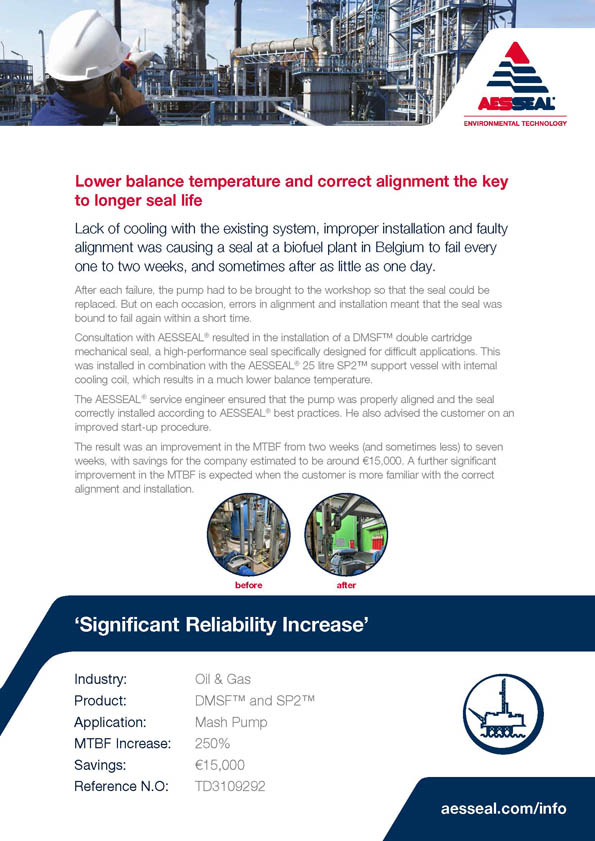

Lower balance temperature and correct alignment the key to longer seal life

Rapid response impresses Saudi customer

STS seal and LabTecta ST ends steam leak hazard

System Sentry proves its worth in INEOS field trial

Engineers at the petrochemicals manufacturer INEOS have given the seal of approval to the AESSEAL® monitoring device System Sentry® following a field trial at the company’s plant in Hull in the east of England.

AESSEAL achieves major savings for Middle East oil producer

An oil and gas company in the Middle East is saving more than $600,000 a year following the installation of an AESSEAL® product.

Major savings follow installation of AESSEAL product

A petrochemical company based in the Middle East was having problems with persistent and costly seal failures.

STS steam seal updates UK Ethylene plant

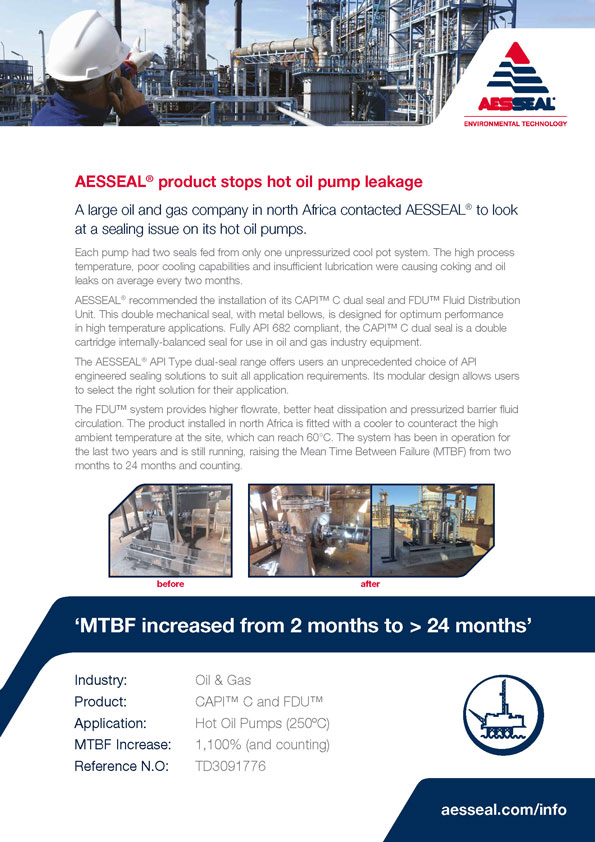

AESSEAL product stops hot oil pump leakage

UK oil refinery close to shutting down following labyrinth seal failure

AESSEAL lowers the temperature in Montana

AESSEAL system eliminates danger of hydrogen sulfide release

Full steam ahead for refinery after change to STS seals

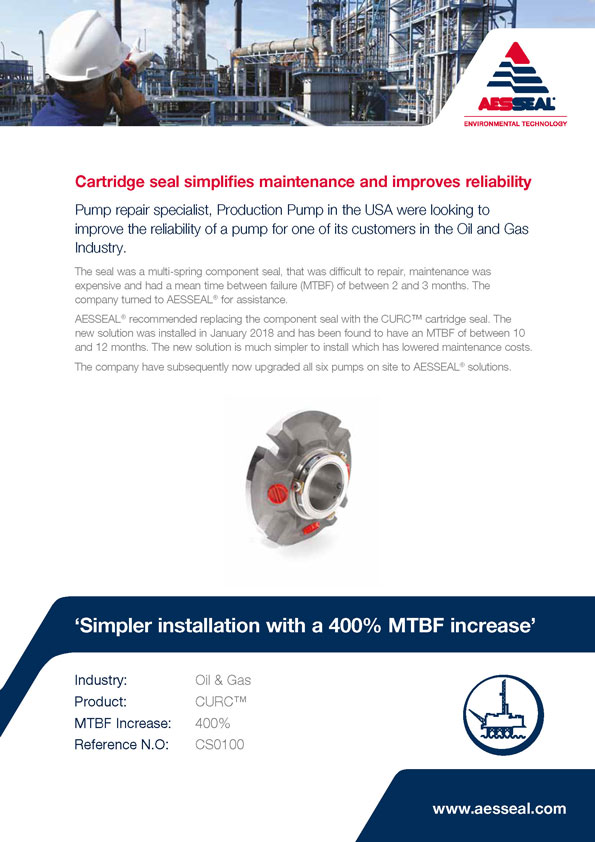

Cartridge seal simplifies maintenance and improves reliability

6 times improvement in MTBF for Upstream water injection pump

Improved reliability for new process

Seal upgrades save over US $3.4million in seven years

Seal upgrade improves reliability and saves over US$81k

MagTecta improves cooling tower fan reliability

MagTecta improves gearbox reliability

Seal upgrade improves pump availability

Fast delivery, reliable solutions.

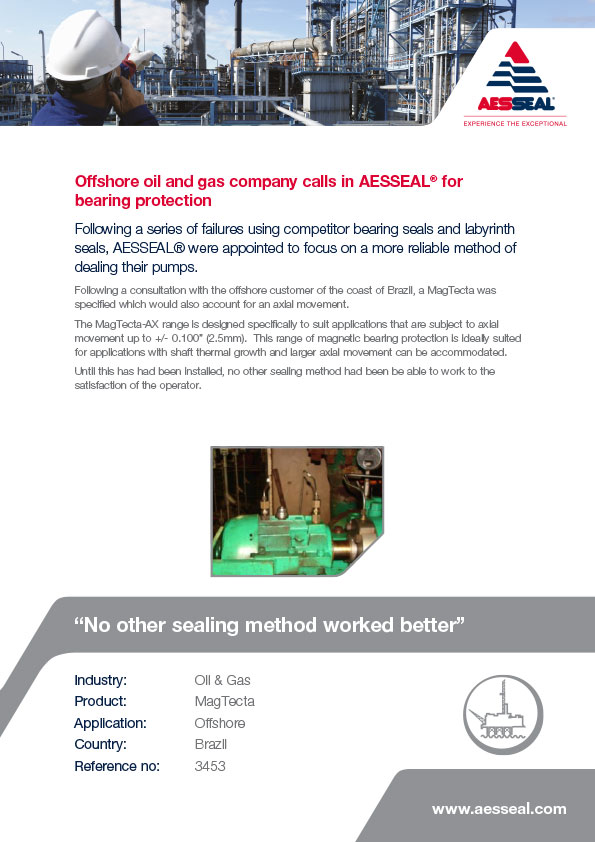

Offshore oil and gas company calls in AESSEAL for bearing protection

Lip seal upgrade for US petrochemical plant

Salt water spray contamination eliminated by bearing protection

New orders follow success of AESSEAL installation

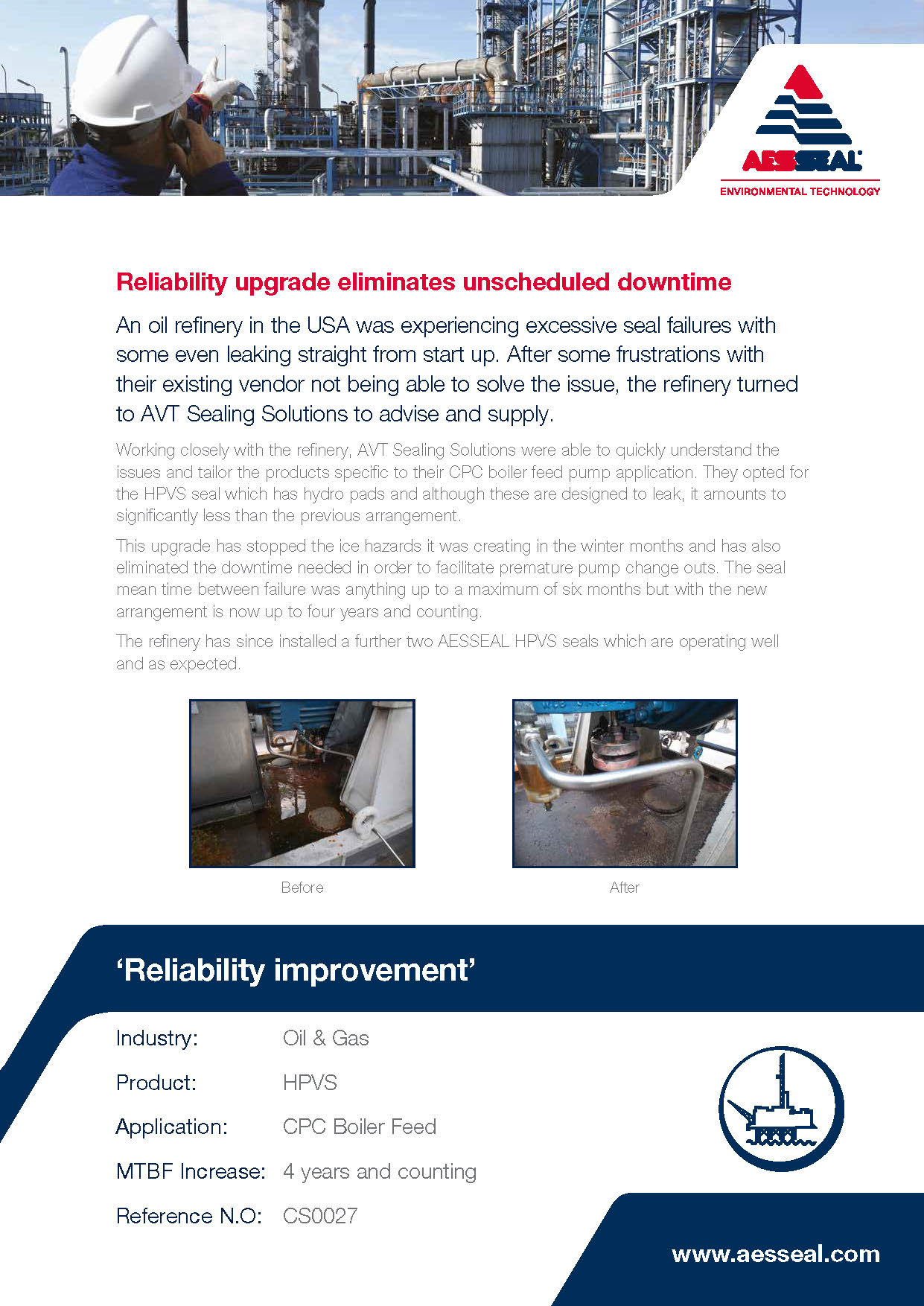

Reliability upgrade eliminates unscheduled downtime

MTBF increases by 233%

Improved pump reliability for oil refinery

Increased reliability saves over 1,500,000 ZAR

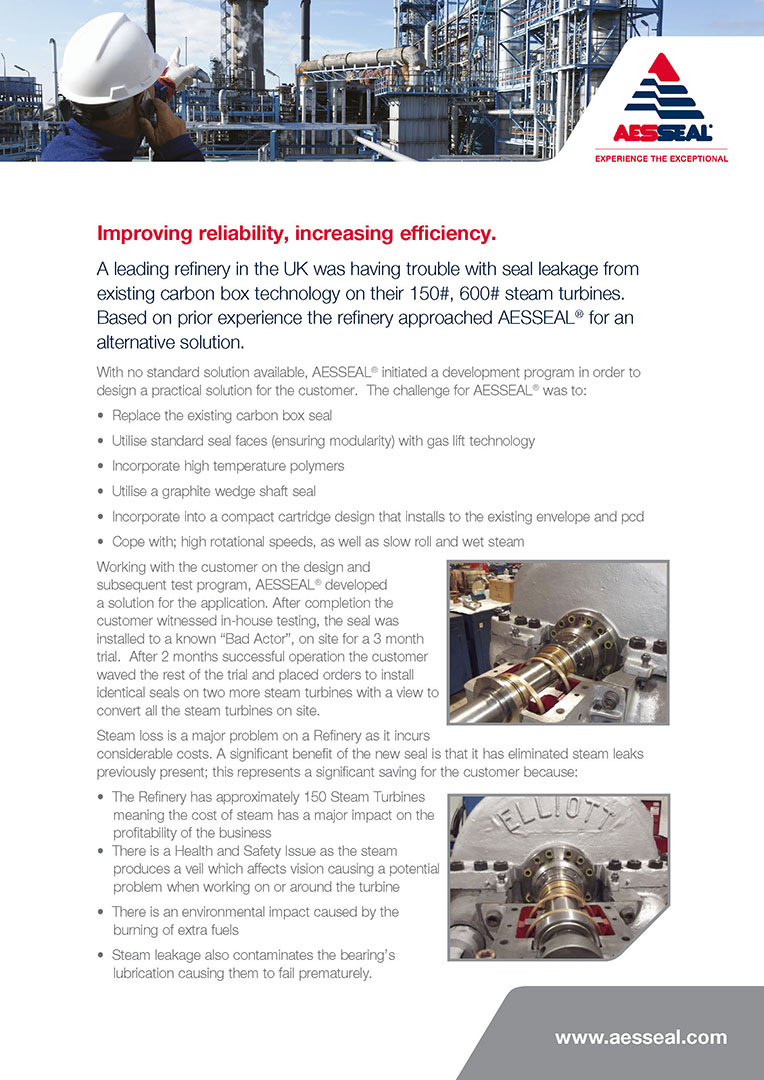

Improving reliability, increasing efficiency

Preventing steam ingress into the bearing housing

AESSEAL help a Polyethylene plant save €144,000 in 30 months

Unbeatable lead times on bearing protection